Method and system for advanced diagnosis and analysis of main heating surface of boiler

A diagnostic analysis and heating surface technology, applied in the direction of boiler working status indication, computer system based on knowledge mode, intuitive inference, etc., can solve problems such as advance prediction and difficult diagnosis of heating surface faults, so as to delay accidents and facilitate deterioration Speed, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

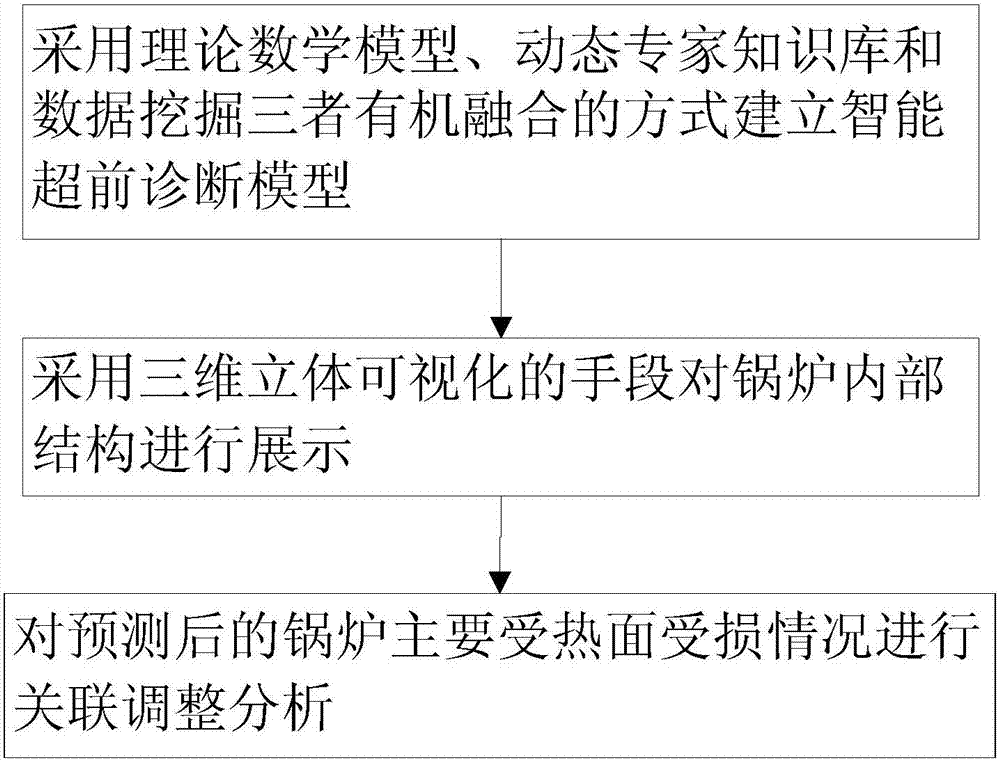

[0059] Such as figure 1 As shown in the present invention, a method for advanced diagnosis and analysis of the main heating surface of a boiler, it first adopts the organic integration of theoretical mathematical model, dynamic expert knowledge base and data mining to establish an intelligent advanced diagnosis model, and then adopts the means of three-dimensional visualization The internal structure of the boiler is displayed, and finally the predicted damage to the main heating surface of the boiler is adjusted and analyzed, and the intervention adjustment after the advanced diagnosis of the main heating surface of the boiler is carried out to form a closed-loop management, so as to avoid the occurrence of boiler failure.

Embodiment 2

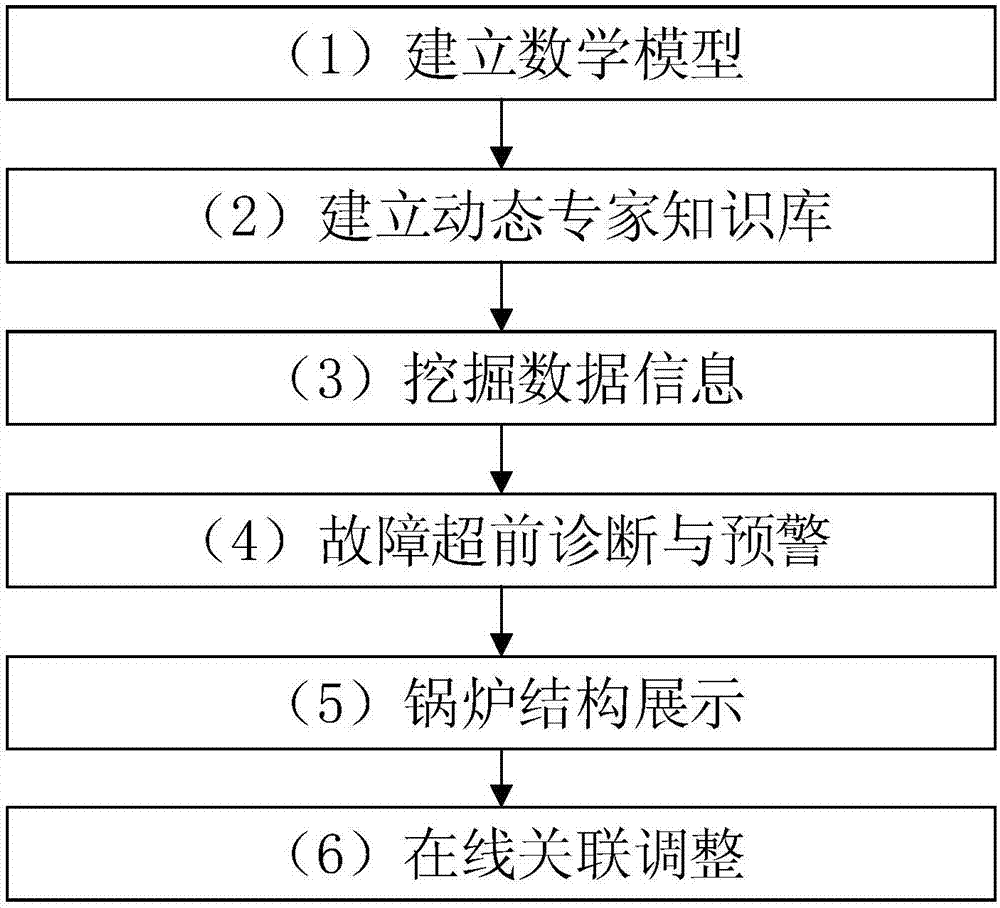

[0061] Such as figure 2 As shown, a method for advanced diagnosis and analysis of the main heating surface of a boiler of the present invention specifically comprises the following steps:

[0062] (1) Establish a mathematical model: obtain the data information of the real-time monitoring points of the boiler, establish a mathematical model of the main damage types of the heating surface of the boiler, and perform quantitative calculation and analysis of inferior damage to obtain the real-time damage of the main heating surface of the boiler;

[0063] (2) Establish a dynamic expert knowledge base: collect and organize the general theoretical knowledge for the four-tube failure of the diagnosed boiler and the historical maintenance data of the diagnosed boiler, and summarize it to obtain an expert knowledge base related to the four-tube failure of the diagnosed boiler. The expert knowledge base reserves the expert knowledge acquisition interface, constantly updates the expert k...

Embodiment 3

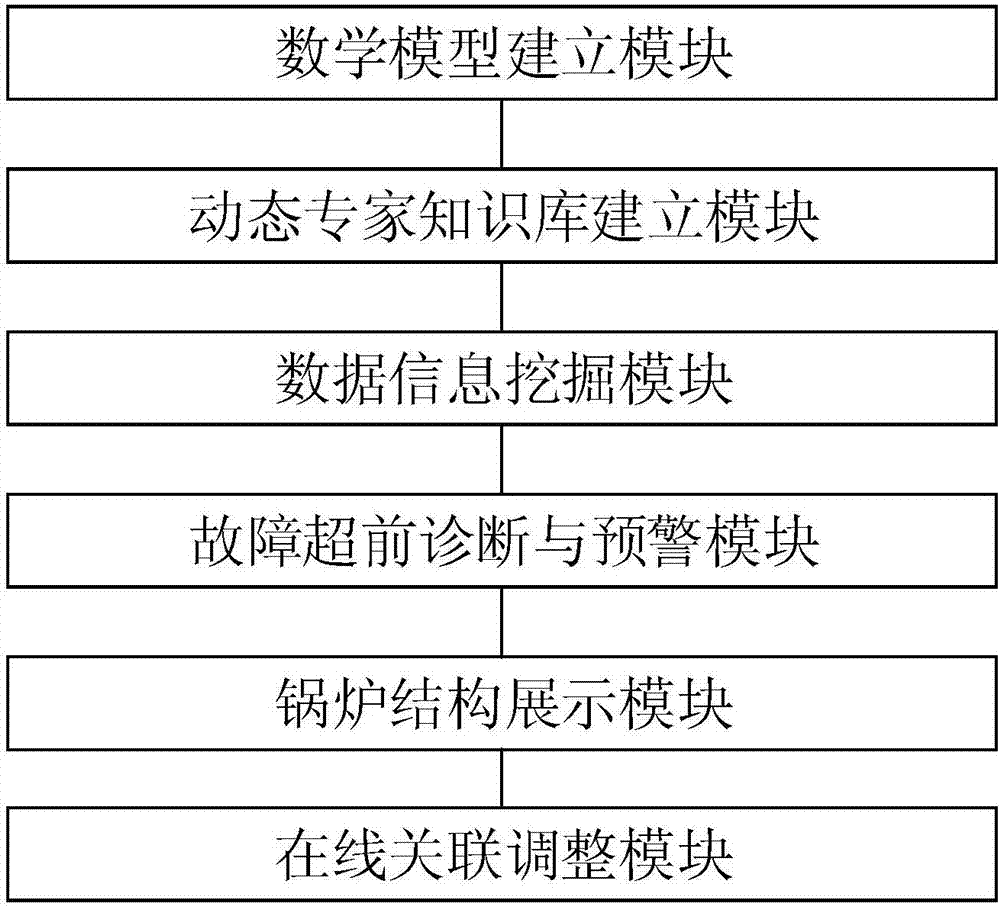

[0091] Such as image 3 Shown, a kind of boiler main heating surface advance diagnosis analysis system of the present invention, it comprises:

[0092] The mathematical model building module is used to obtain the data information of the real-time monitoring points of the boiler, establish the mathematical model of the main damage types of the boiler heating surface, perform quantitative calculation and analysis of inferior damage, and obtain the real-time damage situation of the main heating surface of the boiler;

[0093] The dynamic expert knowledge base building module is used to collect and organize the general theoretical knowledge for the four-tube failure of the diagnosed boiler and the historical maintenance data of the diagnosed boiler, and summarize to obtain the expert knowledge base related to the four-tube failure of the diagnosed boiler. The expert knowledge base reserves the expert knowledge acquisition interface, constantly updates the expert knowledge base dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com