Method for soft measurement of smoke temperature of outlet of hearth based on real-time slagging condition of hearth

A technology of furnace exit and soft measurement, which is applied in the direction of indicating the working condition of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

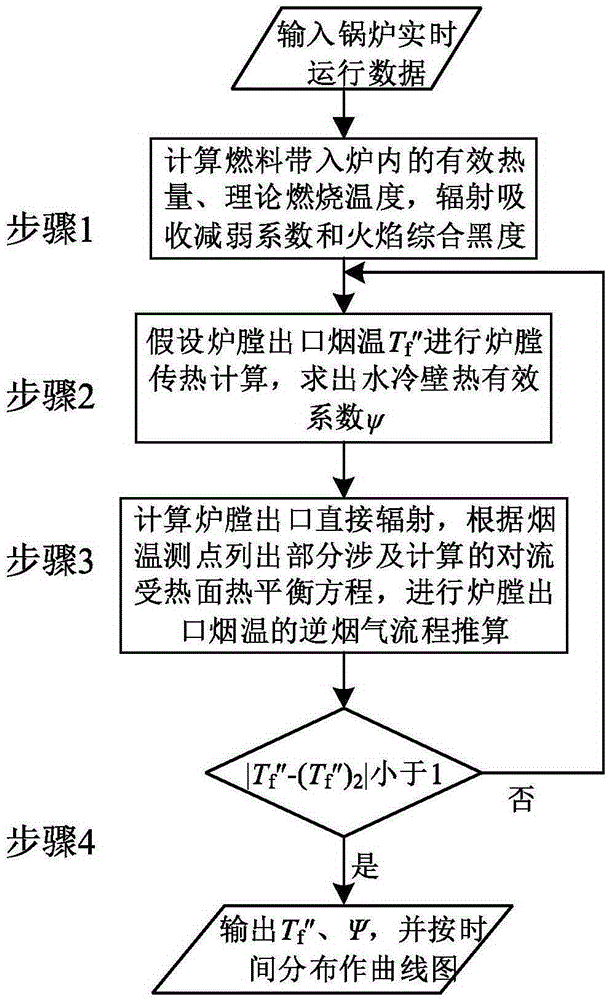

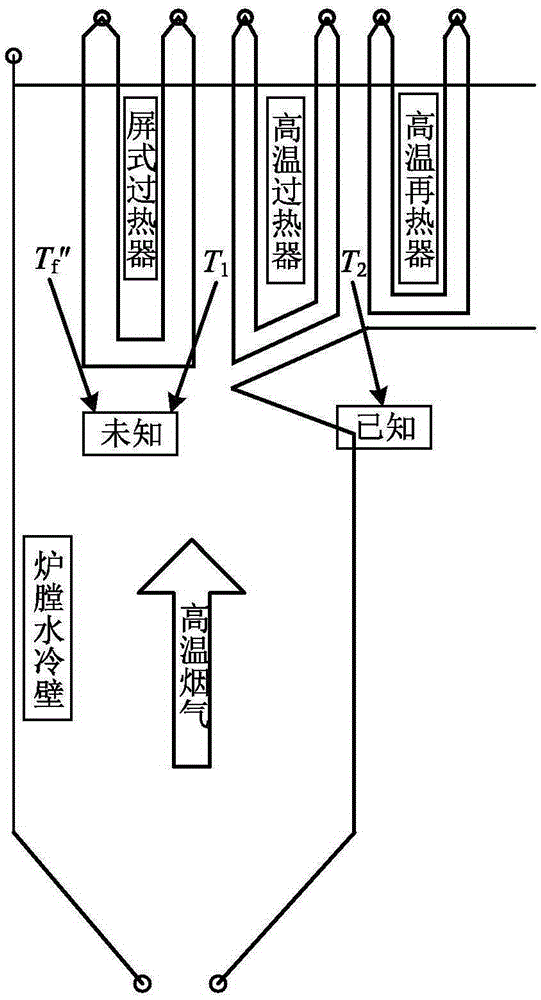

Method used

Image

Examples

Embodiment Construction

[0043] Next, according to the method of the present invention, a boiler is selected for example calculation, so as to further illustrate the specific implementation of the present invention.

[0044] The boiler selected for the calculation of the example is a 600MW supercritical once-through boiler, the boiler model is HG-1956 / 25.4-YM5, which is a once-through boiler with intermediate reheating, supercritical pressure variable pressure operation and a built-in recirculation pump starting system. This boiler adopts Π-shaped layout, single furnace, balanced ventilation, solid slag discharge, swirl burner with front and rear wall layout, and opposite combustion. The boiler takes the maximum continuous output condition (BMCR) as the design parameter, and can carry the rated load (BRL) for a long time. The main design parameters are shown in Table 1.

[0045] Table 1 Main Design Parameters of Boiler

[0046]

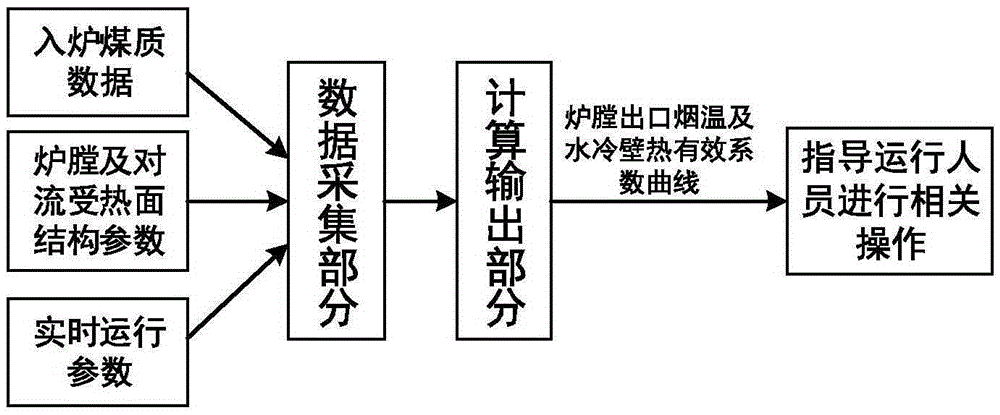

[0047] The data acquisition part includes the coal quality data of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com