Electronic vaporiser system

a technology of electronic vaporizer and electronic vaporizer, which is applied in the direction of special dispensing means, rigid containers, immersion heating arrangements, etc., can solve the problems of complex user interaction, simple and attractive rituals, and the complex design of conventional re-fillable e-cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

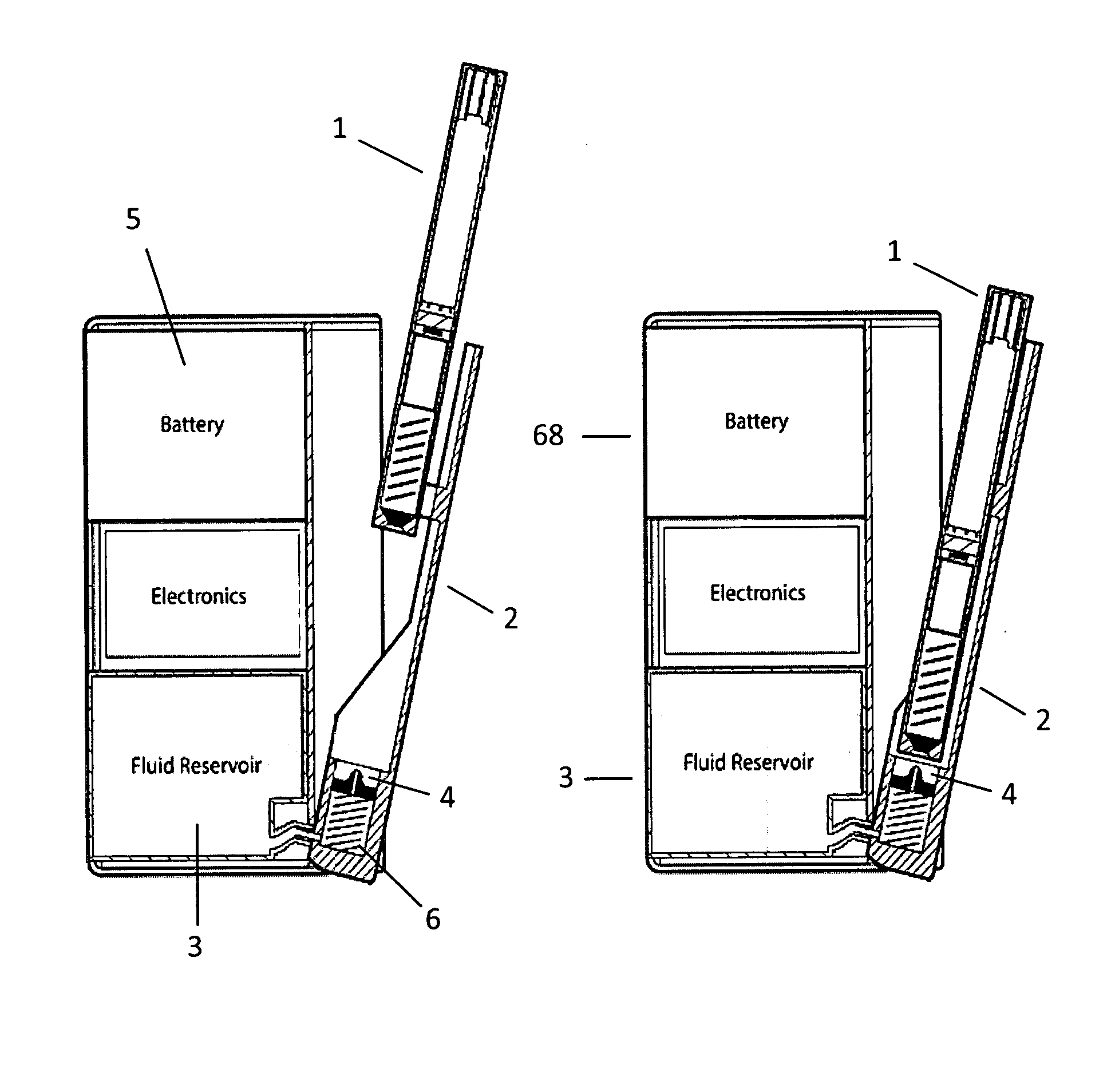

Method used

Image

Examples

case feature 2

Case or PV has a ‘Discrete’ Mode:

[0243]PV includes a ‘discrete mode’—e.g. to reduce the amount of vapour produced, the user can activate a button or sensor on the PV (or case, or connected app) and that alters the operation of the operation of the atomising device in such a way as to decrease the vapour produced—for example, it could reduce the power used, or increase the VG proportion compared to PG, if that is possible—e.g. the case or PV can mix differing proportions of PG and VG, or alter the frequency or other operational parameters (e.g. duty cycle) of a piezo-electric, thermal bubble jet or ultrasonic atomiser. Consequently, the density or thickness of the vapour produced by the PV can be significantly reduced; this is particularly useful indoors, when the user might wish to vape very discretely. The strength of the ‘hit’ can also be decreased too, because the amount of nicotine inhaled will be reduced; this can be useful where the user wishes to reduce their nicotine consump...

case feature 3

[0266]Case or PV includes a ‘power mode’—e.g. to increase the amount of vapour produced, the user can activate a button or sensor on the case or PV, or connected app and that alters the operation of the operation of the atomising device in such a way as to increase the vapour produced—for example, it may increase the power used, or increase the frequency or duty cycle of a piezo-electric, thermal bubble jet or ultrasonic atomizer, but whilst monitoring the coil temperature to ensure that excessively high temperatures, associated with undesirable compounds in the vapour, are not reached.

[0267]Additionally, or alternatively, the system may increase the PG proportion compared to VG, if that is possible—e.g. the case or PV can mix differing proportions of PG and VG, Consequently, the density or thickness of the vapour produced by the PV can be significantly increased; the strength of the ‘hit’ can also be increased too, because the amount of nicotine inhaled will be greater.

[0268]We can...

case feature 4

Case has a PV Ejection Mechanism:

[0292]The case includes an automatic lifting mechanism (e.g. magnetic or spring-based) that, when the case is opened, gently lifts the PV up a few mm from the case to enable a user to easily grasp it and may also prevent it from falling out if tipped upside down. A mechanical lifting system could be a simple pivoting lever that contacts a part of the PV (e.g. its front face); a damped spring is placed under tension if the PV is inserted fully into the case; when the PV is released from the case (e.g. by pushing a release button), then the lever cause the PV to gently rise up by about, for example, 12 mm. A magnetic lifting mechanism could involve a permanent magnet at one part of the PV and an adjacent electro-magnet placed in the case and powered by the main battery in the case; slowly energising the electro-magnet when the PV needs to be released causes the PV to gracefully rise up out of the case.

[0293]We can generalise this feature as follows:

[02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com