Over-temperature risk indicator-based boiler heating surface monitoring method

A risk index and heating surface technology, which is applied in the field of thermal power plant boiler heating surface overtemperature monitoring, can solve problems such as large differences, and achieve the effect of optimizing the maintenance plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] The steps of the present invention are as follows:

[0042] 1) Build boiler heating surface parameters and wall temperature measuring point information table;

[0043] 2) According to the material type of the furnace tube on the heating surface, set the wall temperature alarm threshold of each section of the furnace tube;

[0044] 3) Read the wall temperature data of the heating surface in real time;

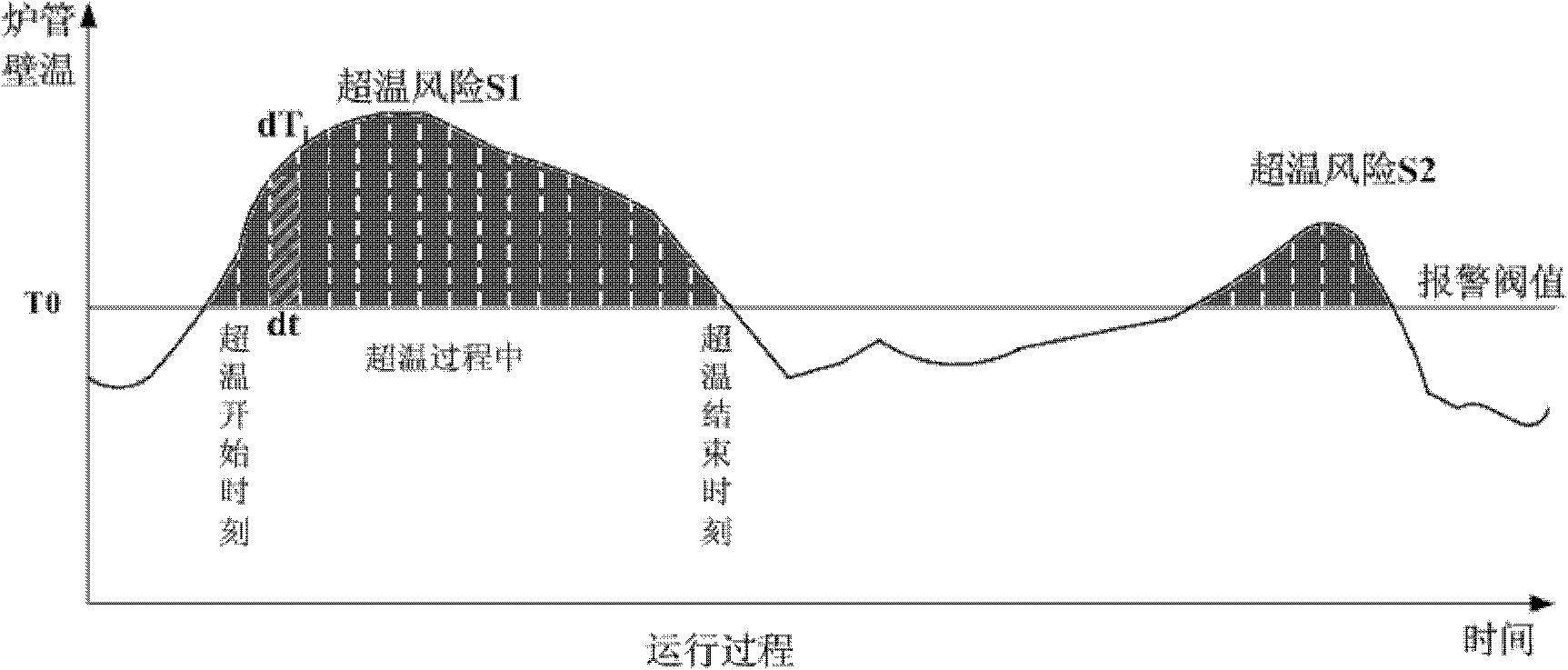

[0045] 4) Judgment of data status: just start over-temperature, go to 5); during over-temperature process, go to 6); end over-temperature, go to 7); if the data is normal, go to 3);

[0046] 5) Form a new overrun record and record relevant information;

[0047] 6) Calculate the over-temperature risk value of this over-temperature, and accumulate the over-temperature risk value of this part, and transfer to 3);

[0048] 7) End this overrun, form a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com