Wheel crane mobile counterweight

A technology of wheeled crane and counterweight frame, which is applied to cranes and other directions, can solve the problems of boom length, luffing and hoisting weight restrictions, and achieve the effect of not affecting passability and safety, and improving driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

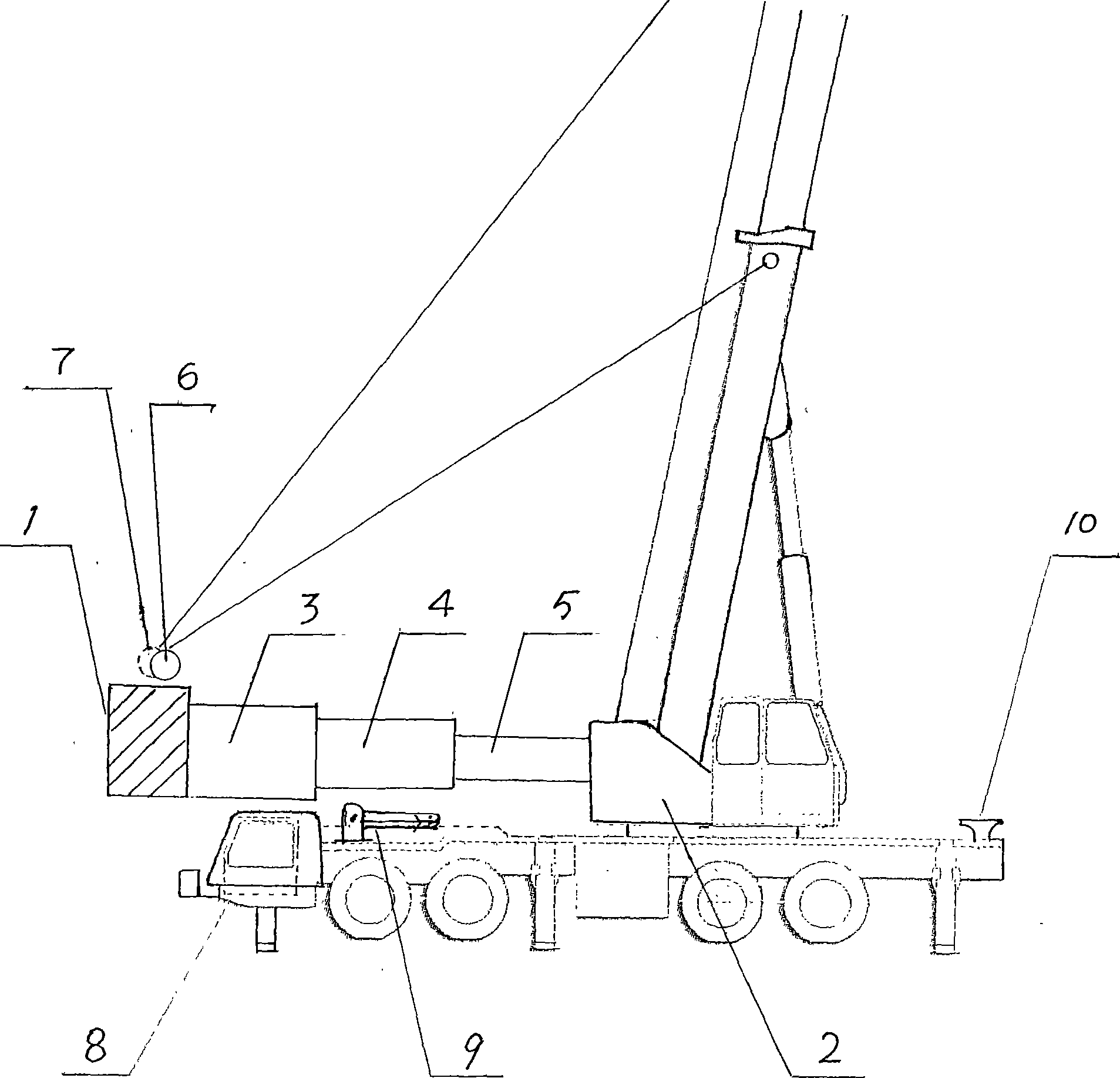

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] As shown in the picture: after the wheeled crane arrives at the work site, after putting down the outriggers, the following steps can be followed

[0026] 1. Lower and shrink the cab 8, and loosen the counterweight fixing device 10.

[0027] 2. According to the movable boom to be used, install the movable boom hoist 7 steel wire rope at the arm end.

[0028] 3. Raise the boom and put down the folding boom support 9.

[0029] 4. Move the counterweight 1 along with the counterweight frame 3 along the telescopic counterweight frame 4 and the fixed counterweight frame 5 to a suitable position according to the requirements of the hoisting weight, boom height and amplitude, and obstacles within the radius of gyration.

[0030] 5. During the operation, the main boom hoist 6 and the movable boom hoist 7 tighten or loosen the wire rope synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com