Transmission shaft permanent magnet coupling drive and speed regulation device capable of adjusting magnetic torque

A permanent magnetic coupling and speed regulating device technology, applied in the direction of permanent magnetic clutch/brake, electromechanical device, electric brake/clutch, etc., can solve the problem that the power capacity cannot be too large, the magnetic torque power is small, and high reliability cannot be adapted And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

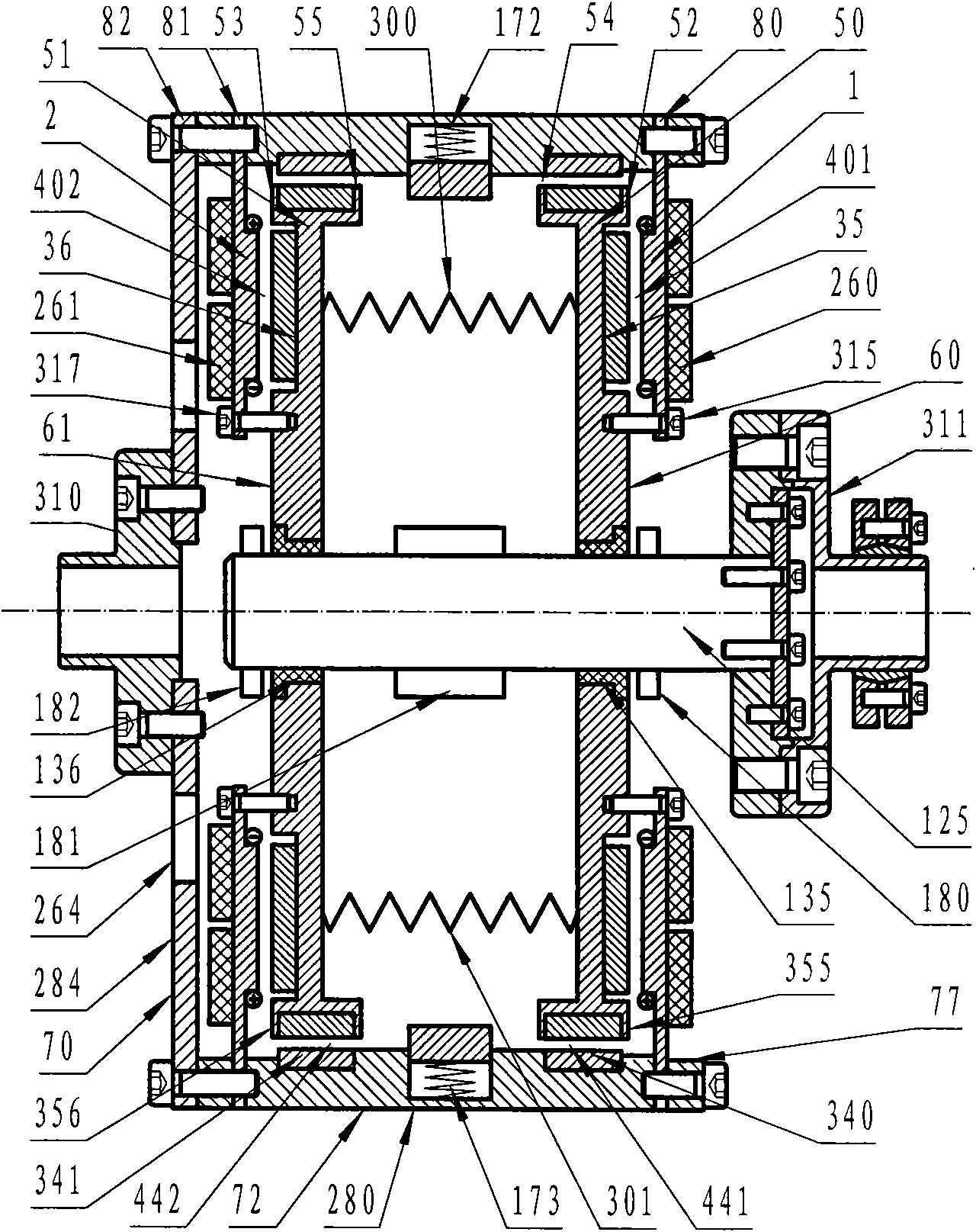

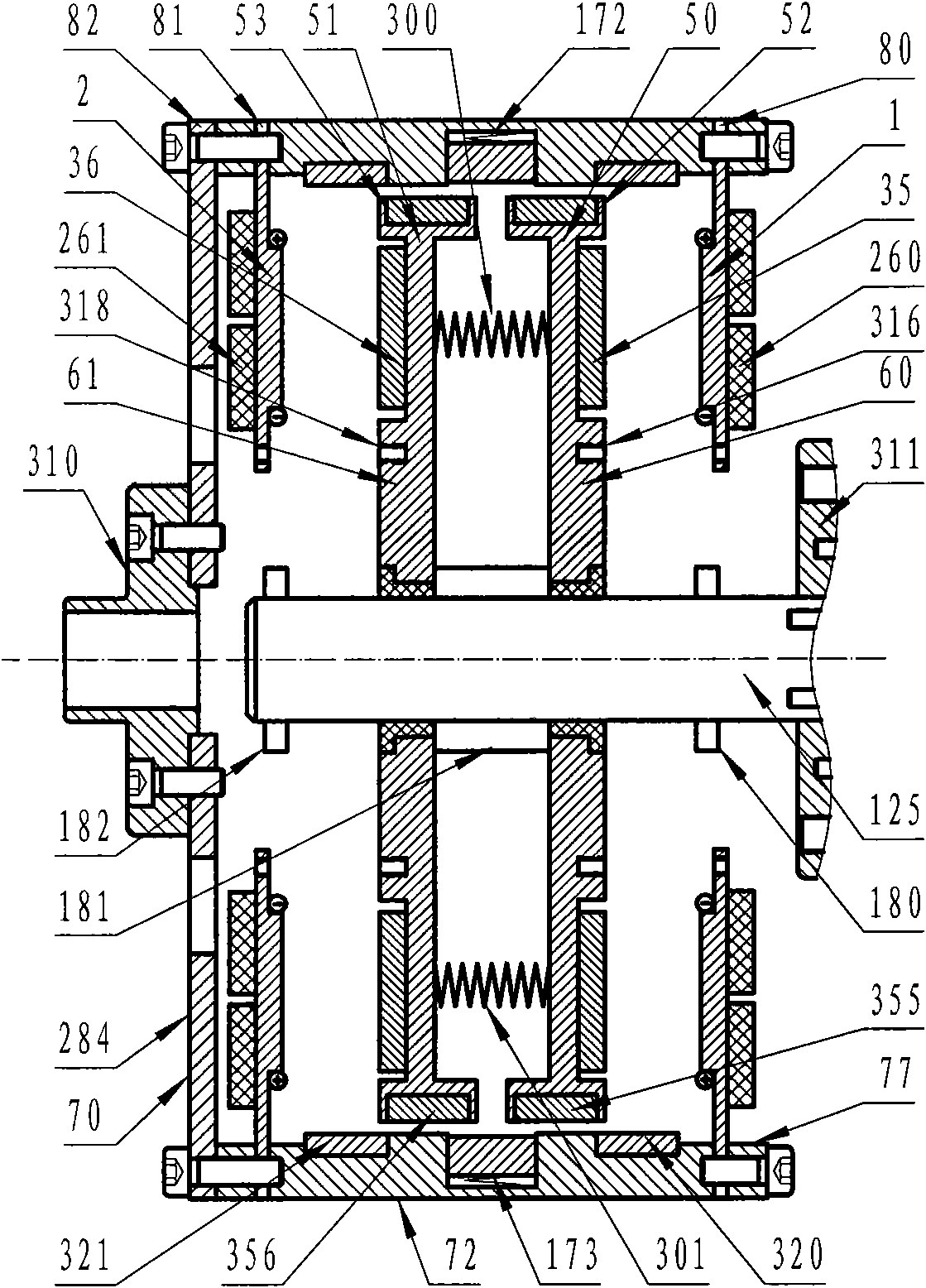

[0050] Such as figure 1 , figure 2 with image 3 As shown, it is a permanent magnetic coupling device of a drum type structure composed of two inner drums (50, 51) and an outer drum (70). The end walls (80, 81) of the outer drum are respectively provided with axial magnetic field armature winding disks (1, 2), and the end walls (60, 61) of the inner drum are respectively provided with axial magnetic field permanent magnet disks ( 35, 36), they are correspondingly coupled to form two axial magnetic field armature winding permanent magnetic coupling assemblies (401, 402), and the inner circumferential surface (77) of the outer drum wall (72) is provided with a radial magnetic field armature winding The discs (320, 321), the outer circumferential surfaces (54, 55) of the inner drum walls (52, 53) are provided with corresponding radial magnetic field permanent magnet discs (355, 356), and are respectively coupled to form two radial magnetic discs. The magnetic field metal cond...

Embodiment 2

[0054] Such as Figure 4 with Figure 5As shown, it is a permanent magnetic coupling device of a rotating drum structure composed of two inner rotating drums (550, 551) and an outer rotating drum (570). The end walls (580, 581) of the outer drum are respectively equipped with axial magnetic field grate type armature discs (510, 511), and the end walls (560, 561) of the inner drum are respectively equipped with axial magnetic permanent magnets. Discs (535, 536), which are respectively coupled to form two axial magnetic field grate type armature permanent magnetic coupling assemblies, and the inner peripheral surface (577) of the outer drum wall (572) is provided with a radial magnetic field permanent magnet disc ( 850,851), the outer circumferential surface (554,555) of the inner drum wall (552,553) radial magnetic field permanent magnet discs (855,856), and respectively correspondingly coupled to form a radial magnetic field double permanent magnetic coupling assembly; The g...

Embodiment 3

[0057] Such as Image 6 with Figure 7 As shown, it consists of axial magnetic field armature winding disks (1001, 1002) and axial magnetic field permanent magnet disks (1035, 1036) respectively coupled to form axial magnetic field armature winding permanent magnetic coupling assemblies (1001 and 1035, 1002 and 1036) A permanent magnetic coupling device with a turntable structure arranged back to back; the active permanent magnetic coupling turntable coupling mechanism is composed of a cage wall (1280) and a cage end wall (1284), and the cage end wall (1284) is connected to the drive shaft The couplings (1310) are connected; the passive permanent magnetic coupling turntable coupling mechanism consists of the turntable end wall (1060, 1061), the rolling screw auxiliary nut (1154, 1155) on the turntable end wall, the rolling screw auxiliary screw ( 1152, 1153), the slide bar hole on the end wall (1060, 1061) of the turntable not shown in the figure and its shaft sleeve and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com