On-line monitoring method for heat efficiency of boiler based on coal quality database

A boiler thermal efficiency, boiler efficiency technology, applied in the direction of electric digital data processing, special data processing application, boiler working status indication, etc., can solve the problems of large error, unable to be popularized and applied, large error of online analysis of coal combustion composition, etc. , to save energy, avoid divergence of calculation results, and reduce large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

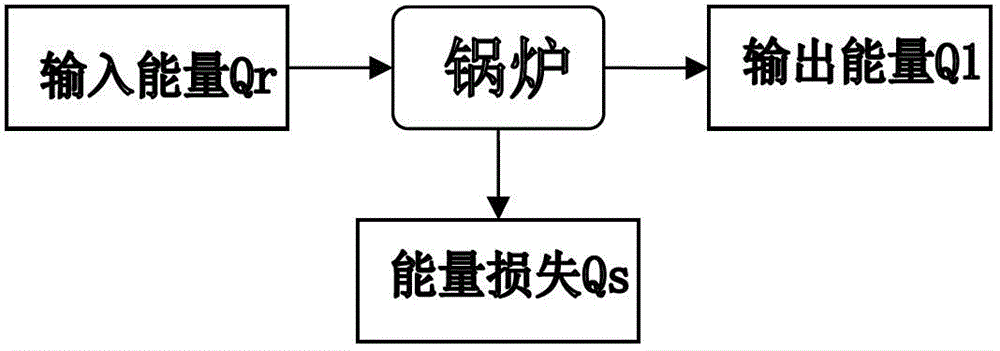

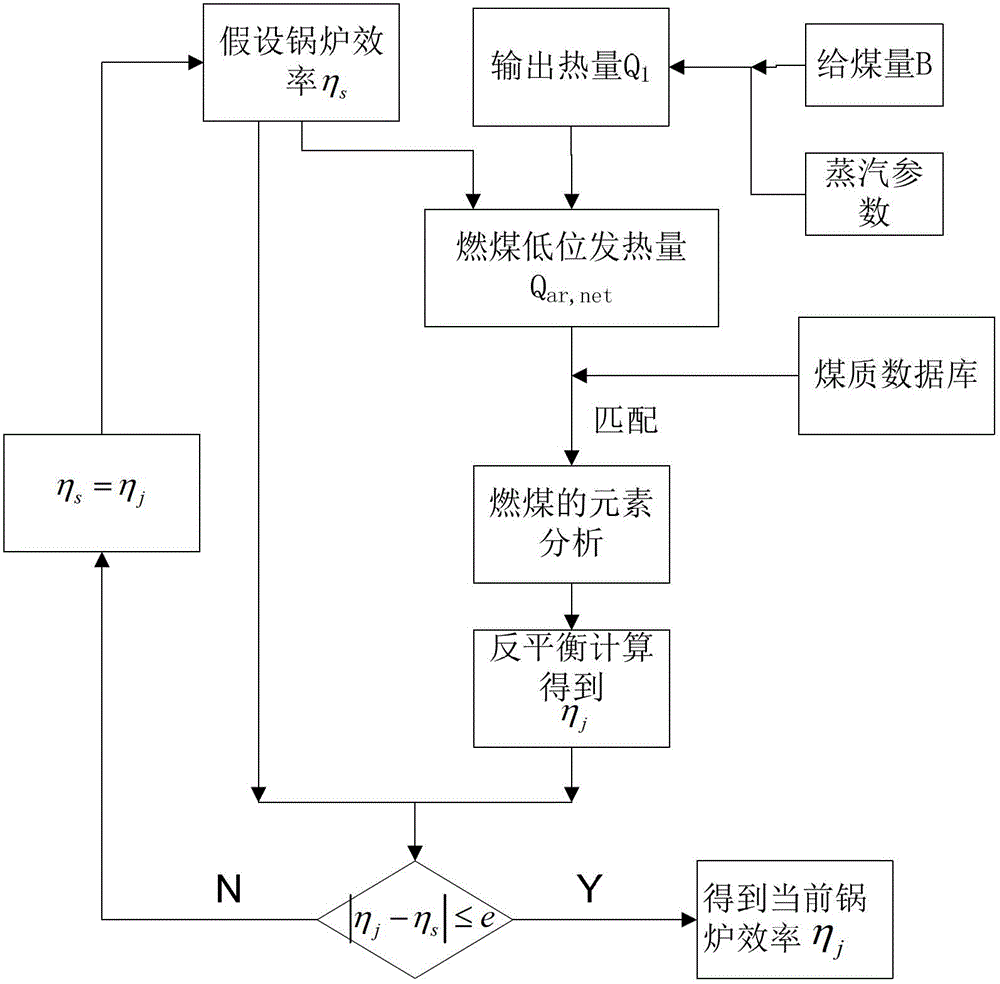

[0039] See figure 1 , figure 2 As shown, the present invention is a method for online monitoring of boiler thermal efficiency based on a coal quality database. The implementation of the method is as follows, and the specific calculation process is shown in the attached figure 2 :

[0040] (1) The output energy Q of the boiler can be calculated according to 6.2.2 of the GB10184-88 standard 1 .

[0041] (2) Assuming a boiler efficiency η s , according to formula (3), the input energy Q can be obtained r ,Right now

[0042] (3) According to Find the corresponding coal composition in the coal quality database.

[0043] (4) According to the obtained coal composition, conduct Q in accordance with GB10184-88 or DL / T 964-2005 s Calculated, and the calculated boiler efficiency η is obtained from formula (2) j , when the boiler efficiency η is obtained j with η s When the difference is less than e (take e=0.05), it is considered that η j is the actual efficiency of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com