Combustion energy-saving automatic control device of coal-burning chain boiler

A technology of automatic control device and chain boiler, which is applied to control systems, steam boilers, steam boiler accessories, etc., can solve the problems of low operating pressure of combustion boilers, low quality of operators, and unmatched loads, so as to reduce emissions and reduce The effect of equipment investment and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

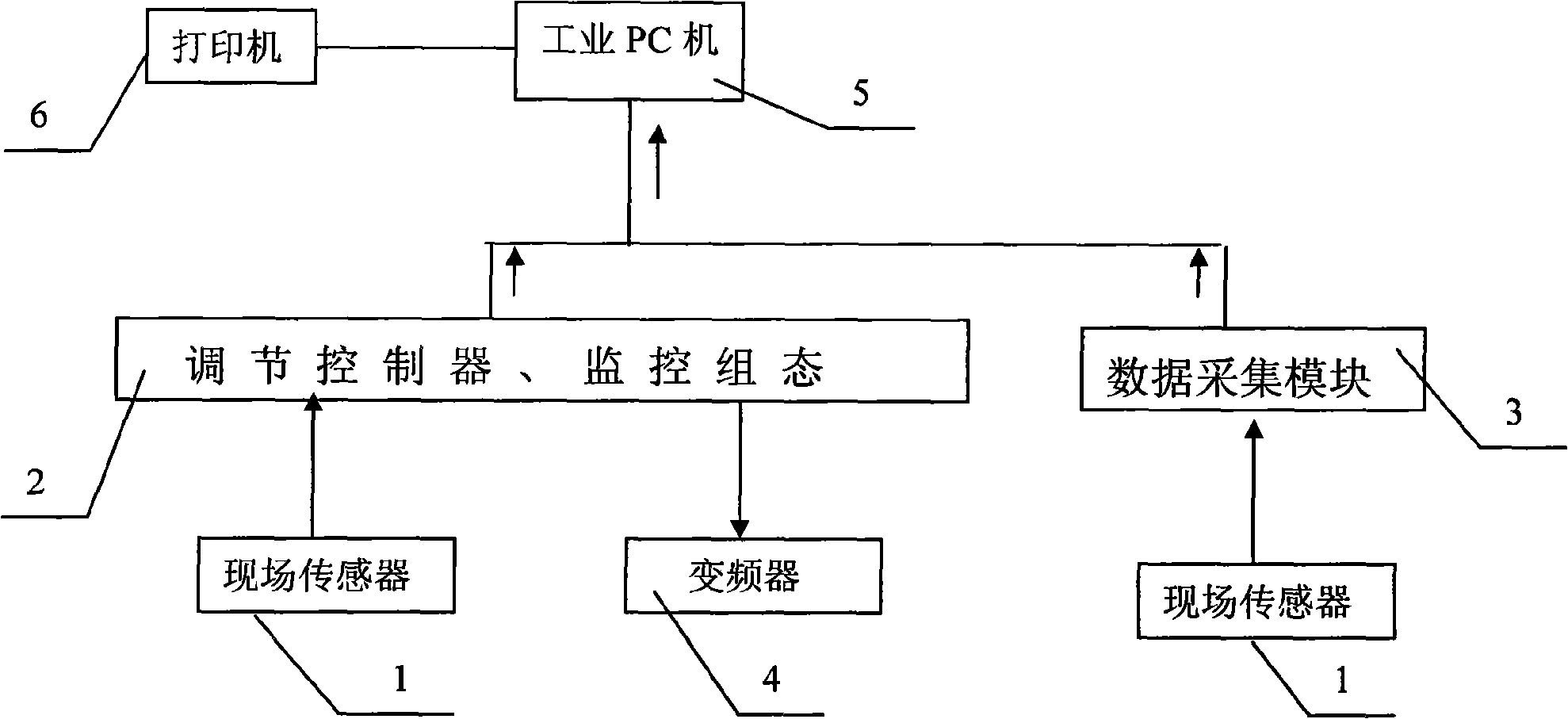

[0016] Example 1, see figure 1 , on-site sensor 1 is installed on the coal-fired chain boiler. The on-site sensor 1 includes on-site sensors such as drum water level, steam pressure, furnace negative pressure, flue gas oxygen content, and deaerator. The controller and monitoring configuration 2 are connected, and the adjustment controller is preset with a certain program. At the same time, the field sensor 1 is connected to the data acquisition module 3 through the line, and the adjustment controller and the monitoring configuration 2 are connected to the frequency converter 4 through the line to form a The liquid level closed-loop control system composed of the on-site sensor 1, the regulating controller, the monitoring configuration 2 and the frequency converter 4; the regulating controller, the monitoring configuration 2 and the data acquisition module 3 are respectively connected with the industrial PC 5 The PC 5 is connected with the printer 6 through a line, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com