Full-automatic drug sterility inspection enrichment system of sterile bin and operation method of system

A fully automatic technology for sterility inspection, applied in the preparation, sampling, and measuring devices of test samples, which can solve problems such as potential safety hazards, high operation error rate, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

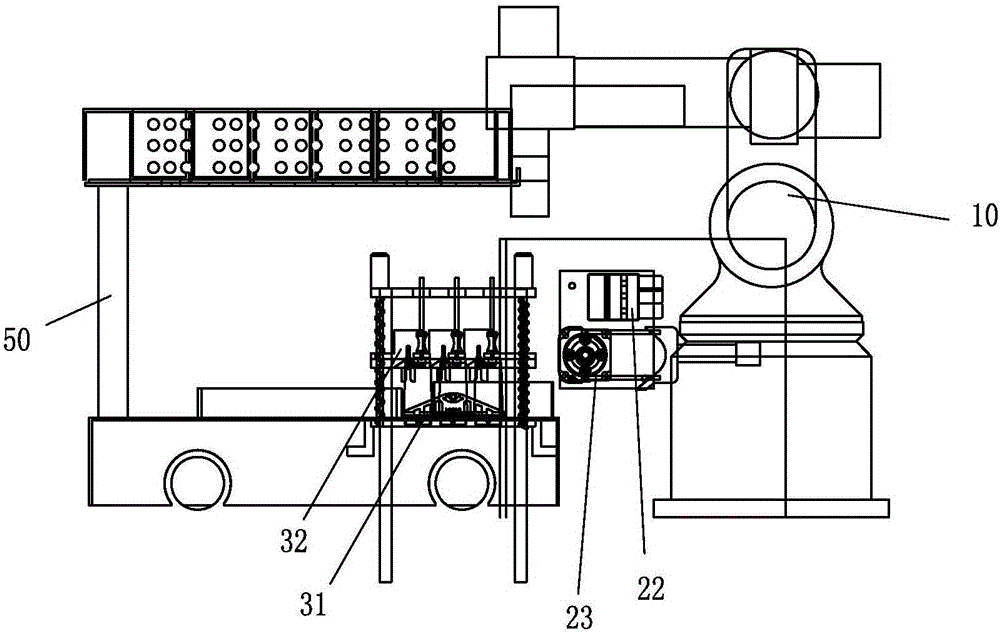

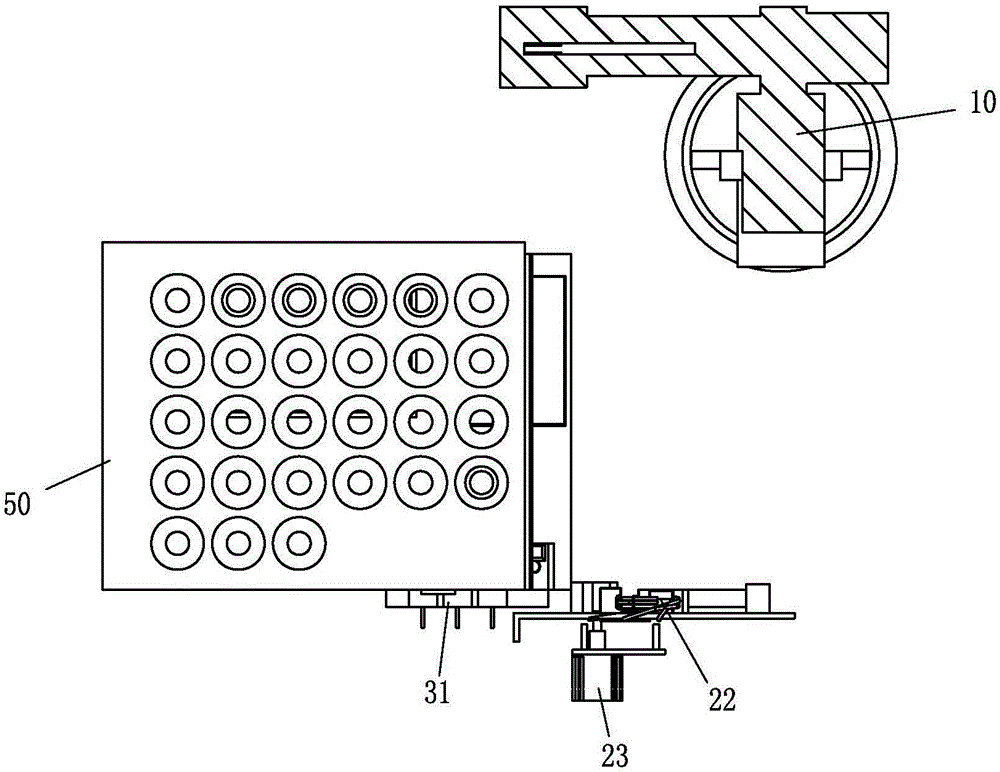

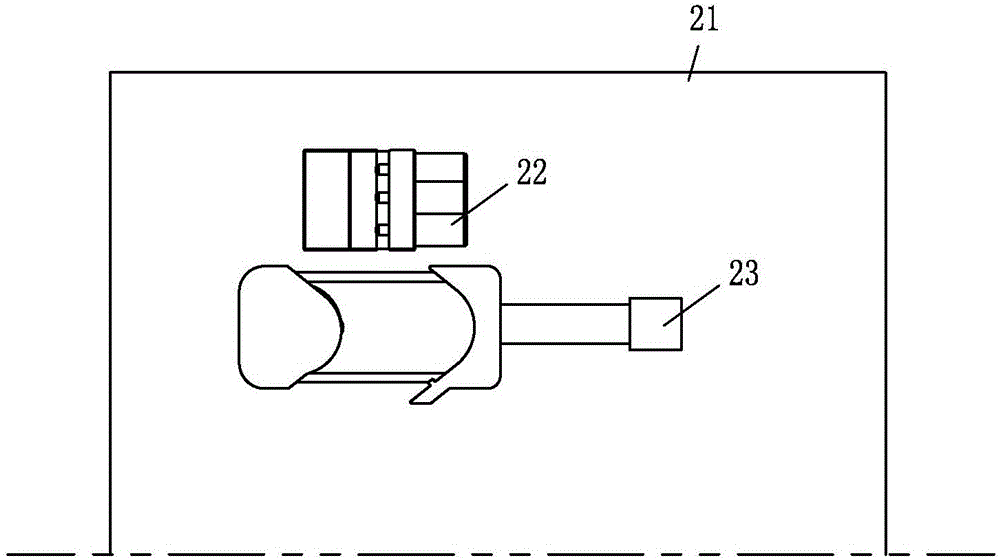

[0085] Such as Figure 1 to Figure 6 As shown, the aseptic chamber automatic drug sterility inspection and enrichment system of the present invention includes an unmanned, aseptic work vehicle 50 that is automatically positioned to the work station, and an automatic work hand 10 (robot gripper or station manipulator, etc., not limited) and be located at the work station and when the aseptic work vehicle 50 arrives at the work station, it can move forward close to the operation platform 21 of the aseptic work vehicle 50, wherein: as Figure 5 , the aseptic work vehicle 50 can include a vehicle base 52, which is provided with a waste water tank 54, a filter placement box 55, and a garbage box 56, and above the water inlet 541 on the top of the waste water tank 54 is provided with at least one for placing to be operated. The filter hole position 57 of the filter, the design of the filter hole position 57 located above the water inlet 541 of the waste water tank 54 is to facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com