Machine tool

A machine tool and robot technology, applied in the direction of manipulators, metal processing machinery parts, manufacturing tools, etc., can solve problems that cannot be used to combine robots, time-consuming, and non-production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the accompanying drawings.

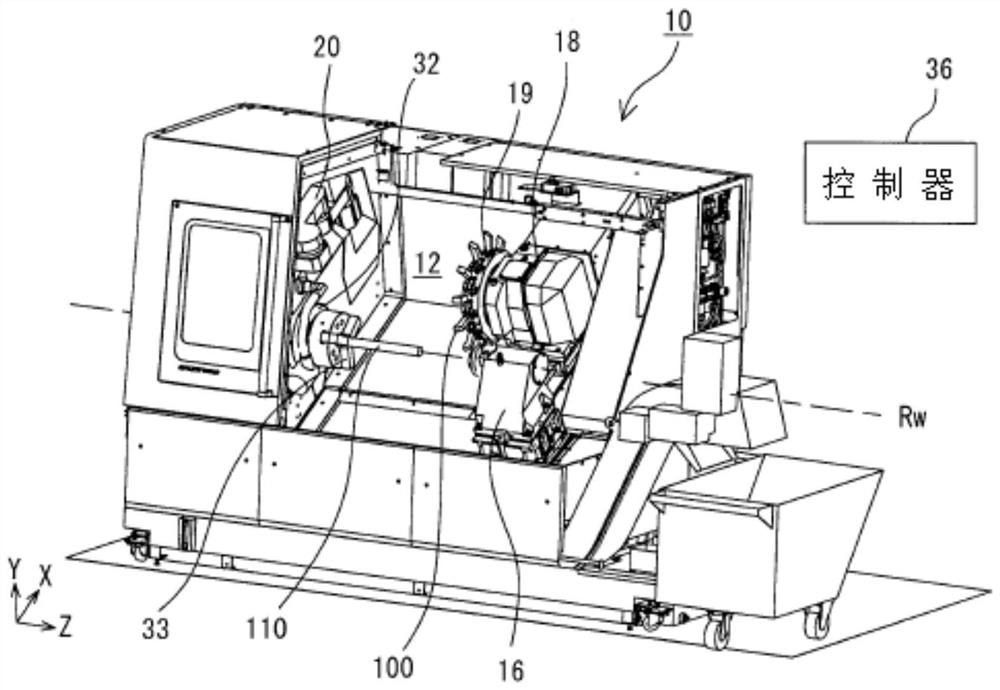

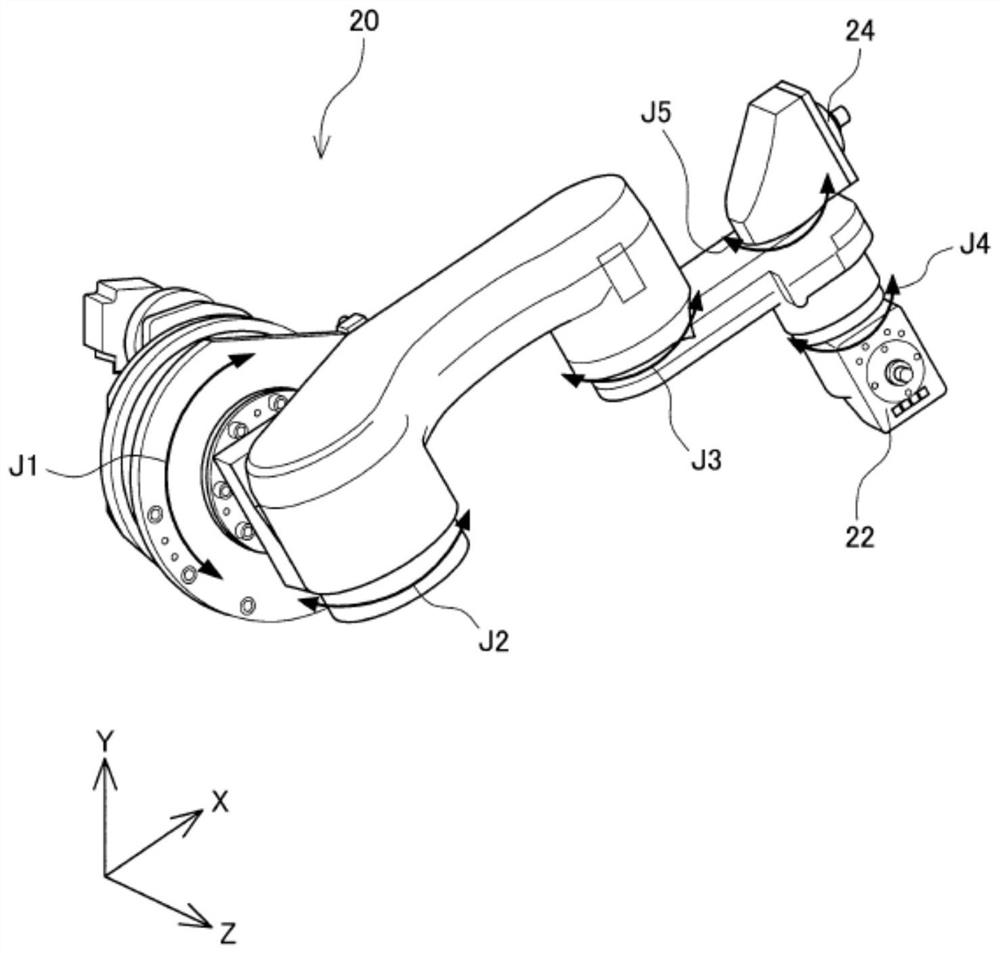

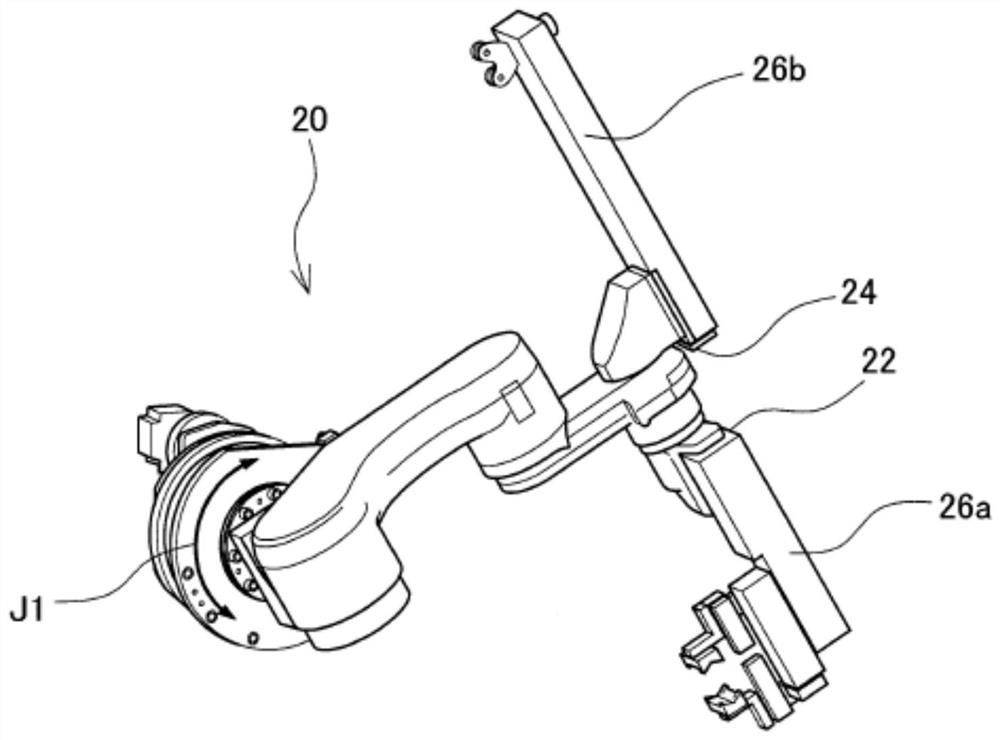

[0032] figure 1 The structure of the machine tool 10 is shown. In the following description, the direction parallel to the workpiece rotation axis Rw of the workpiece spindle 32 is referred to as the Z axis, the direction parallel to the moving direction of the tool post 18 perpendicular to the Z axis is referred to as the X axis, and the direction parallel to the X axis and The direction in which the Z axes are all perpendicular is called the Y axis. On the Z axis, the direction directed from the workpiece spindle 32 to the tailstock 16 is defined as the positive direction; on the X axis, the direction directed from the workpiece spindle 32 to the tool rest 18 is defined as the positive direction; on the Y axis, the upward direction from the workpiece spindle 32 The direction of is defined as positive. In the following description, the expression that the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com