Asynchronous magnetic couplings for high temperature resistant high performance oblique slot type rotor

A magnetic coupling, high-performance technology, applied in the direction of permanent magnet clutch/brake, etc., can solve the problems of increased rotor loss, reduced efficiency, and small distribution difference, etc., to achieve increased transmission torque, stable and reliable operation, The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

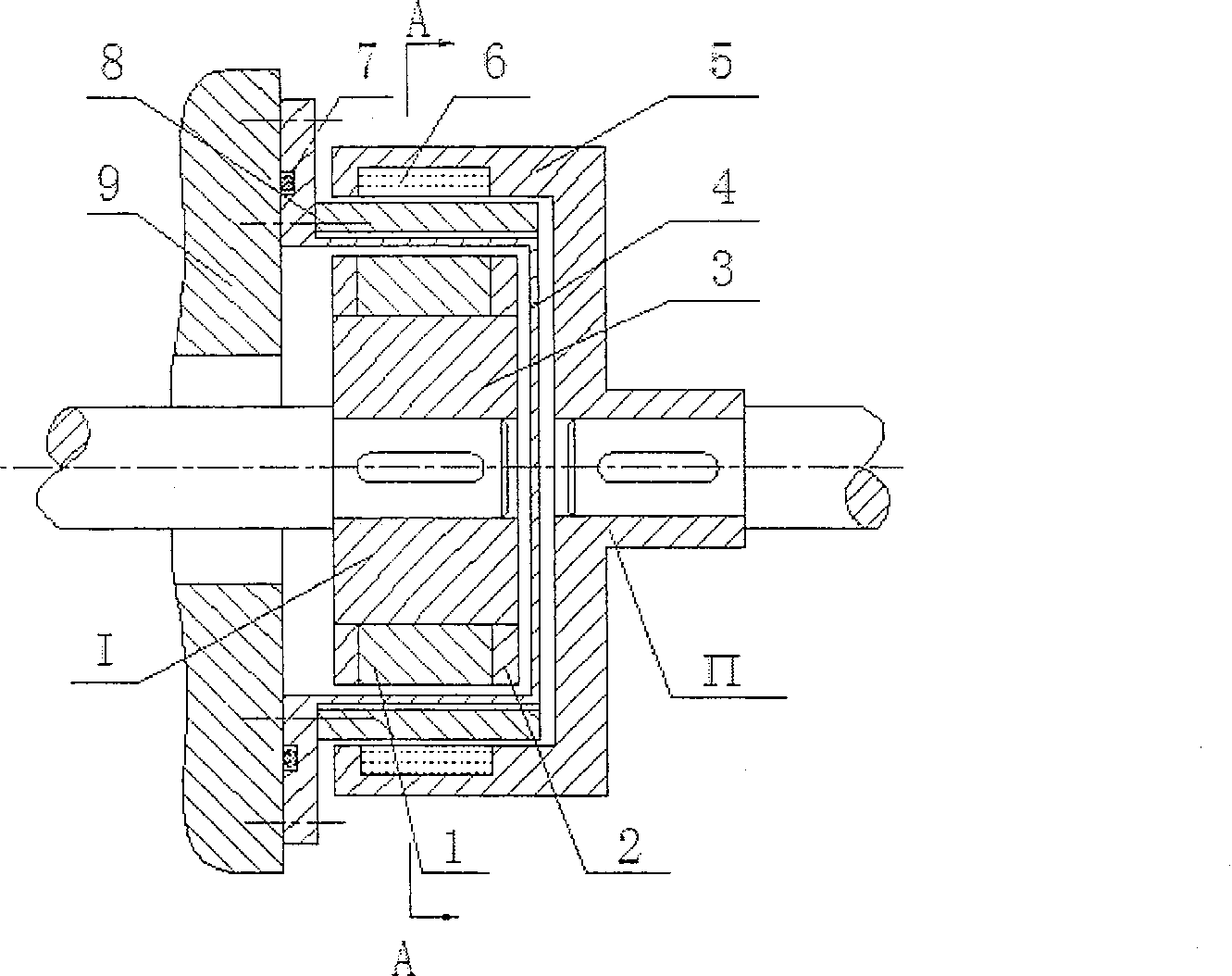

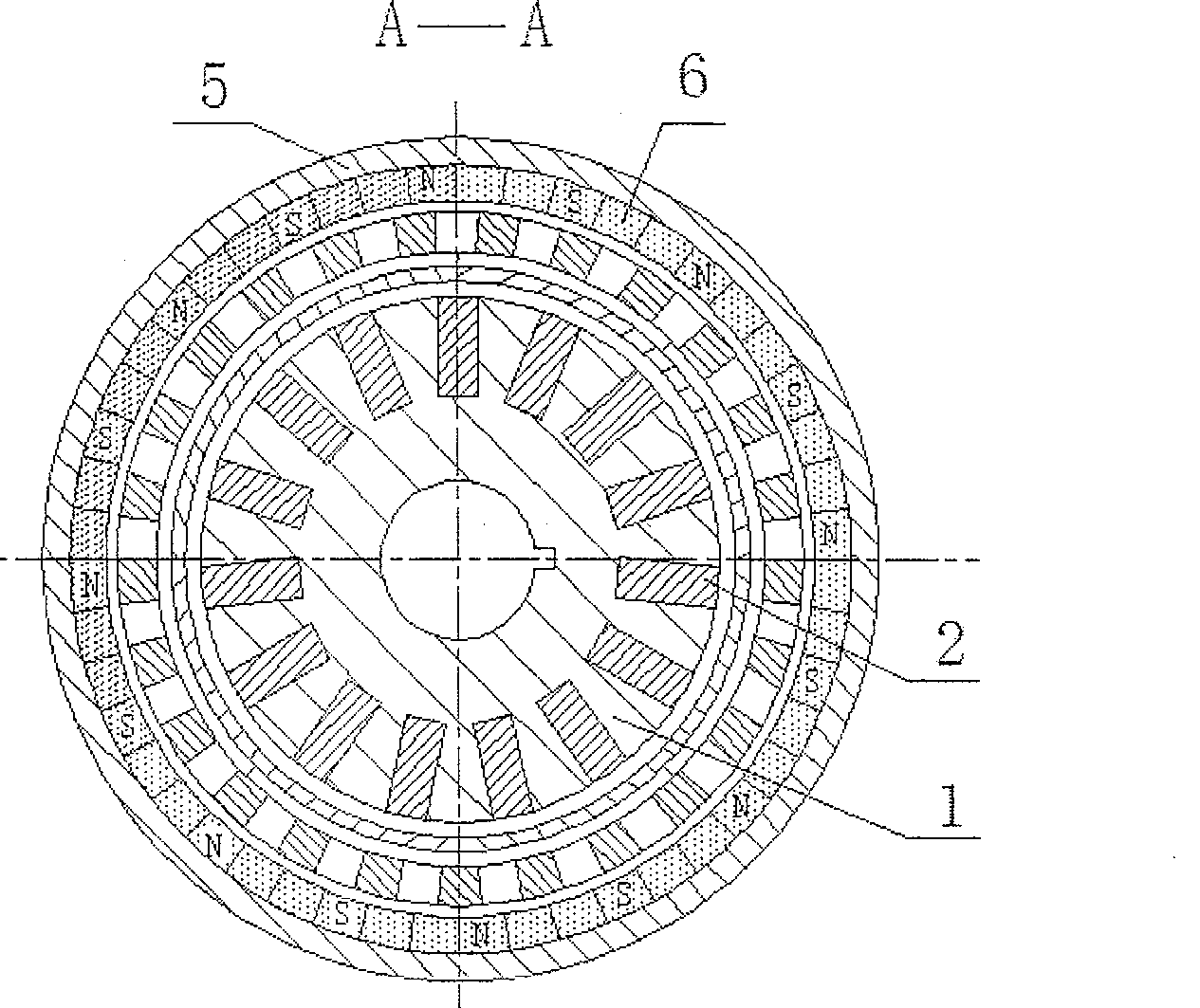

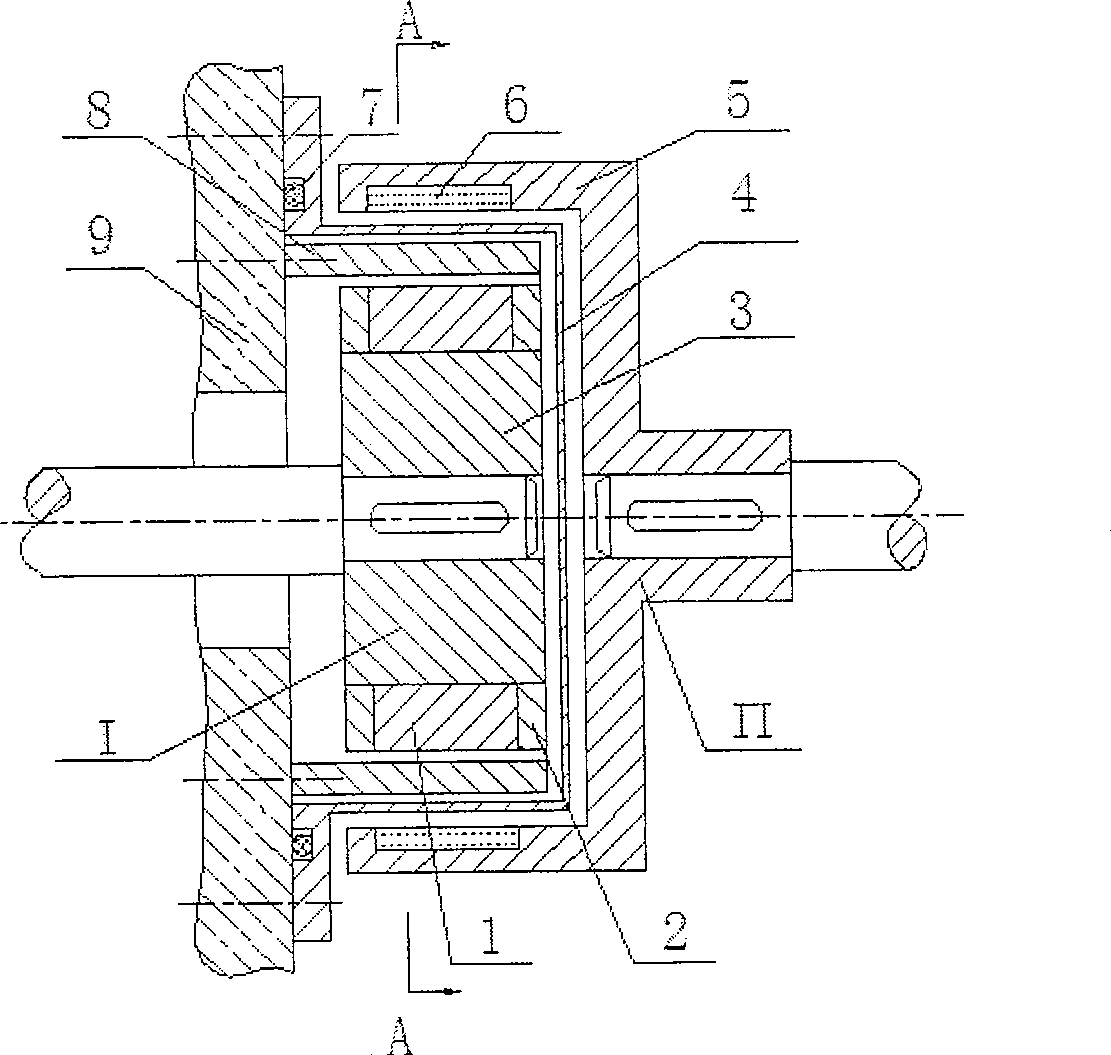

[0027] The overall structure of the present invention is as figure 1 As shown, the device includes: an outer rotor composed of an outer rotor base body 5 and an outer rotor permanent magnet 6, an inner rotor composed of an inner rotor base body 3, a magnetic induction conductor and an end ring 2, a sealed spacer sleeve 4 and a toothed magnetic pole slice 8. The sealing spacer 4 is placed between the inner rotor and the outer rotor, and the cover is installed on the inner rotor. The toothed magnetic pole piece 8 is placed between the inner rotor and the outer rotor, and fixed on the body 9 with screws. There are two ways to place it: one is to place it tightly outside the sealing spacer 4 and close to the outer rotor base 5, The other is placed in the sealing spacer 4 and close to the inner rotor base 3 . The outer rotor is composed of an outer rotor base body 5 and an outer rotor permanent magnet 6. The outer rotor permanent magnets 6 are closely arranged in an even number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com