An on-line safety assessment method of water wall

A technology for safety evaluation and water cooling wall, which is applied to instruments, computer control, simulators, etc. It can solve the problems of large error value of results, dependence on a large number of empirical parameters, and expansion of flow deviation, etc., and achieves the effect of small CPU usage and high algorithm accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

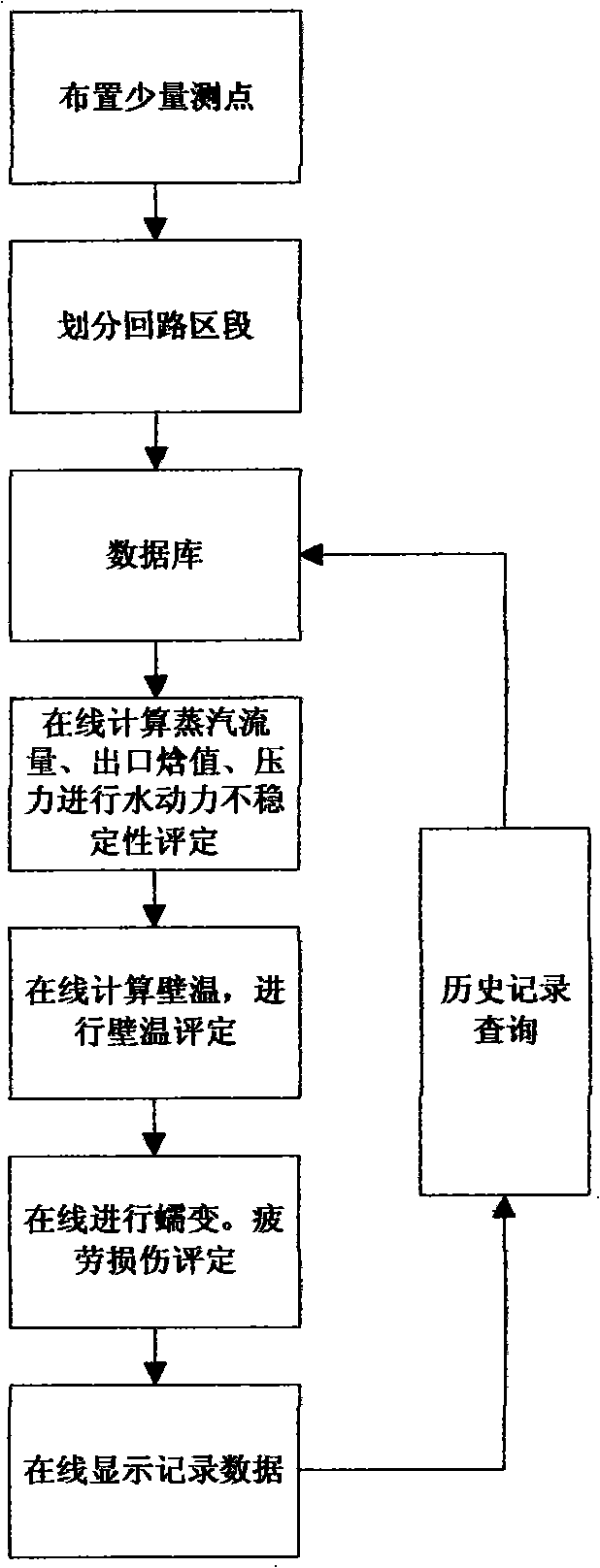

[0051] Due to the constraints of technology, the traditional measurement method cannot set a large number of measuring points in the furnace to measure the real-time changes of the working conditions of the entire furnace; the arranged measuring points cannot be located on the pipe section with the highest wall temperature, and the pipe wall often appears. The over-temperature position is not monitored; at the same time, the calculation relies on a large number of empirical parameters, which makes the error value of the calculated result too large.

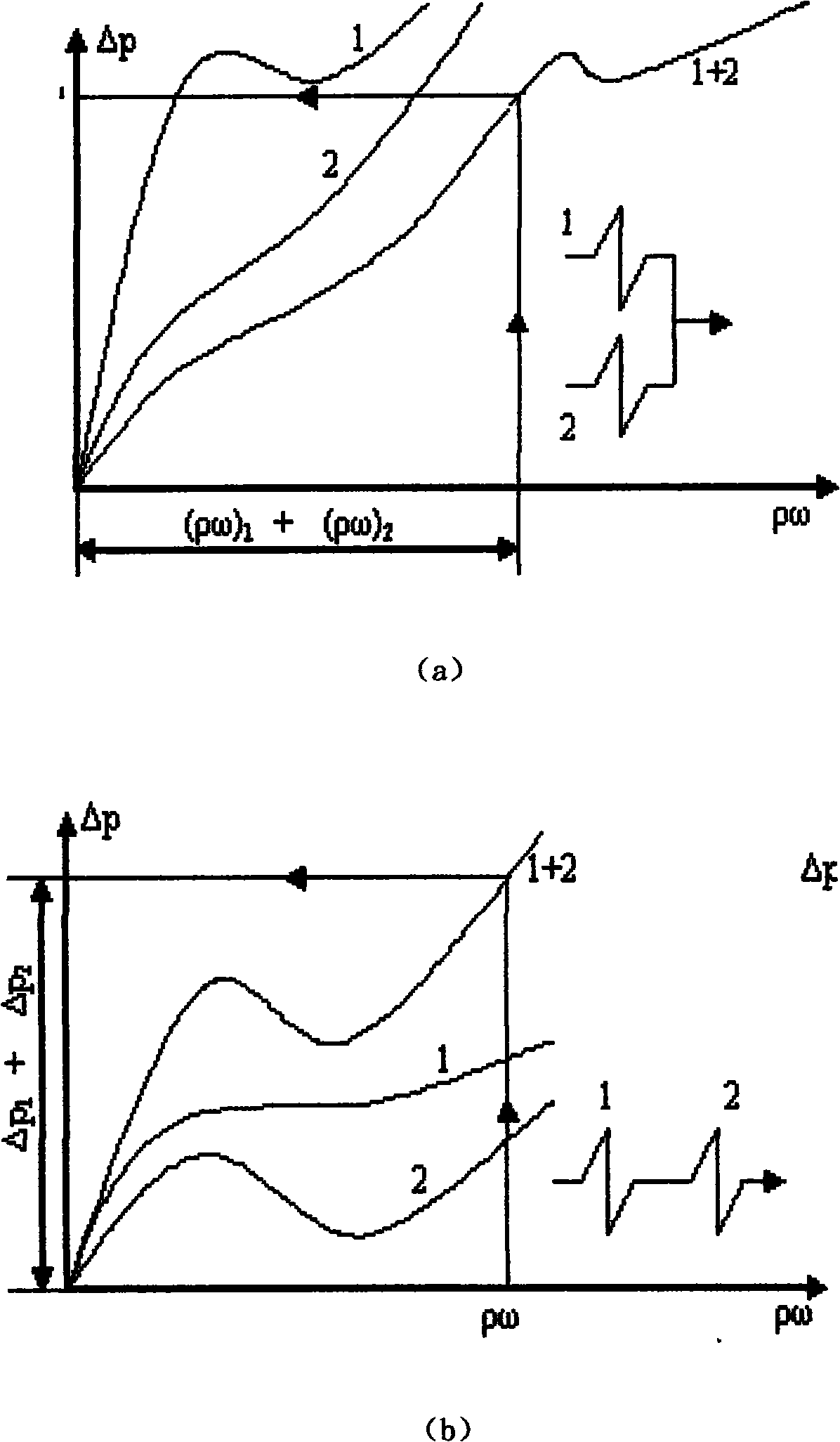

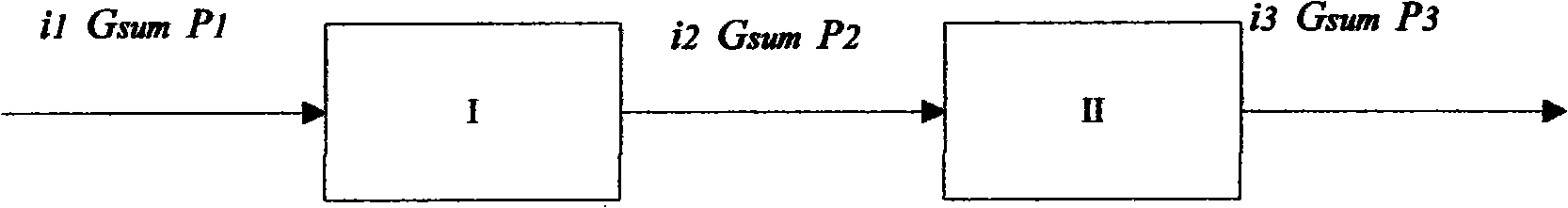

[0052] In view of the above problems, the water wall on-line safety evaluation method of the present invention is based on the dynamic analysis of a small number of measured characteristic parameters in the tube and the calculation of flow heat transfer in the tube. coefficient), calculate the flow rate of each loop under each load rate online, and then calculate the outlet steam temperature, pressure, wall temperature, calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com