Permanent magnet coupling device for cylindrical transmission shaft

A technology of permanent magnet coupling and transmission shaft, applied in the field of load speed regulation system and motor driving, it can solve the problems of low heat dissipation efficiency, insufficient processing, and too large power capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

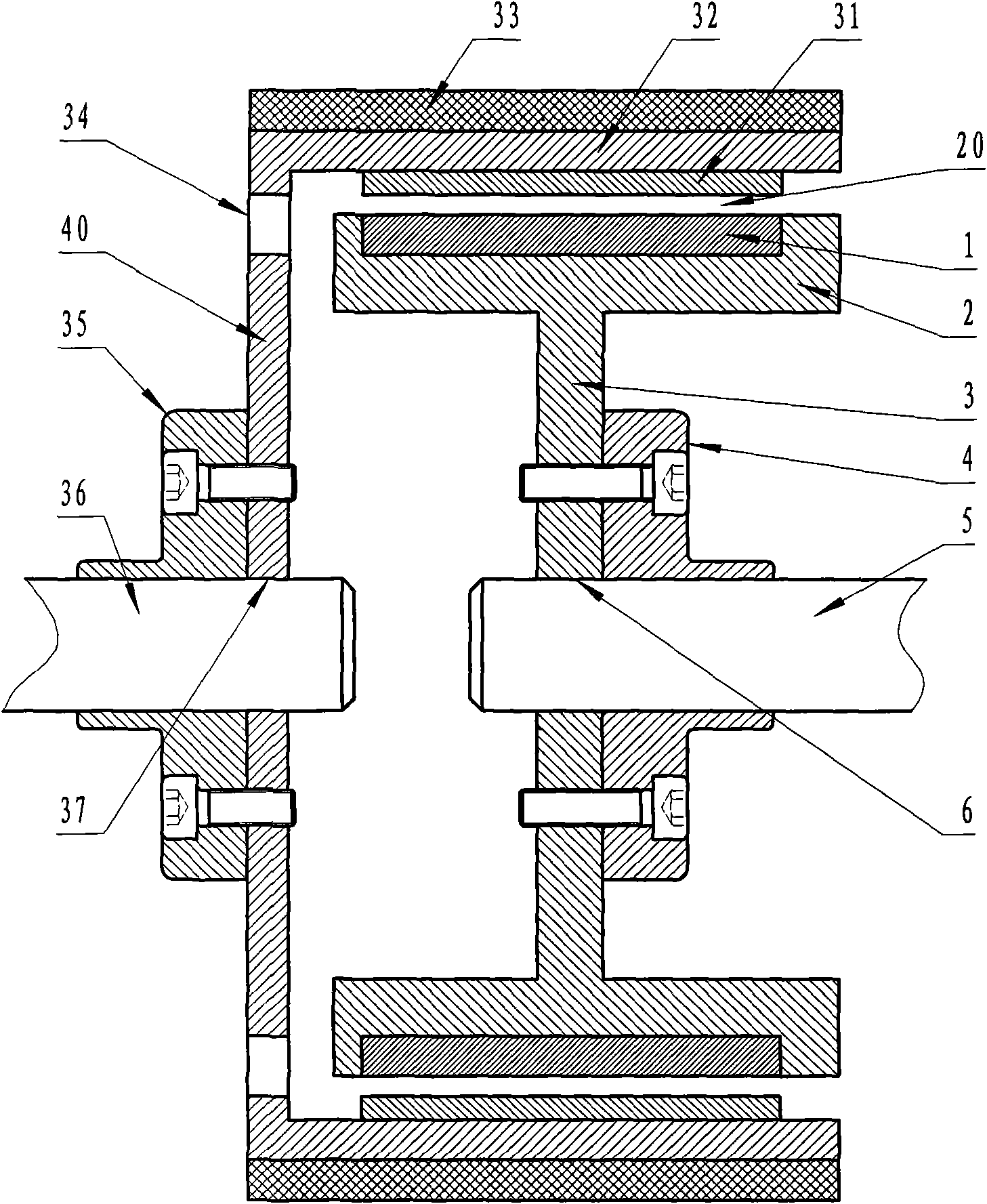

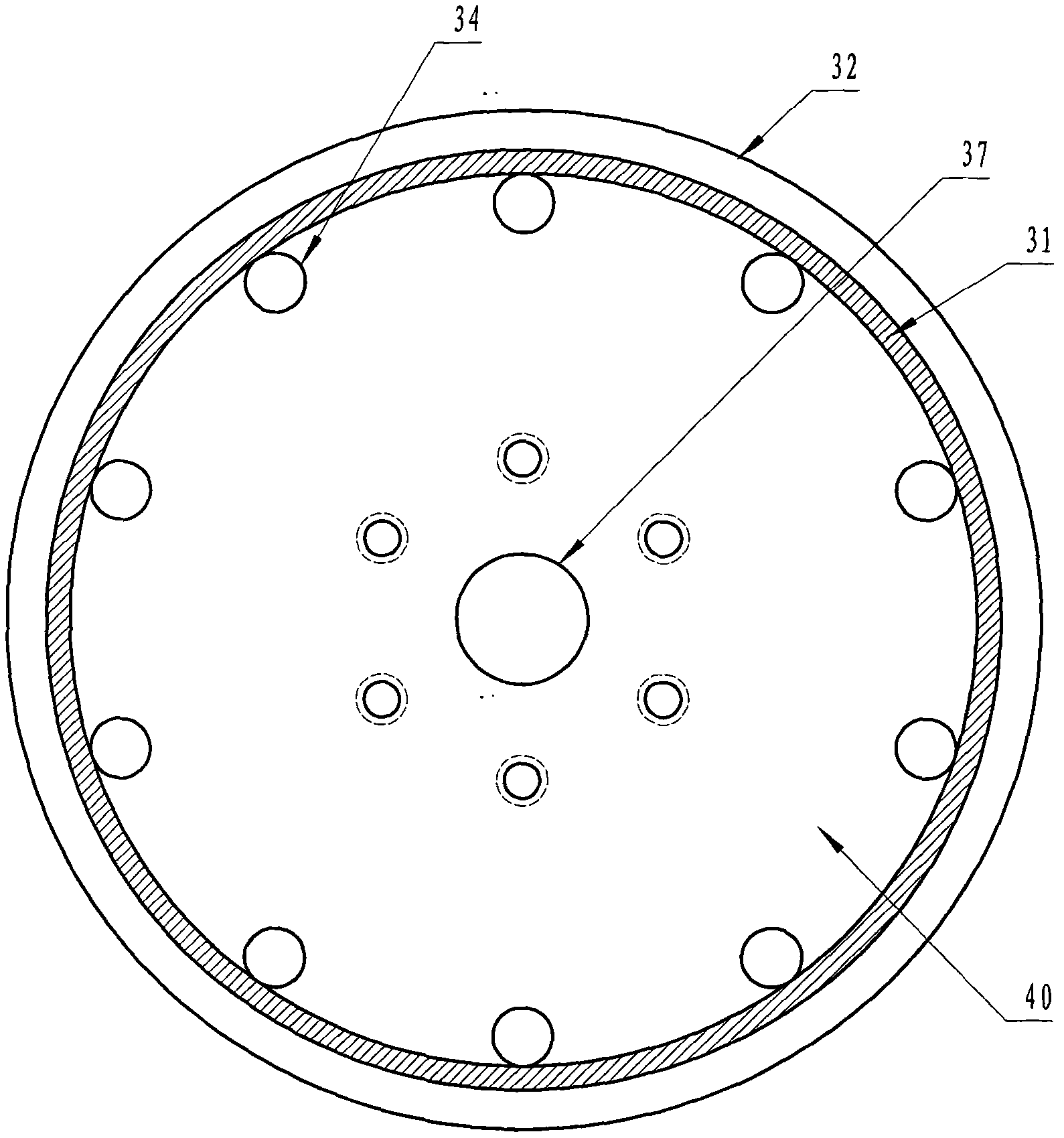

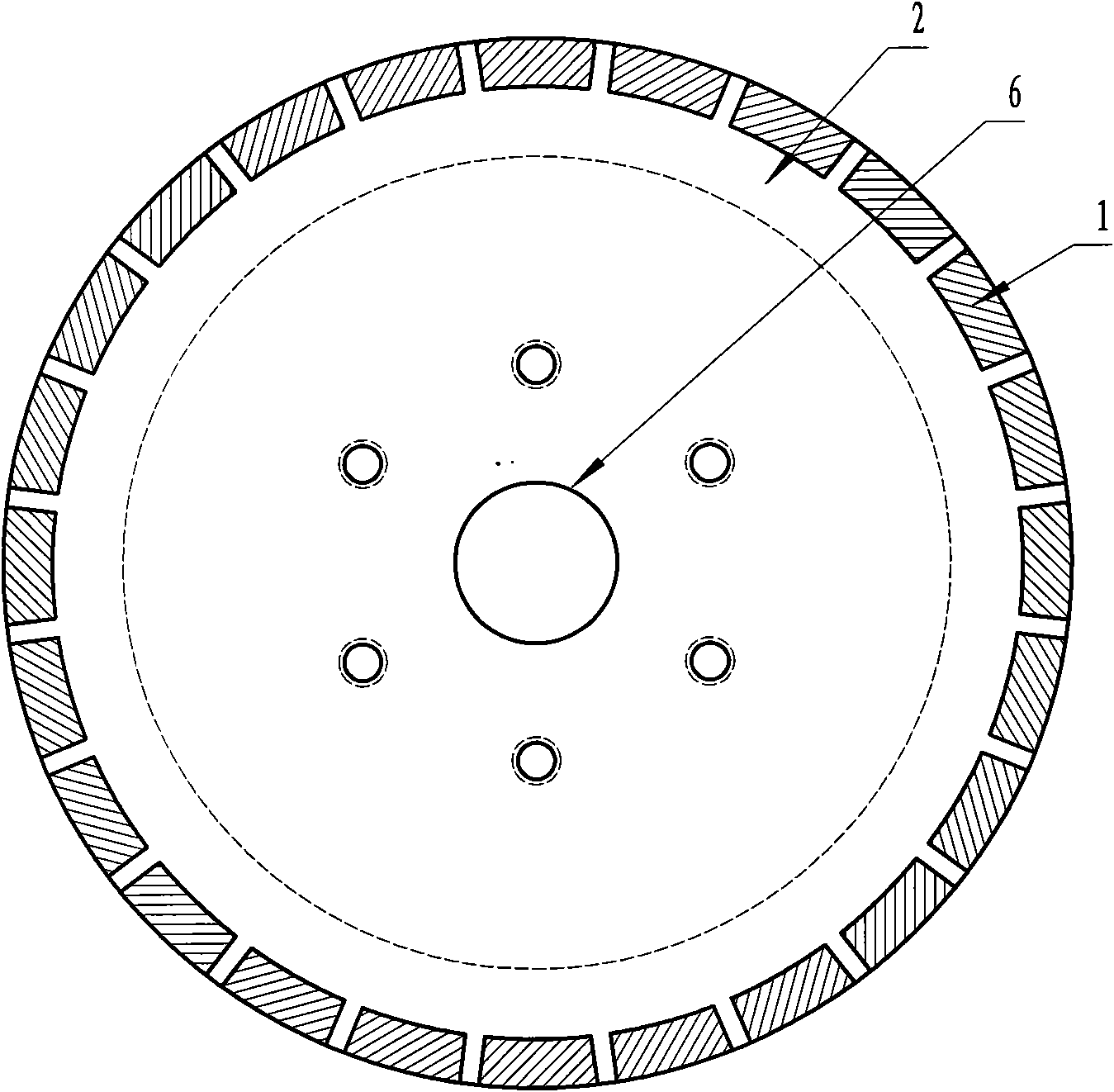

[0062] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, it consists of a group of two cylindrical outer rotor cylinders (31, 32 and 33) and inner rotor cylinders (1 and 2) coupled with radial permanent air gap magnetic fields (20) nested in each other. Components, a pair of outer rotor cylinder shaft coupling mechanisms (32, 40) in a cylindrical direct connection structure composed of the outer rotor cylinder wall (32), the outer rotor cylinder end wall (40) and the shaft hole (37) provided thereon and 37), a pair of inner rotor barrel coupling mechanism (2, 3 and 6), and the corresponding input coupling (35) and output coupling (4); wherein the inner side of the outer rotor cylinder wall (32) serves as the radial magnetic field of the radial magnetic field conductor cylinder (31) The conductor mounting plate (32) is used, and a section of cylindrical radial magnetic field conductor cylinder (31) is fixedly attached to the inner side of the radial magnetic fi...

Embodiment 2

[0066] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it consists of a set of two cylindrical outer rotor cylinders (131 and 132) and inner rotor cylinders (101 and 102) coupled with radial permanent air gap magnetic fields (120) nested in each other, a pair of The outer rotor cylinder coupling mechanism (132, 140 and 137) of the cylindrical direct connection structure composed of the outer rotor cylinder wall (132), the outer rotor cylinder end wall (140) and the shaft hole (137) provided thereon, A pair of inner rotor barrel coupling mechanisms (102, 103 and 106) with a direct connection structure consisting of the inner rotor barrel wall (102), the inner rotor barrel end wall (103) and the shaft hole (106) provided thereon, and the corresponding input coupling (135) and output coupling (104); wherein the inner side of the outer rotor cylinder wall (132) serves as the radial magnetic field of two radial magnetic field squirrel-cage armature...

Embodiment 3

[0069] Such as Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14As shown, it consists of a group of two cylindrical mutually nested radial permanent air gap magnetic fields (220) and an outer rotor cylinder (231 and 232, 218 and 218) coupled with an axial permanent air gap magnetic field (221) 232, 239 and 240, 233) and inner rotor barrel (201 and 202, 212 and 202, 213 and 217) assembly, a pair of outer rotor barrel wall (232) and outer rotor barrel end wall (240) and its upper The outer rotor cylinder shaft coupling mechanism (232, 240 and 237) of the cylindrical direct coupling structure composed of the provided shaft hole (237), a pair of inner rotor cylinder wall (202) and inner rotor cylinder end wall (203 and 208 ) and the inner rotor tube coupling mechanism (202, 203 and 206, 202, 208 and 207, 250) composed of the shaft holes (206 and 207) and the non-circular central short shaft (251), respectively, and the corresponding The input coupling (235) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com