System for combustion optimization using quantum cascade lasers

a quantum cascade laser and optimization system technology, applied in combustion control, lighting and heating apparatus, machines/engines, etc., can solve the problems of boiler tube-wall wastage, affecting the overall performance of the boiler as a whole, and failing to consider the local effects of each burner on the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Example embodiments that incorporate one or more aspects of the invention are described and illustrated in the drawings. These illustrated examples are not intended to be a limitation on the invention. For example, one or more aspects of the invention can be utilized in other embodiments and even other types of devices. Moreover, certain terminology is used herein for convenience only and is not to be taken as a limitation on the invention. Still further, in the drawings, the same reference numerals are employed for designating the same elements.

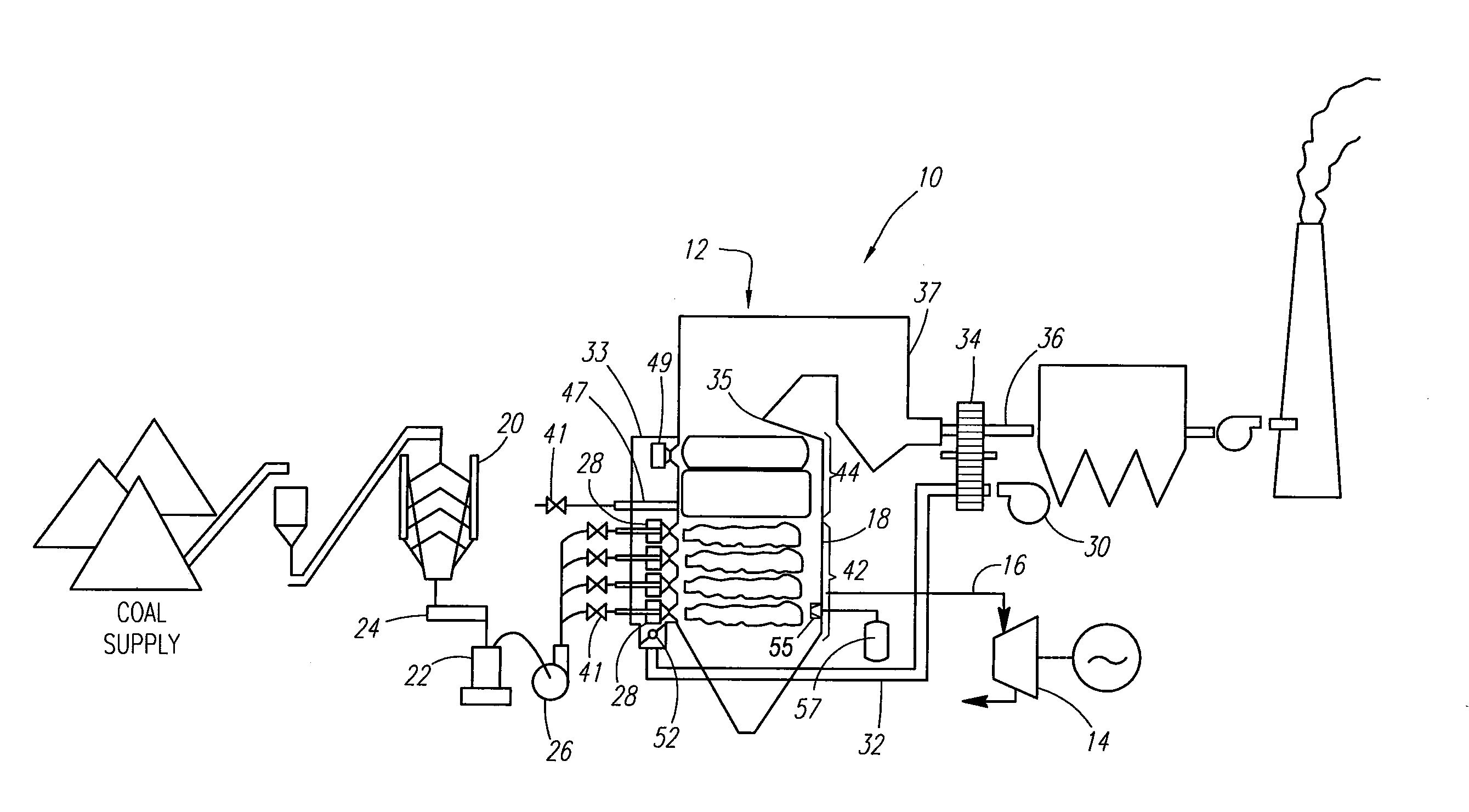

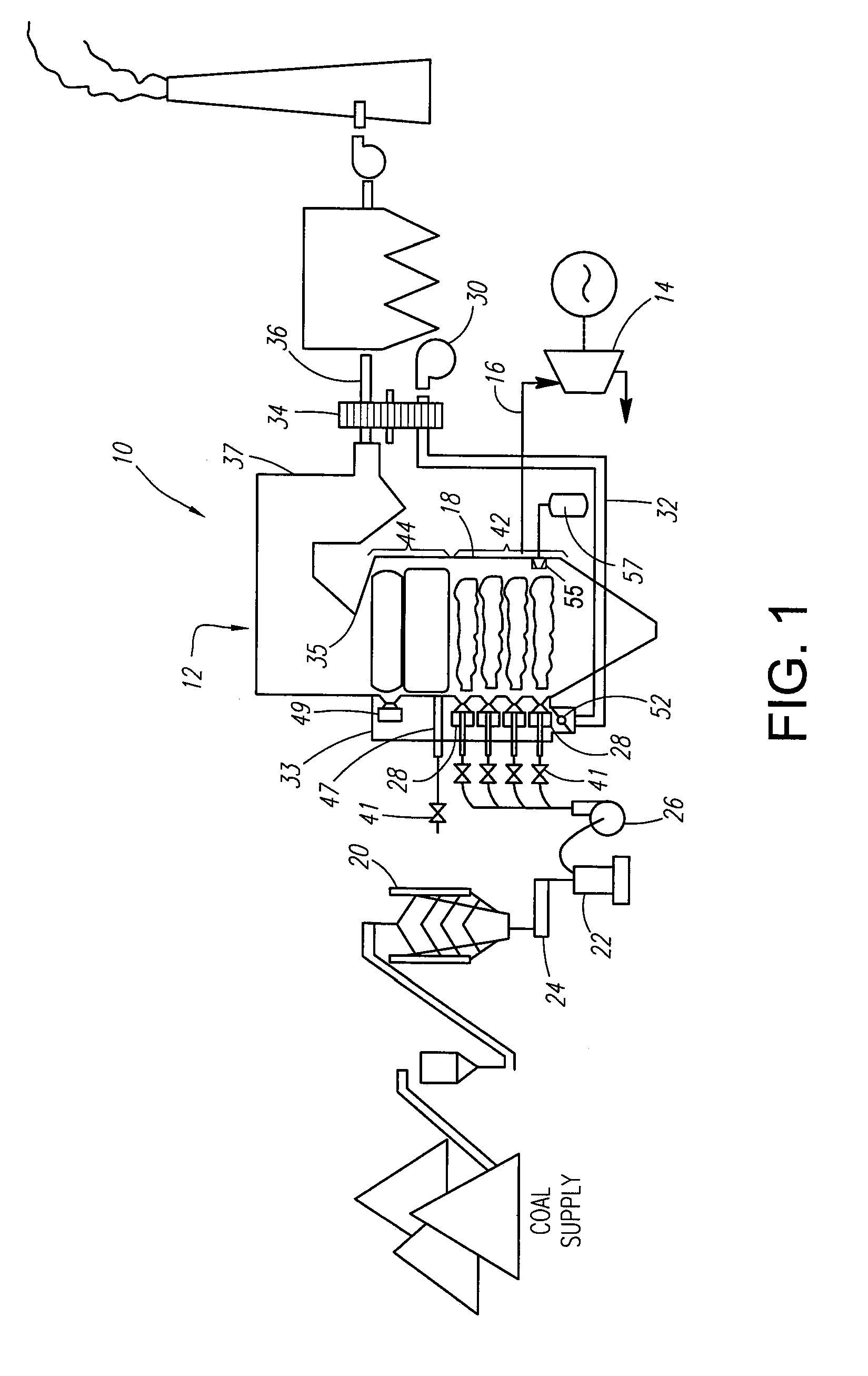

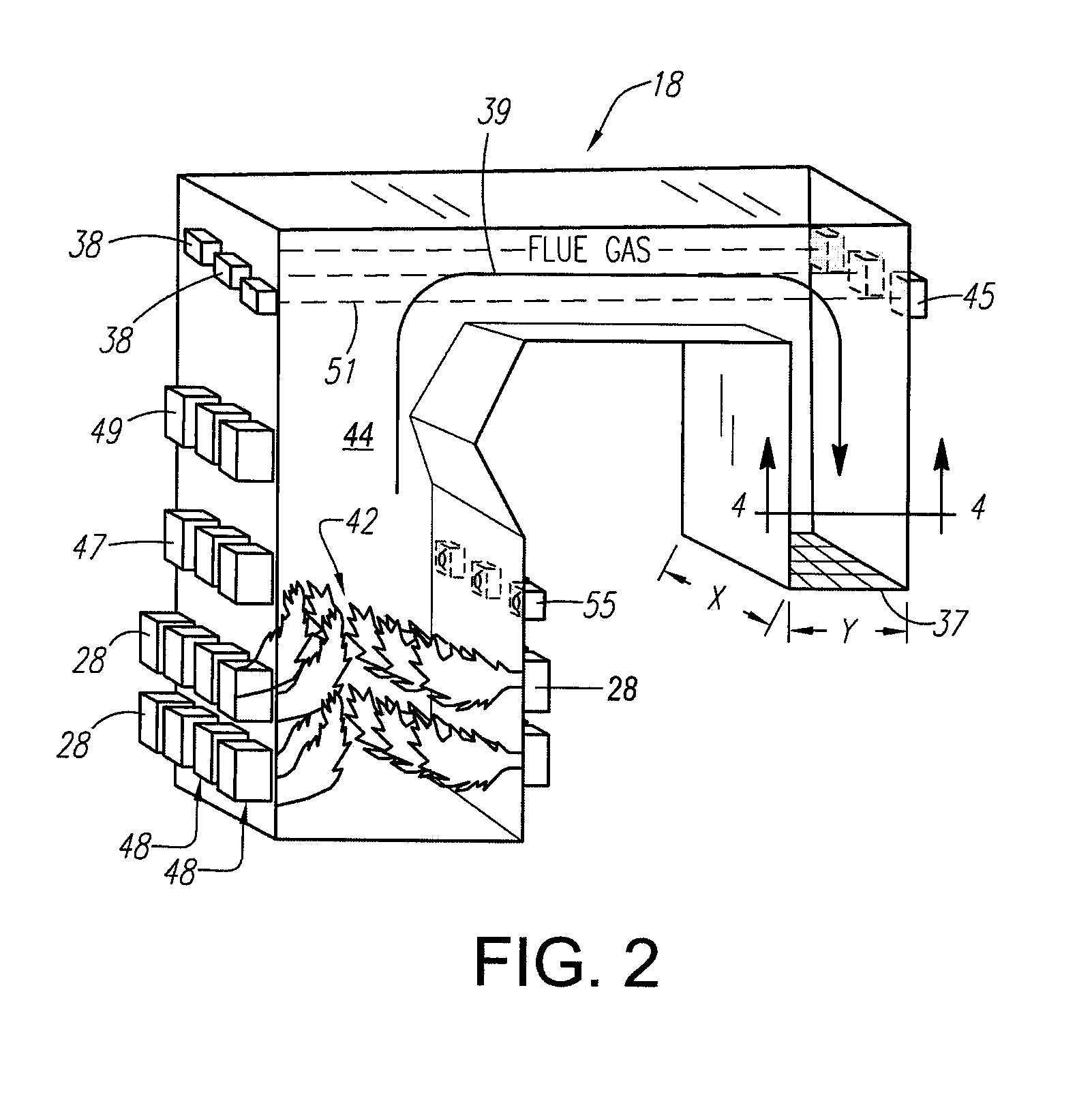

[0022]A method of optimizing operation of a fuel fired boiler is described below in detail. The method includes the use of a plurality of different sensors at different spatial locations within a fuel fired boiler furnace to track in-furnace combustion conditions and the relative differences between the performance of individual burners. Each of the sensors can be used to sense a plurality of operating conditions at the different spati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com