Cutter for printed substrates

A technology for printing substrates and cutting machines, applied in the field of advertising boards, can solve problems such as time-consuming, and achieve the effect of reducing time and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

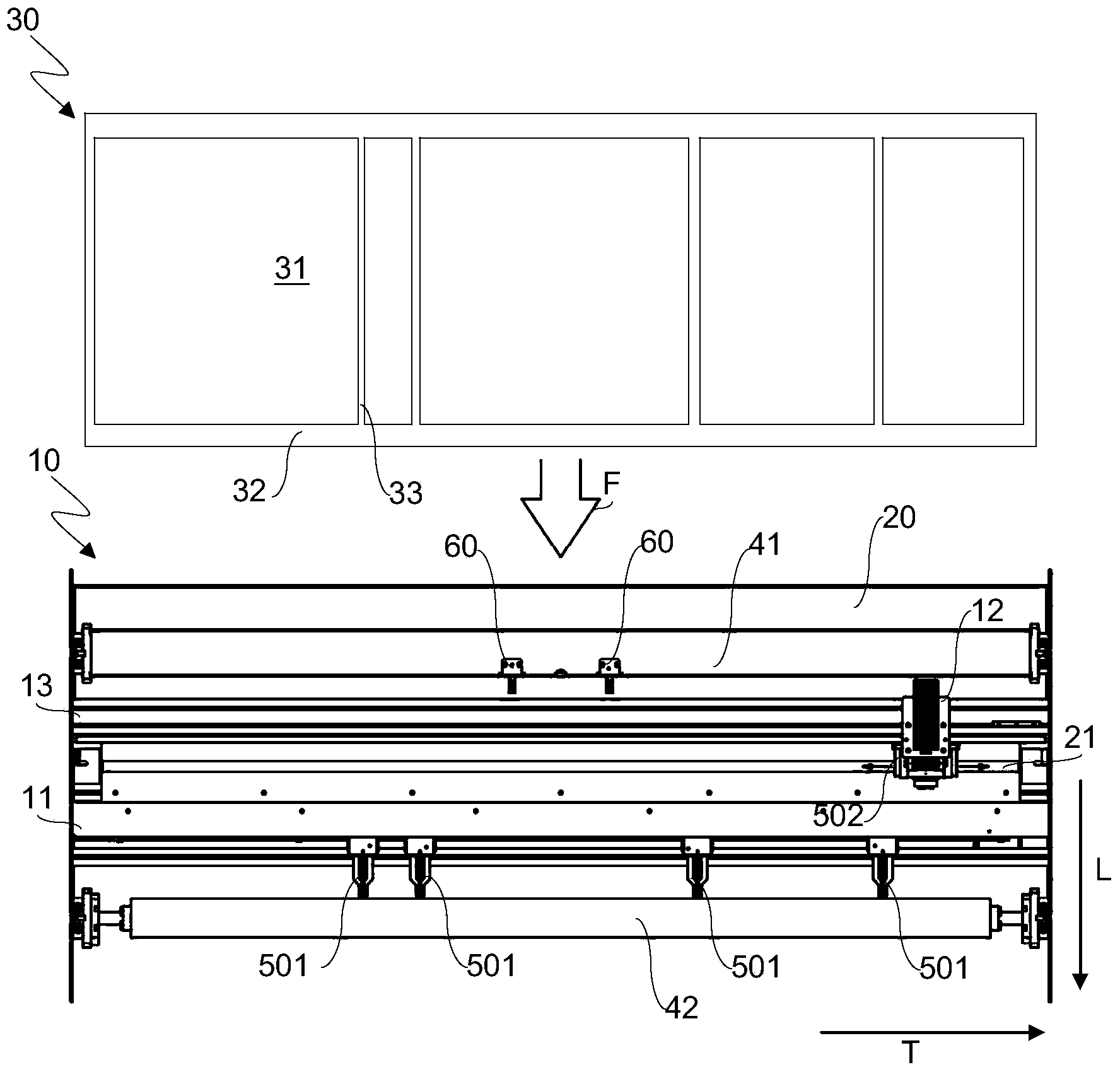

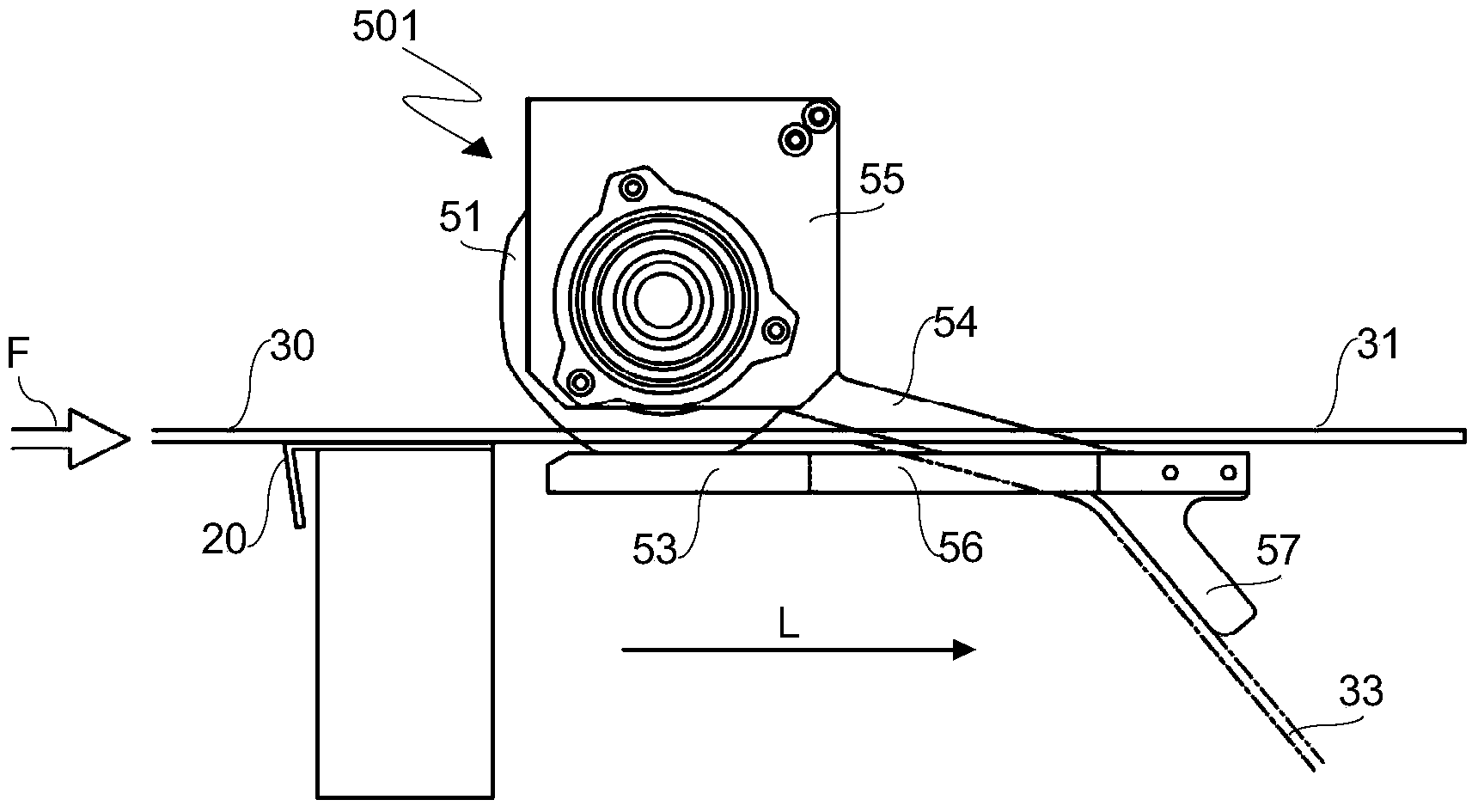

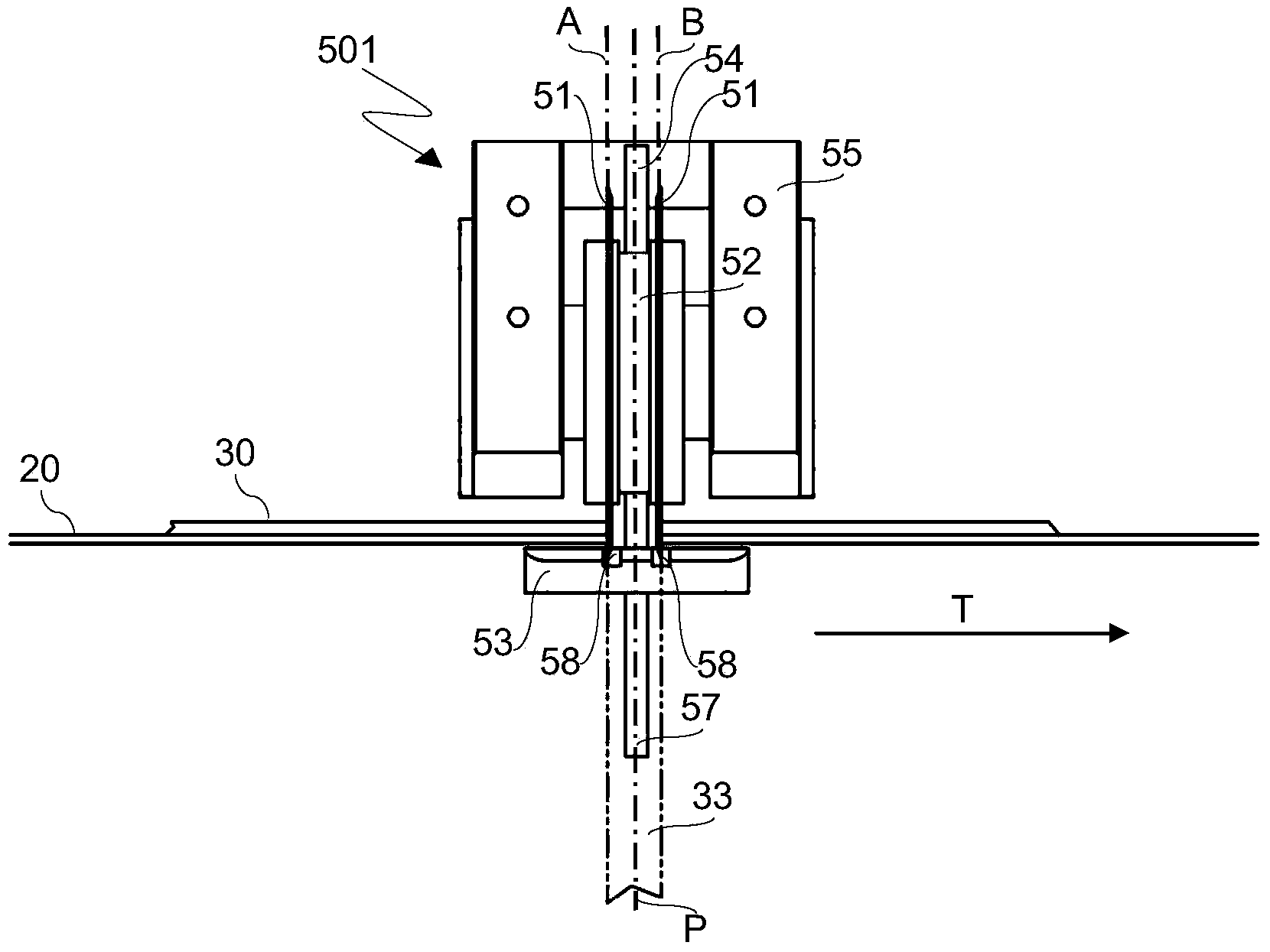

[0021] refer to figure 1 The cutting machine 10 according to the invention comprises a support plane 20 adapted to receive a printed substrate 30 comprising a plurality of pictures 31 separated by a plurality of sides 32, 33 perpendicular to each other. The cutting machine 10 also includes at least one input drum 41 and at least one output drum 42, at least one input drum 41 and at least one output drum 42 are adapted to drag the substrate 30 through the at least one feed direction shown by arrow F in the figure. An input drum 41 and at least one output drum 42 .

[0022] The cutting machine 10 is also provided with a plurality of cutting units, generally indicated by reference numeral 50, arranged for cutting in two mutually perpendicular directions (in particular in a longitudinal direction L parallel to the feed direction F and perpendicular to Transverse T to the feed direction F) the printed substrate 30 is cut along the edges 32 , 33 .

[0023] The cutting machine 10 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com