Air purifier filtration apparatus and production method thereof

An air purifier and filter device technology, applied in chemical instruments and methods, membrane filters, separation methods, etc., can solve the problems of bending and deformation of wave parts, poor filtering effect, complex production process, etc., to avoid bending Deformation, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

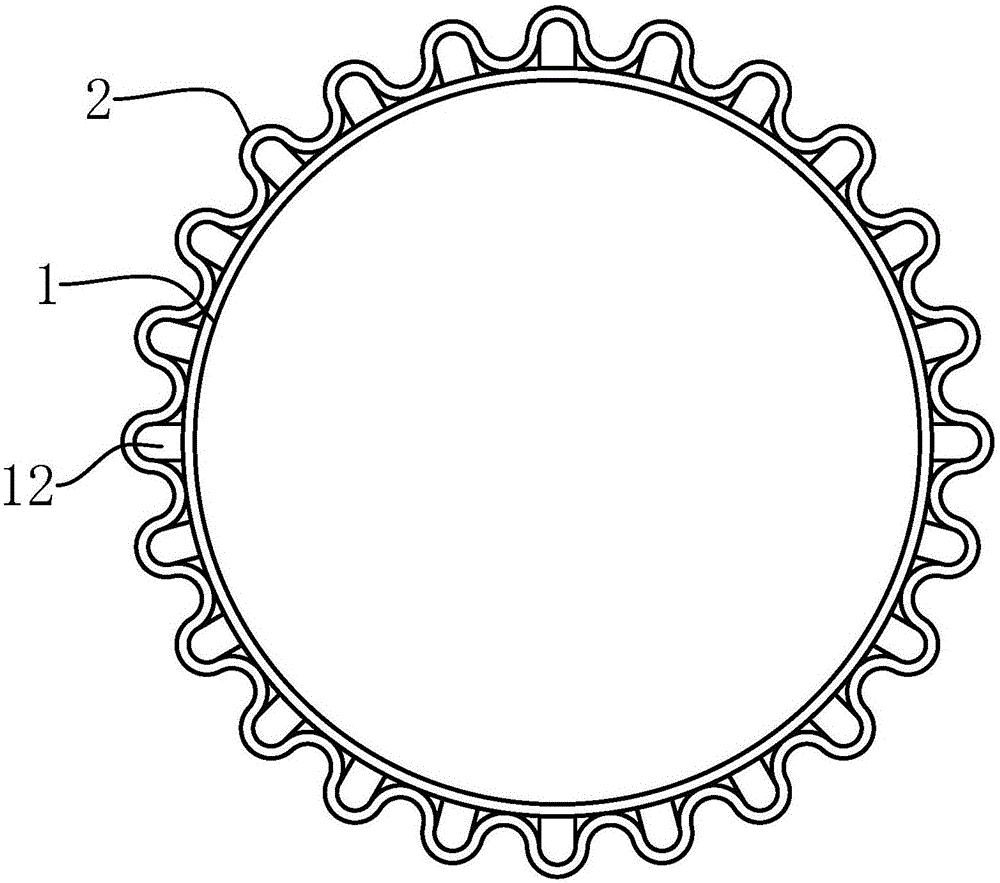

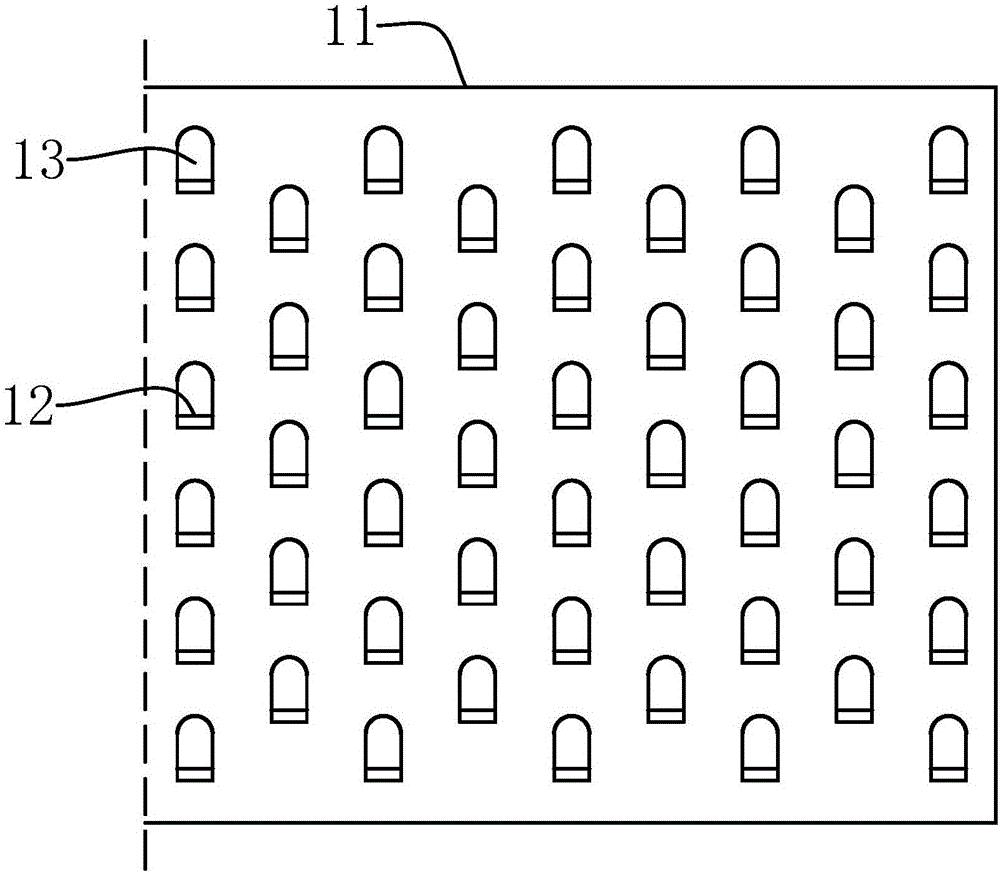

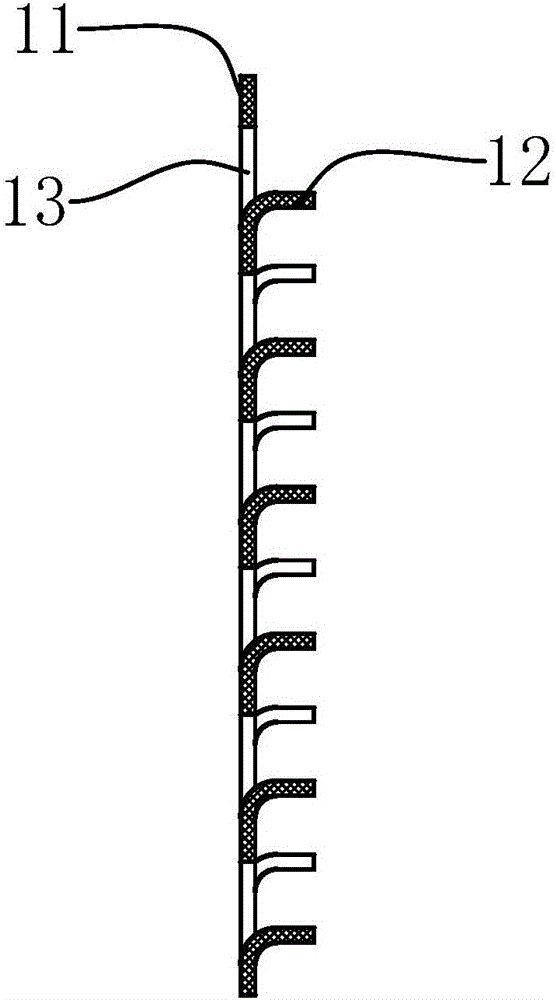

[0028] Such as figure 1 As shown, an air purifier filter device of the present invention includes a cylindrical support tube 1, the support tube 1 is a thin plate structure, and the outer wall of the support tube 1 is provided with a number of support pieces 12 with a scale-like structure, perpendicular to the axis of the support tube 1 The cross-section of the supporting cylinder 1 is parallel to the upper and lower surfaces of the supporting piece 12, and several supporting pieces 12 are distributed in an array on the outer wall of the supporting cylinder 1, and a row of supporting pieces 12 along the axial direction of the supporting cylinder 1 are equidistantly aligned and distributed along the circumference of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com