Fuel component and fixing method for liquid heavy metal cooling reactor

A technology of liquid heavy metals and fuel components, applied in the direction of fuel elements, assembly of fuel elements, reduction of greenhouse gases, etc., can solve problems such as reducing reactor economy and increasing reactor coolant consumption, so as to improve reliability and safety, structure The effect of simple, simple refueling operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

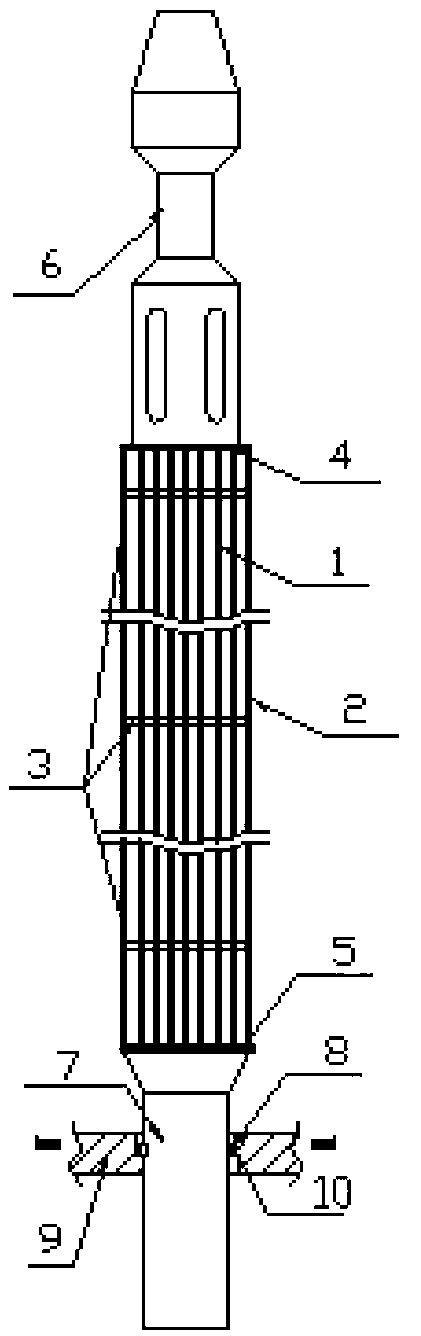

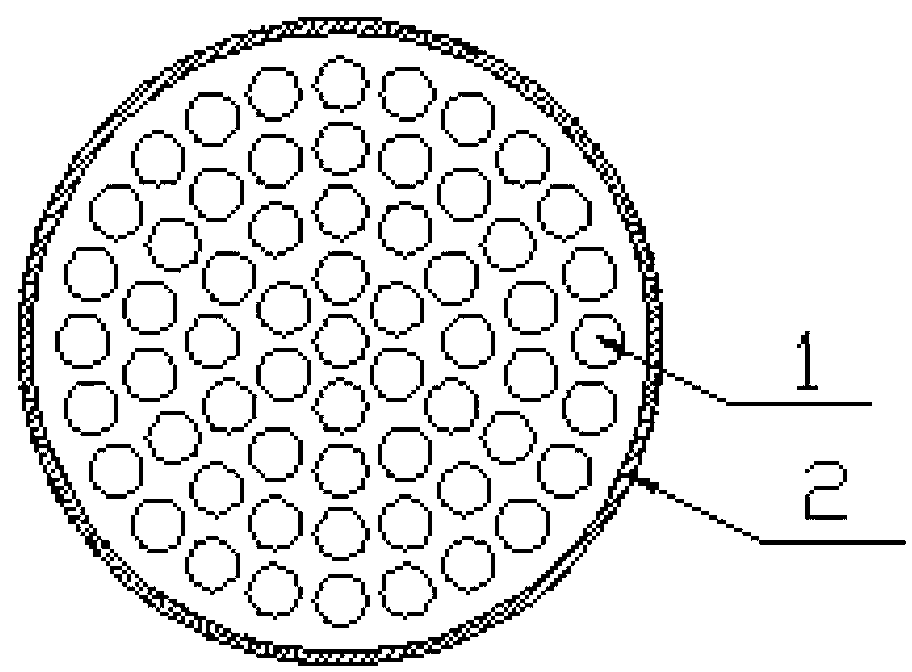

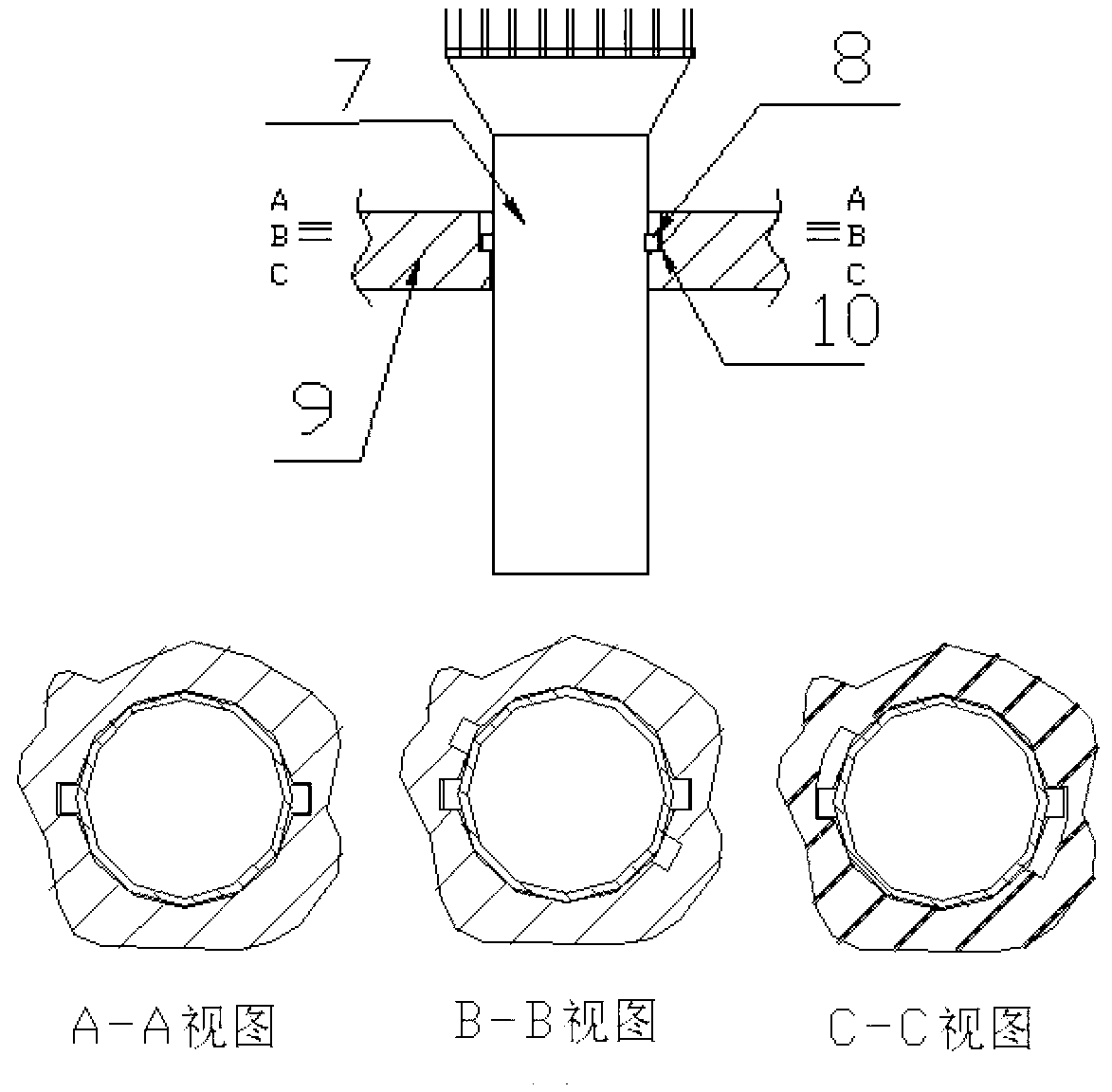

[0016] Such as figure 1 As shown, the fuel assembly of the present invention is made up of fuel rod 1, assembly casing 2, positioning grid 3, upper grid 4, lower grid 5, operating head 6, pin 7 and positioning frame 8, and is characterized in that it adopts The casing of the circular assembly, the fuel rods are arranged in a circular shape, and the pins are provided with a positioning frame. The positioning grid 3 is located in the middle of the bundle of fuel rods 1 and plays the role of positioning the fuel rods 1. The specific number can be adjusted according to the design of the specific reactor. The upper grid 4 and the lower grid 5 are respectively arranged with the upper end and the lower end of the fuel rod 1 bundle, and the fuel rod 1 is fixed therein. The operating head 6 is located at the upper end of the fuel assembly, and is used to match the refueling mechanism when refueling the reactor. The pin 7 is located at the lower end of the fuel assembly, and the pin 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com