Magnetic coupling

A magnetic coupling and magnetic pole technology, applied in the direction of permanent magnetic clutch/brake, electric brake/clutch, electrical components, etc., can solve the problems of coupling failure and unfavorable equipment, and achieve convenient processing and transformation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

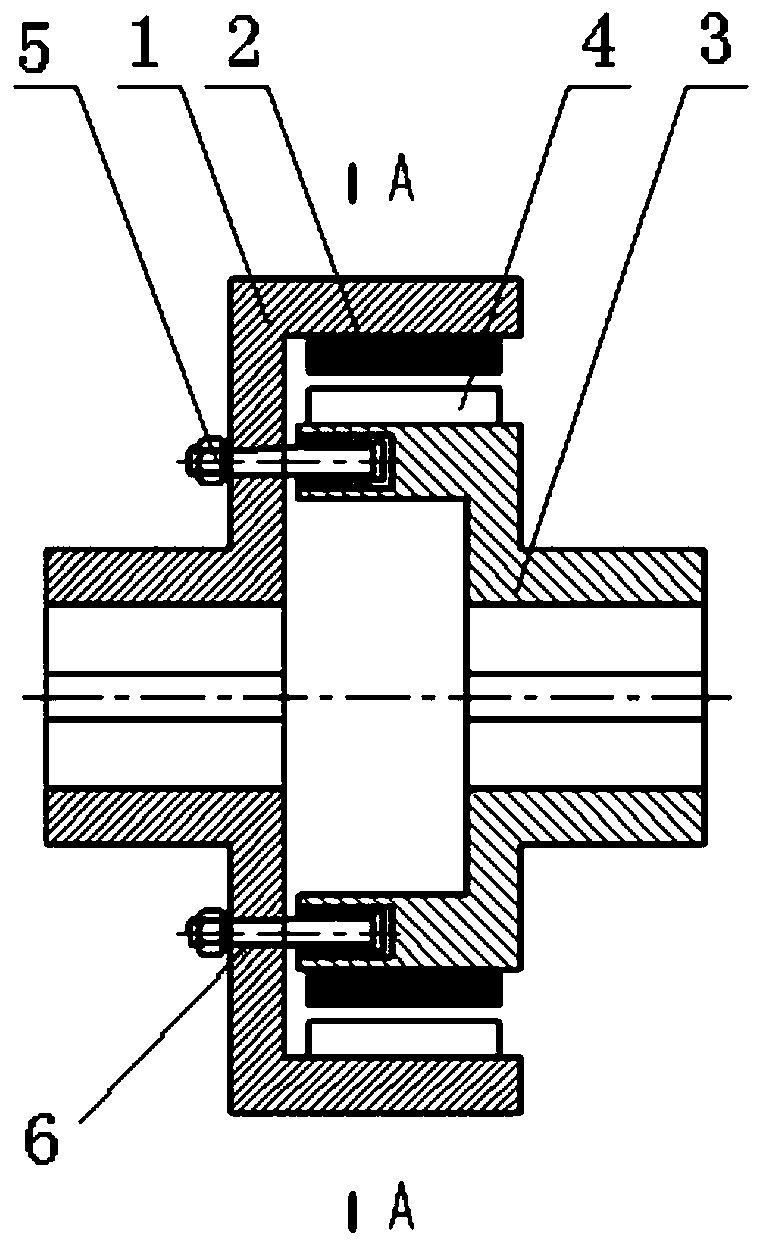

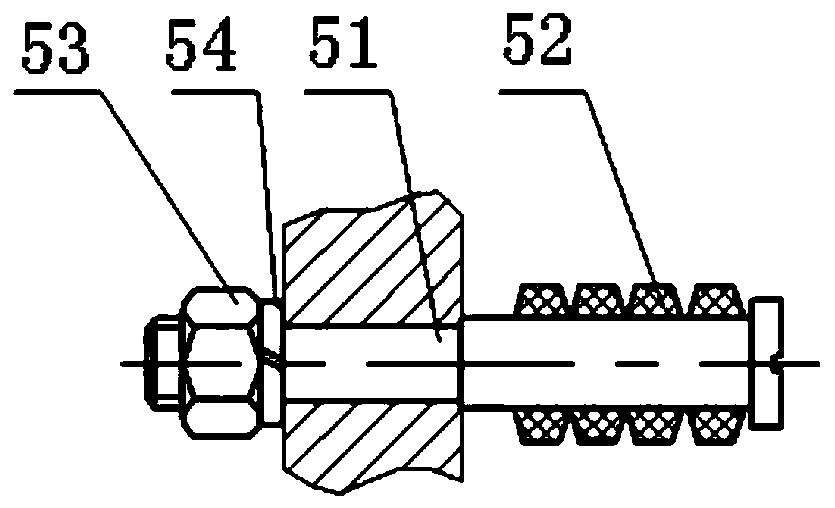

[0051] This embodiment provides a specific implementation of a magnetic coupling, specifically a synchronous cylindrical structure, such as figure 1 As shown, it includes a driving rotor 1, a driven rotor 3 and a connecting structure 5 fixedly arranged on one of the driving rotor 1 and the driven rotor 3, and a connection structure 5 arranged on the driving rotor 1 and the driven rotor 3. The limiting structure on the other of the moving rotor 3.

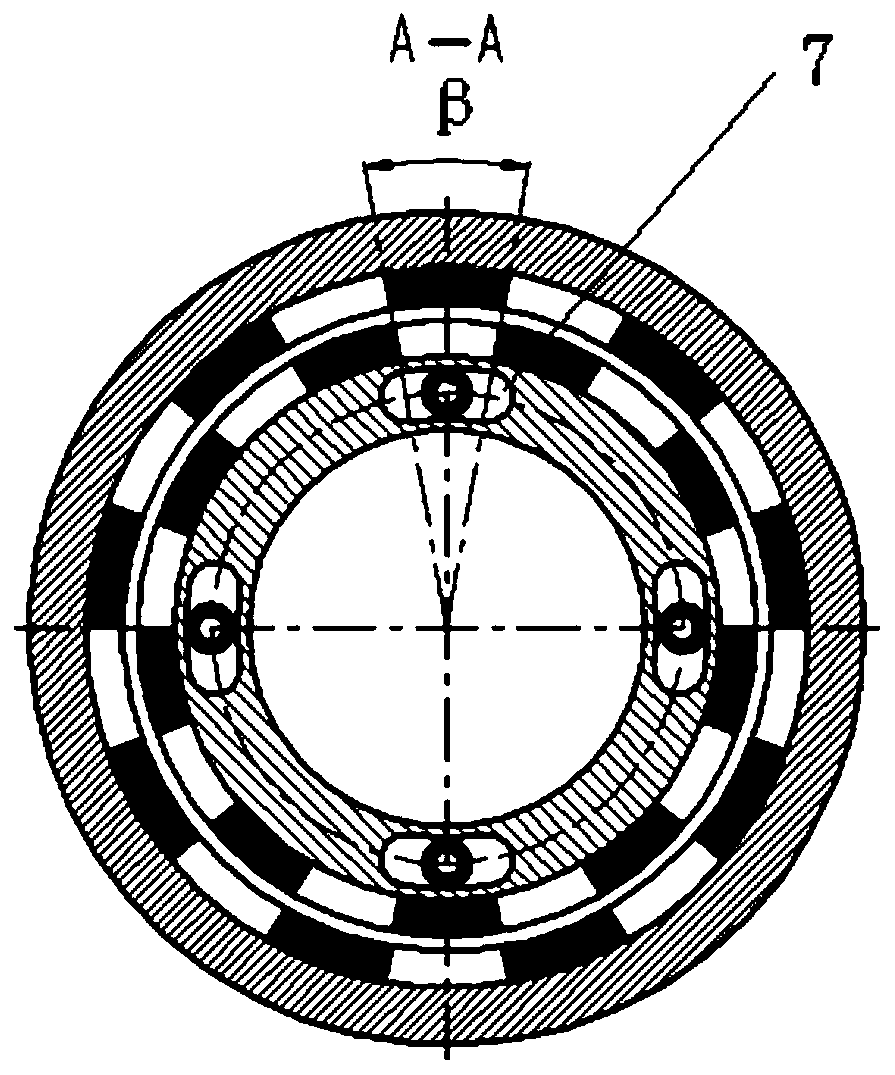

[0052] Wherein the driving rotor 1 is provided with a first permanent magnet 2; the driven rotor 3 is provided with a second permanent magnet 4 that forms a magnetic coupling with the first permanent magnet 2, and the first permanent magnet 2 and the second There is an air gap between the permanent magnets 4 , and the number of magnetic pole pairs of the first permanent magnet 2 and the second permanent magnet 4 is n respectively. Such as figure 2 As shown, the magnetic circuits of the first permanent magnet 2 and the second perm...

Embodiment 2

[0072] This embodiment provides a magnetic coupling with synchronous disc structure, such as Figure 7 with Figure 8 As shown, it includes a driving rotor 1, a driven rotor 3, and a connecting structure 5 fixedly arranged on one of the driving rotor 1 and the driven rotor 3, and a connecting structure 5 arranged on the driving rotor 1 and the driven rotor 3. The limiting structure on the other of the moving rotor 3.

[0073] For the setting of the connecting structure 5 and the limiting structure, refer to the setting of the connecting structure 5 and the limiting structure in the above-mentioned embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com