Coal-fired boiler interactive online monitoring method

A coal-fired boiler, interactive technology, applied in the direction of boiler working status indication, control system, steam generation, etc., can solve problems such as inability to effectively grasp the boiler running status, invisible, etc., to achieve human-machine dialogue function, optimization running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

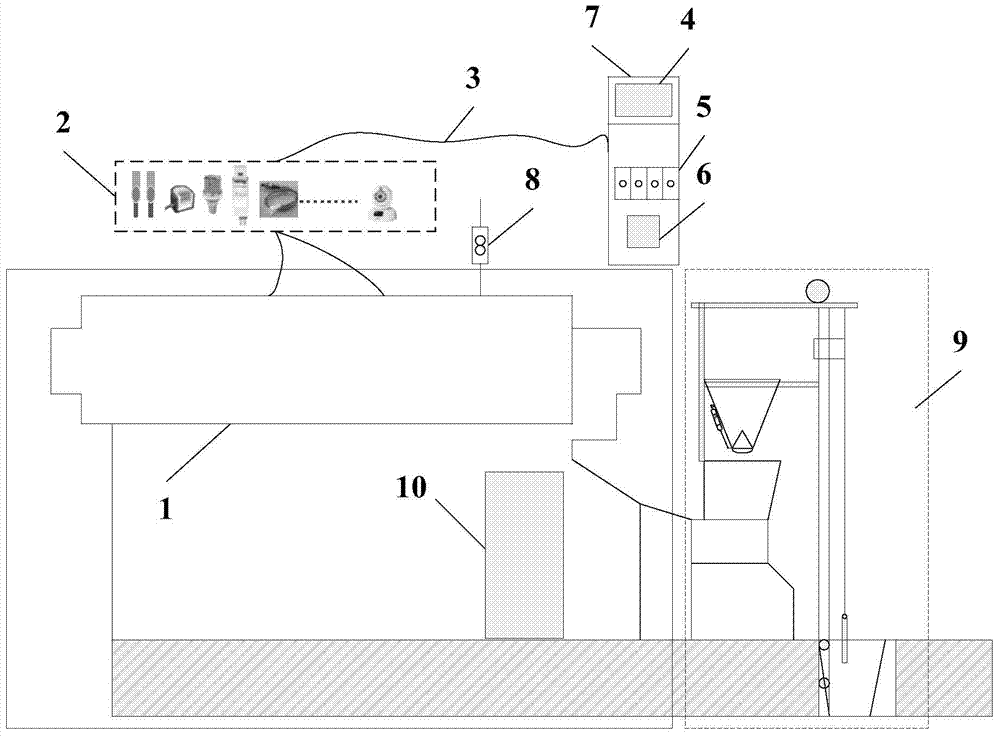

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] As shown in the figure, the interactive online monitoring method for coal-fired boilers, the method steps are as follows:

[0021] (1) First of all, various sensors 2, feed water flowmeter 8 and coal-fired metering device 9 are installed on the boiler body 1 on site to realize reliable collection of boiler operating parameters; the collected signals are divided into variable signals that need to be installed with sensors, including : Feed water hardness, steam pressure, steam temperature, feed water temperature, ambient temperature, exhaust gas temperature, exhaust gas oxygen content, feed water flow rate and coal consumption; and status signals received from the boiler operation control cabinet 10, including: blower start Stop, current, voltage, high water level, low water level and comprehensive alarm;

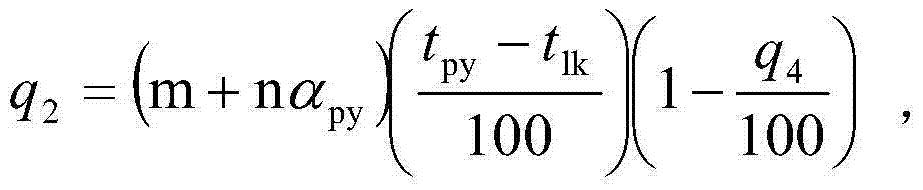

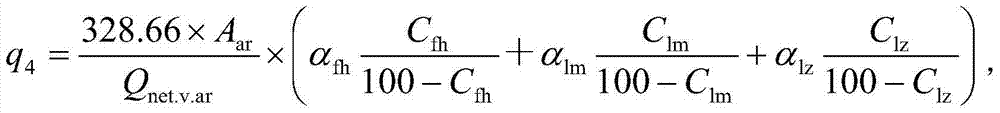

[0022] (2), the collected signal data i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com