Permanent magnetic speed regulation, brake or load apparatus capable of stepless adjustment of magnetic field intensity

A technology of magnetic field strength and stepless adjustment, applied in the direction of permanent magnet clutch/brake, asynchronous induction clutch/brake, etc. Process difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

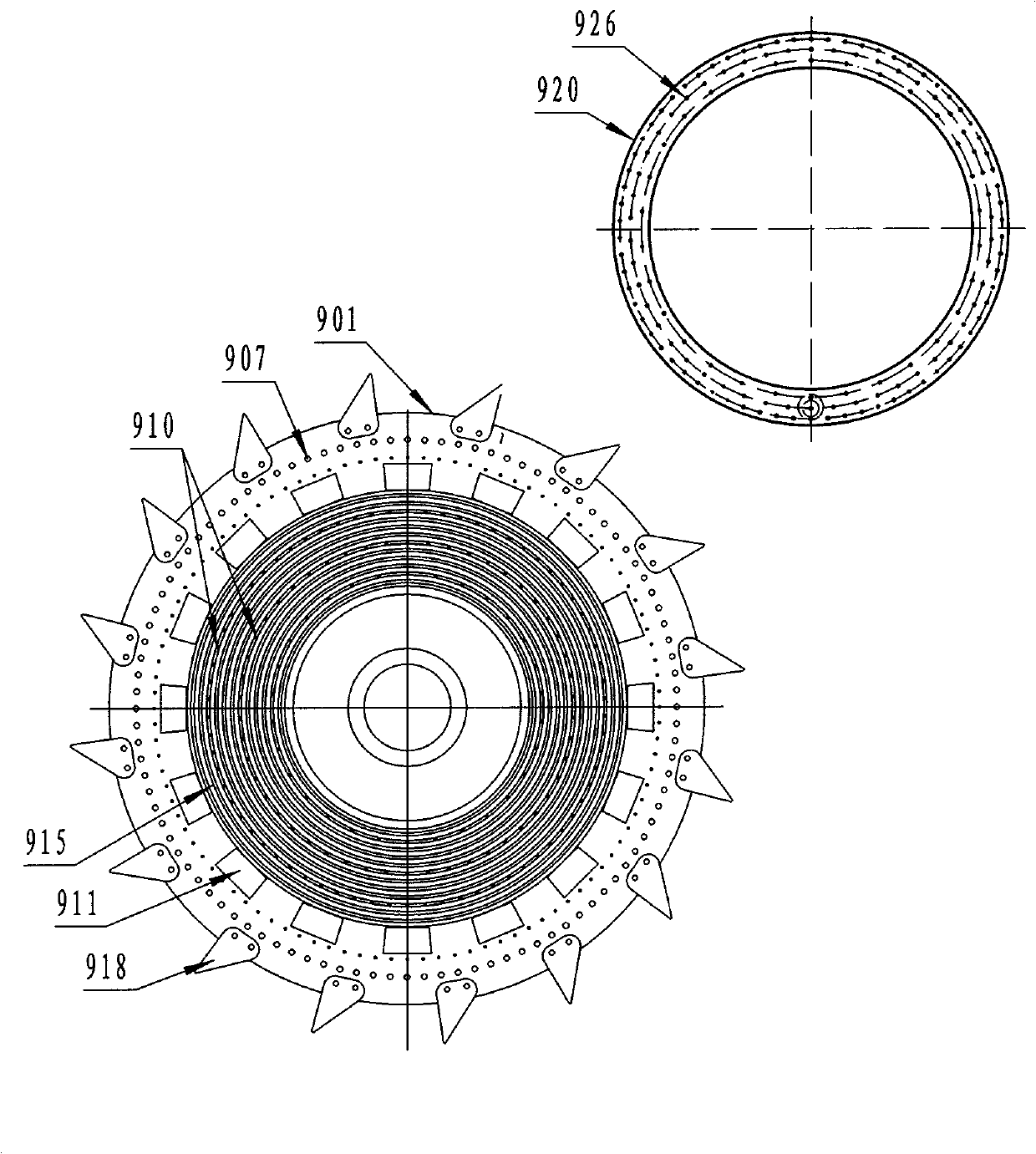

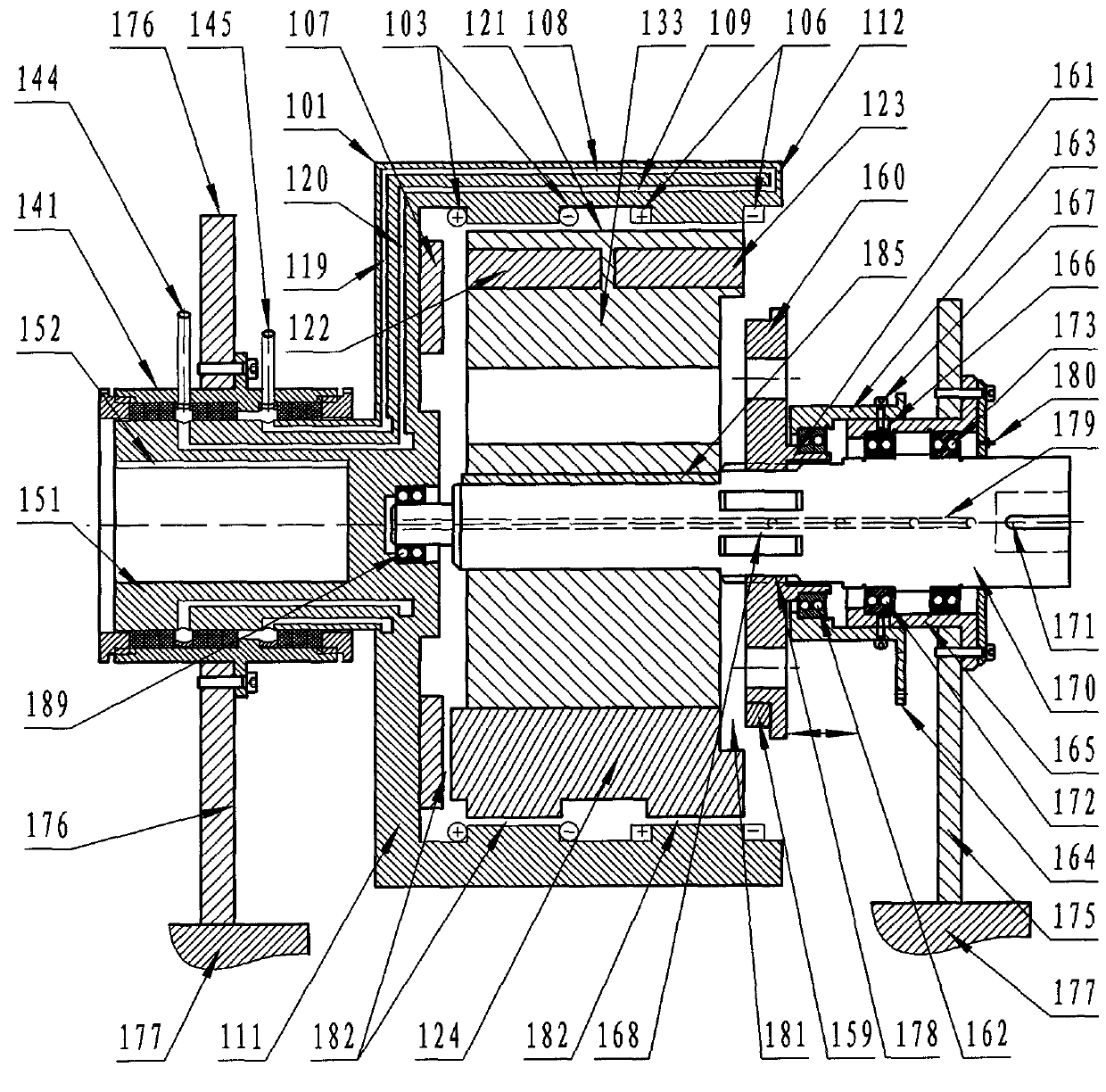

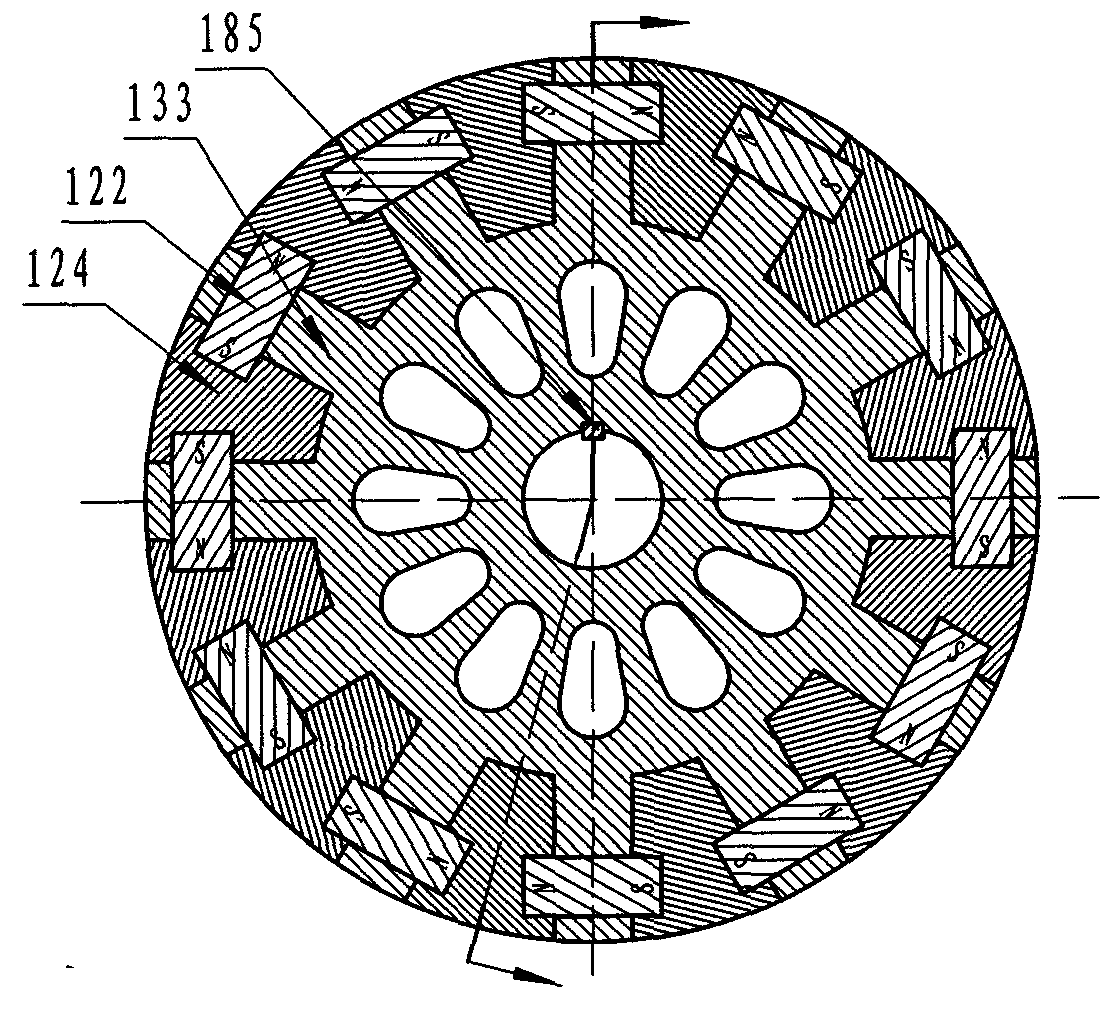

[0070] Such as figure 1 , 2 As shown in and 3, it is a turntable and drum combined permanent magnetic coupling coupling composed of "1 set of axial magnetic field + 2 sets of radial magnetic field" single-layer permanent magnetic coupling components on both sides, mainly composed of active rotor (101), passive Rotor (121), three working magnetic coupling air gaps (182), magnetic leakage magnetic circuit / air gap (181), magnetic leakage magnetic circuit air gap adjustment discs (160, 159) and transmission adjustment mechanism (170, 168, 178 , 161, 162, 163, 167, 165, 166, 172, 173, 164) form. The specific settings include: a set of axial magnetic field permanent magnetic coupling components (the axial magnetic field annular metal conductor disk 107 is coupled with the yoke 124 of the permanent disks 122 and 123) and two sets of radial magnetic field permanent magnetic coupling components in series (radial magnetic field cylindrical armature winding disk 103 is coupled with the...

Embodiment 2

[0074] Such as Figure 4 , 5 , 6, it is "2 sets of radial magnetic field + 1 set of radial magnetic field" two-layer three-sided permanent magnetic coupling assembly nested turntable drum combination type permanent magnetic coupling coupling, mainly composed of active rotor (201), passive Rotor (221), three working magnetic coupling air gaps (282), magnetic leakage magnetic circuit / air gap (281), magnetic leakage magnetic circuit air gap adjustment discs (260, 259) and transmission adjustment mechanism (270, 255, 256 , 257, 258, 254, 261, 262, 263, 264, 265, 266, 297, 298). The specific setting includes: a group of axial magnetic field permanent magnetic coupling components (the axial magnetic field annular metal conductor disc 207 is coupled with the yoke 224 of the permanent disk 223) and two groups of radial magnetic field permanent magnetic coupling components (radial The magnetic field cylindrical metal conductor disk 203 is coupled with the yoke 224 of the permanent ma...

Embodiment 3

[0077] Such as Figure 7As shown, it is a "3 sets of radial magnetic field + 1 set of axial magnetic field" two-layer three-sided permanent magnetic coupling assembly nested turntable and drum combined permanent magnetic coupling coupling, mainly composed of active rotor (301), passive rotor ( 321), three working magnetic coupling air gaps (382), flux leakage magnetic circuit / air gap (381), petal-shaped magnetic flux leakage magnetic circuit air gap adjustment disc (adjustment disc body 360, permanent magnet group 359) and transmission adjustment mechanism (370, 355, 357, 356, 358, 354, 361, 362, 363). There are two aspects different from Embodiment 2, one is that the permanent magnets (322, 323) are combined, and the two permanent magnets are spliced or bonded together with N-S or S-N, that is, a group of axial magnetic field permanent magnetic coupling Components (the axial magnetic field circular metal conductor disk 307 is coupled with the yoke 324 of the permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com