Welding process for ensuring smooth transition and molding of ellipsoidal circular seam and auxiliary welding clamp thereof

A welding process and smooth transition technology, applied in auxiliary welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems affecting the charge amount and performance of the shell, so as to adapt to mass production and the method is simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

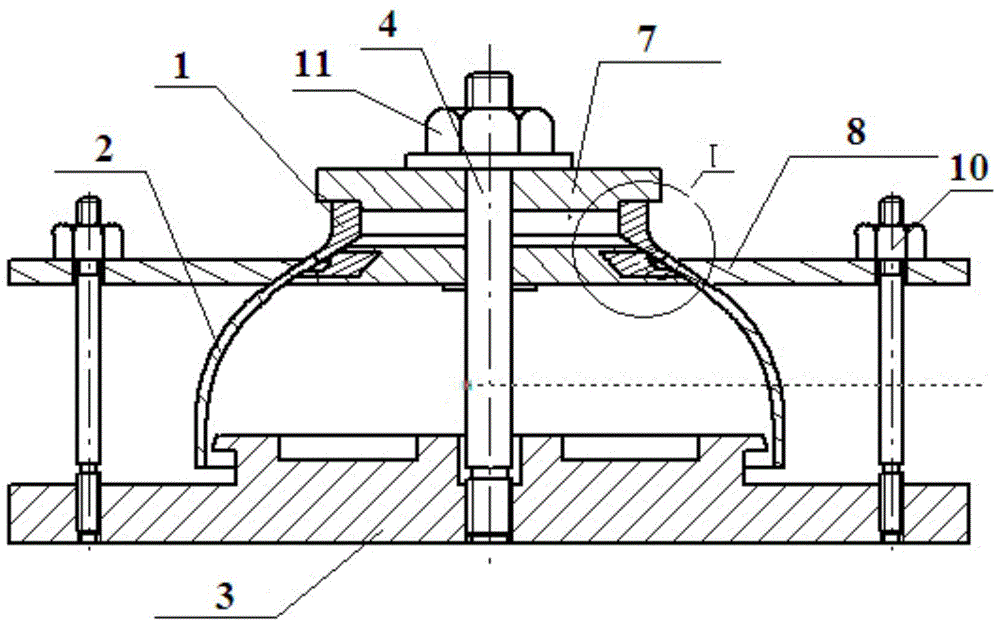

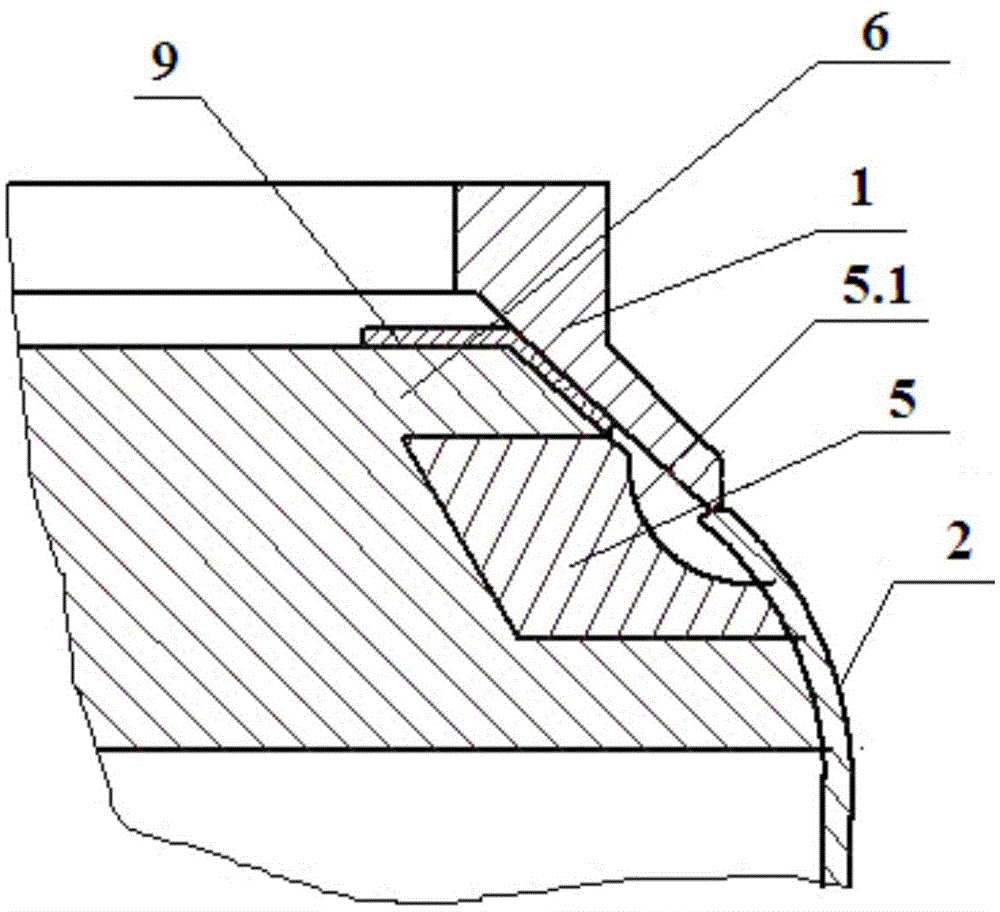

[0027] figure 1 It is the auxiliary welding jig and assembly diagram of the present invention. figure 2 It is a partial enlarged view of the shell joint and the girth weld of the ellipsoid.

[0028] From figure 1 , 2 It can be seen that before welding the combustion chamber shell joint 1 and the ellipsoid 2, the welding groove of the misaligned butt joint must be preset first, and the structure is as follows figure 1 , 2 As shown, the end faces of the ellipsoid 2 and the shell joint 1 to be welded have a blunt edge of 1mm and a unilateral bevel of 36° to ensure that the cross-sectional diameter of the shell joint 1 is Greater than the cross-sectional diameter of the ellipsoid 2, that is, the downward projection of the inner wall of the ellipsoid 2 at the joint is located on the inner surface of the downward projection of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com