Apparatus for processing ground surfaces

一种设备、地表的技术,应用在处理地表的设备领域,能够解决施工机械加速等问题,达到改进安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

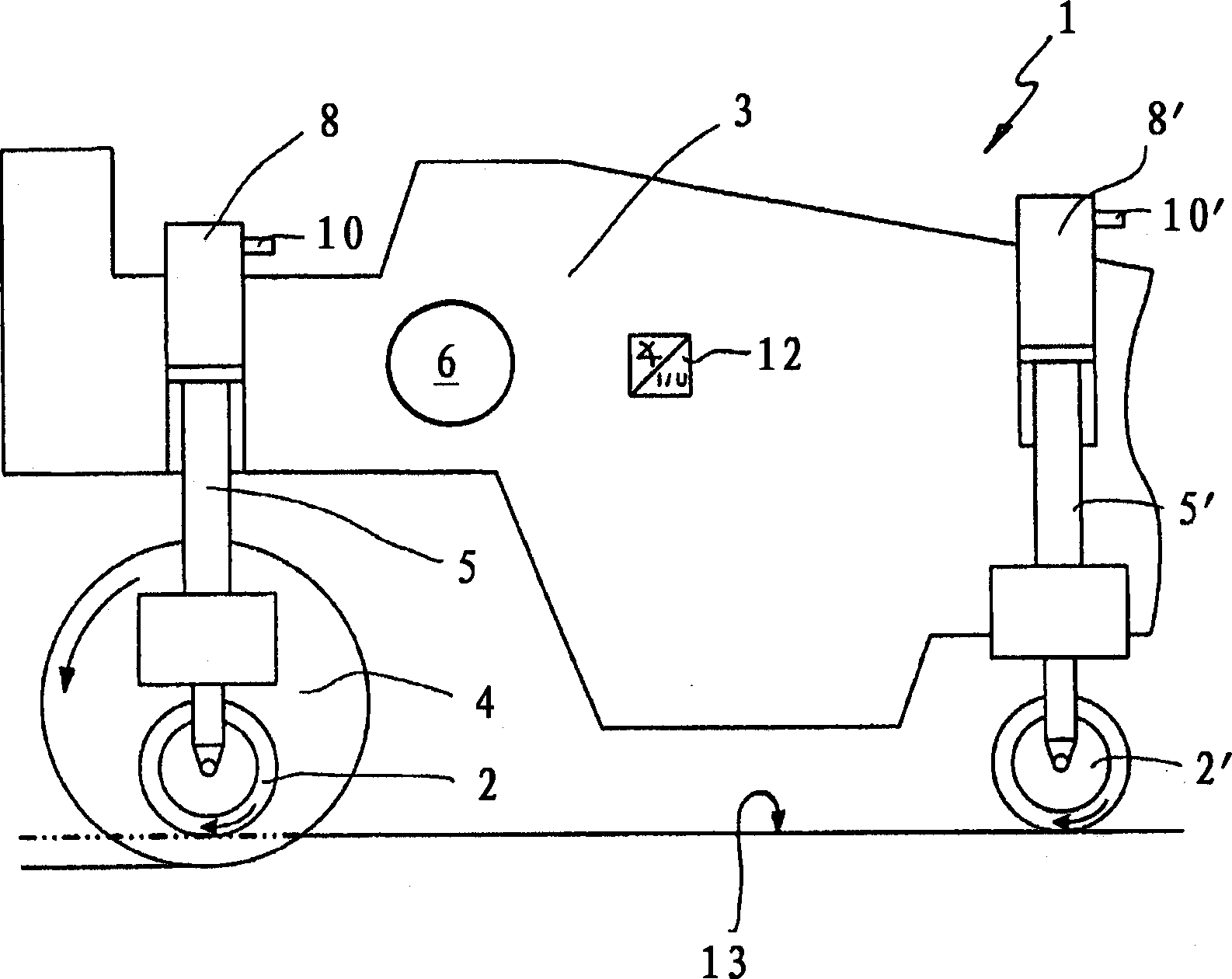

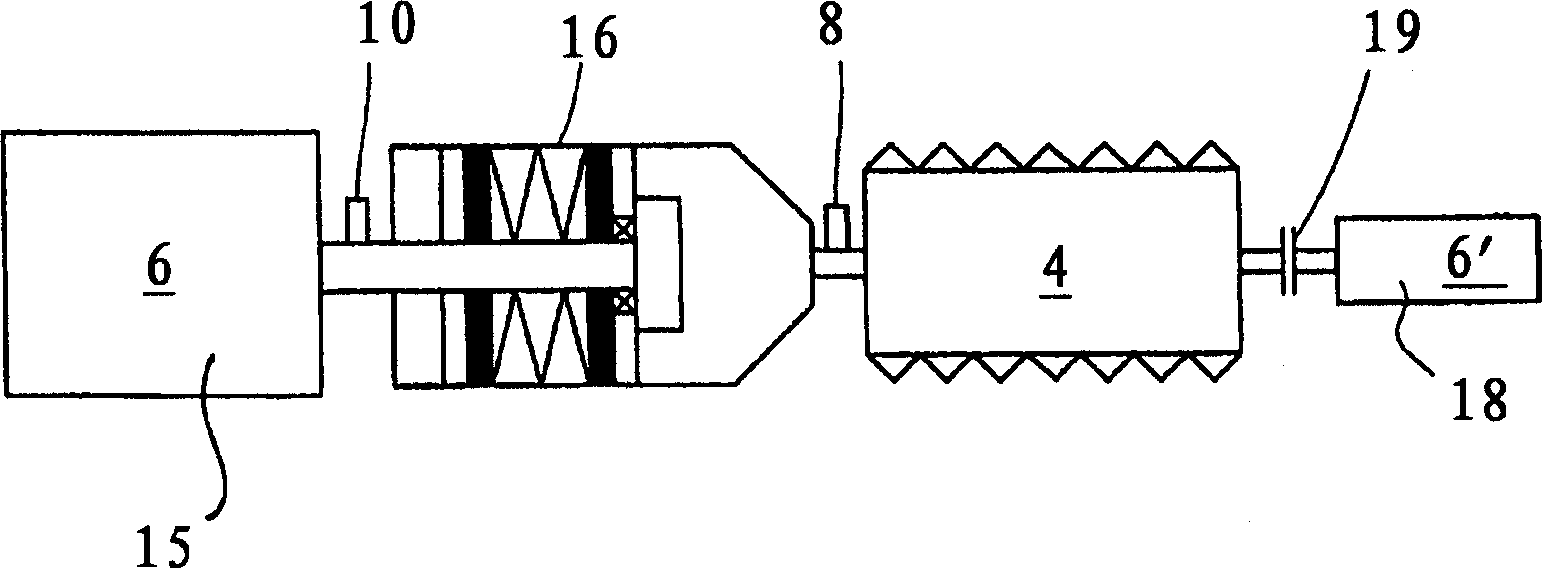

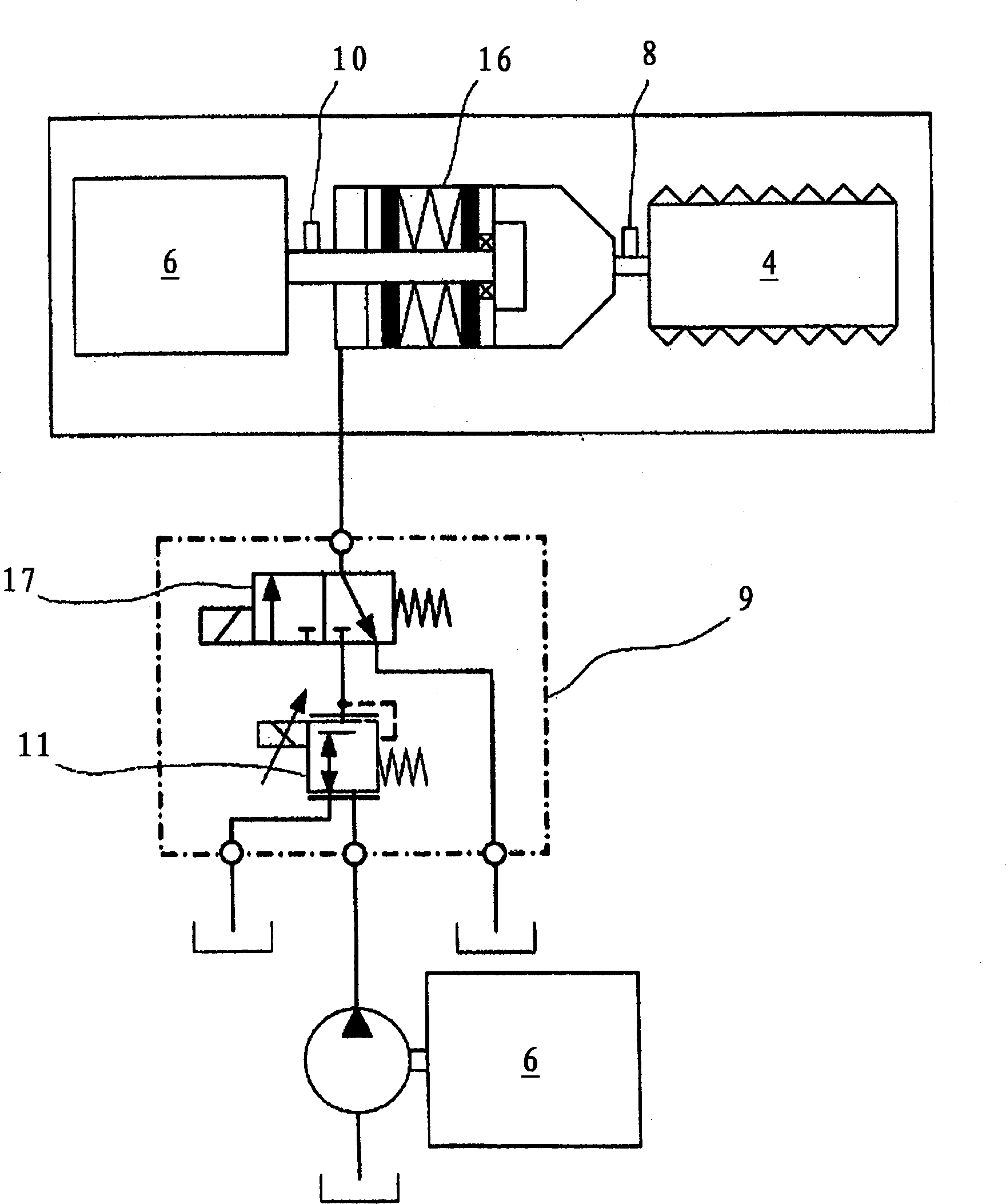

[0041] Such as figure 1 The equipment or construction machine 1 for processing the ground shown in FIG. 1 includes a frame 3 and a driving device 6. The driving device 6 is used to drive the moving device 2 and the working device 4, in this example the working device is a milling device. In this embodiment, the movement device 2 is composed of wheels. The milling device 4 can be separated from the driving device 6 by means of a coupling device (not shown), and can be brought into a lifting position (not shown) by means of a lifting device 5 on the frame 3.

[0042] The lowered position shown here corresponds to the working position or the working stroke of milling the ground surface 13 shown. As shown in the figure, during the working stroke, the rotation direction of the working device 4 is opposite to the movement direction of the equipment 1 or the rotation direction of the wheel 2. In the raised position or the maneuvering position (not shown), the working device 4 is no lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com