Initial positioning system and method for fluid flowmeter measuring

A technology for initial positioning and liquid measurement, which is applied in the directions of volume measurement instruments/methods, chemical instruments and methods, liquid/fluid solid measurement, etc. Large-scale promotion and application of containers and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

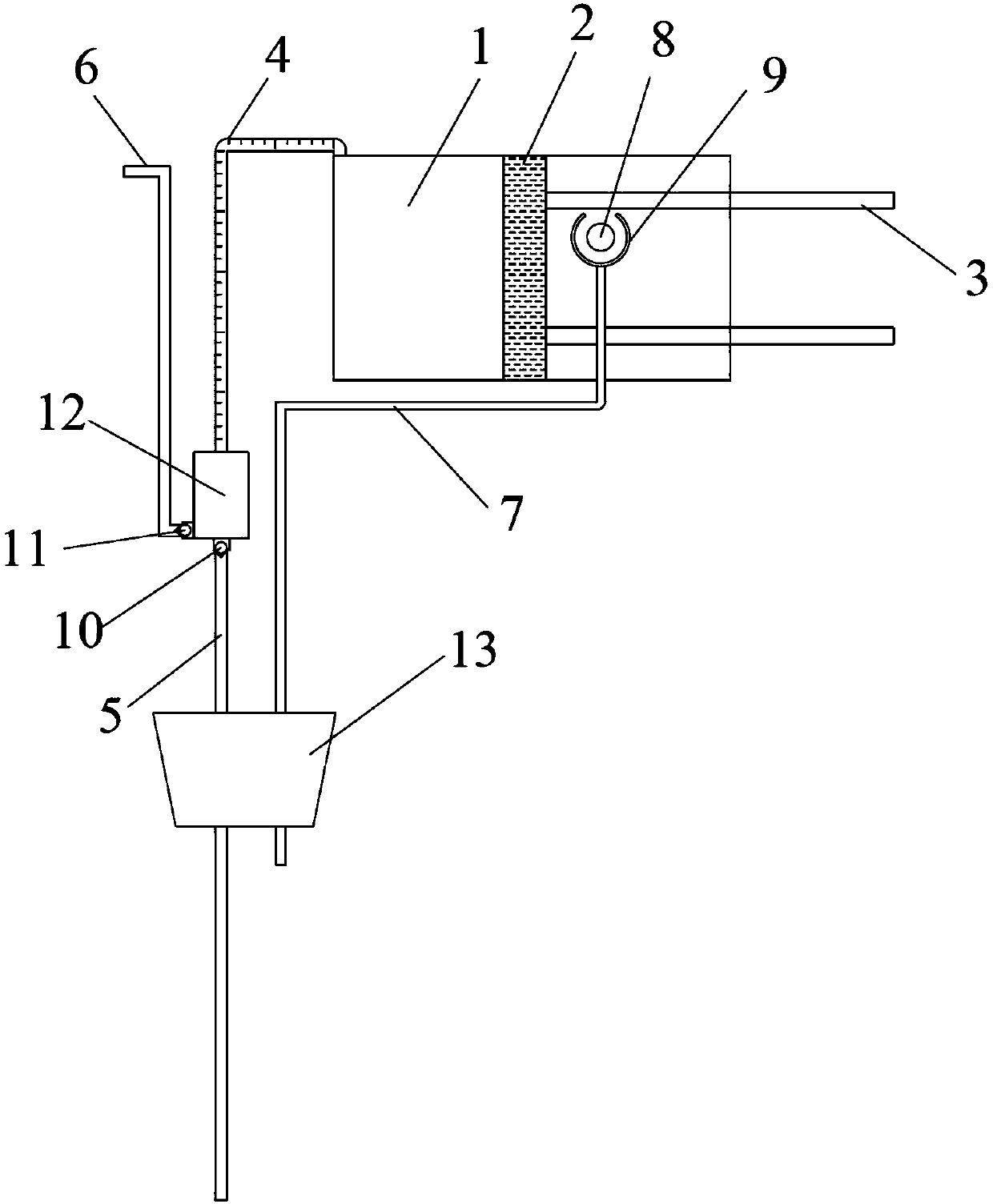

[0030] figure 1 Shown is a schematic structural view of a metering tool including an initial positioning system for liquid metering and taking according to Embodiment 1. The initial positioning system of the metering tool includes a variable pressure chamber 1 , a piston 2 , an operating rod 3 , a metering channel 4 and a pressure relief port 8 . Among them, the piston 2 is located at the horizontal side of the variable pressure chamber 1, the metering channel 4 is connected to the upper part of the variable pressure chamber 1, and the pressure relief port 8 is located at the middle and upper part of the horizontal position of the variable pressure chamber 1, passing through the wall of the variable pressure chamber 1, when the piston 2 reciprocates It can cross the pressure relief port 8 and reach the right side of the pressure relief port 8. When the piston 2 is located at the position of the pressure relief port 8 and the inside and outside of the variable pressure chamber...

Embodiment 2

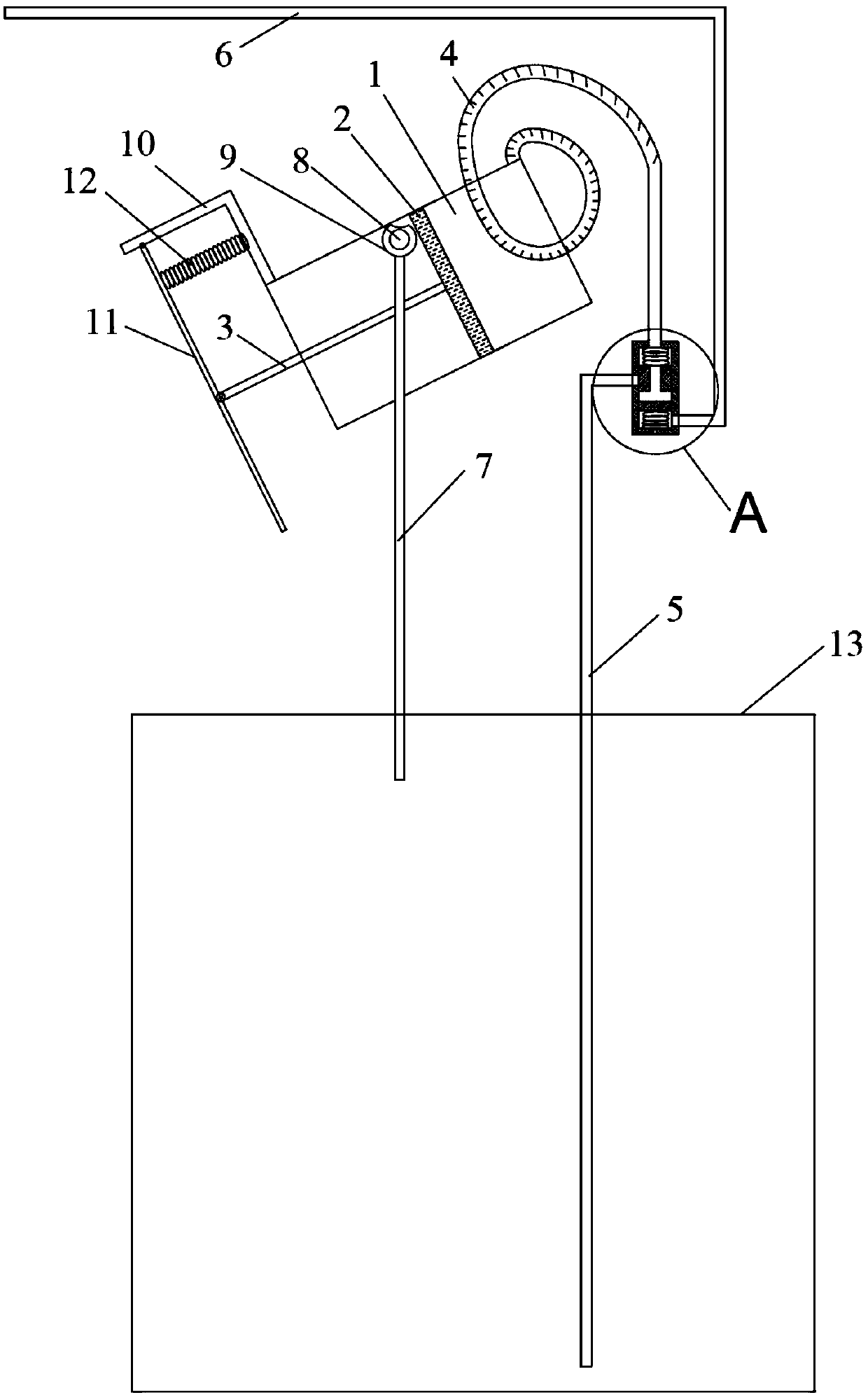

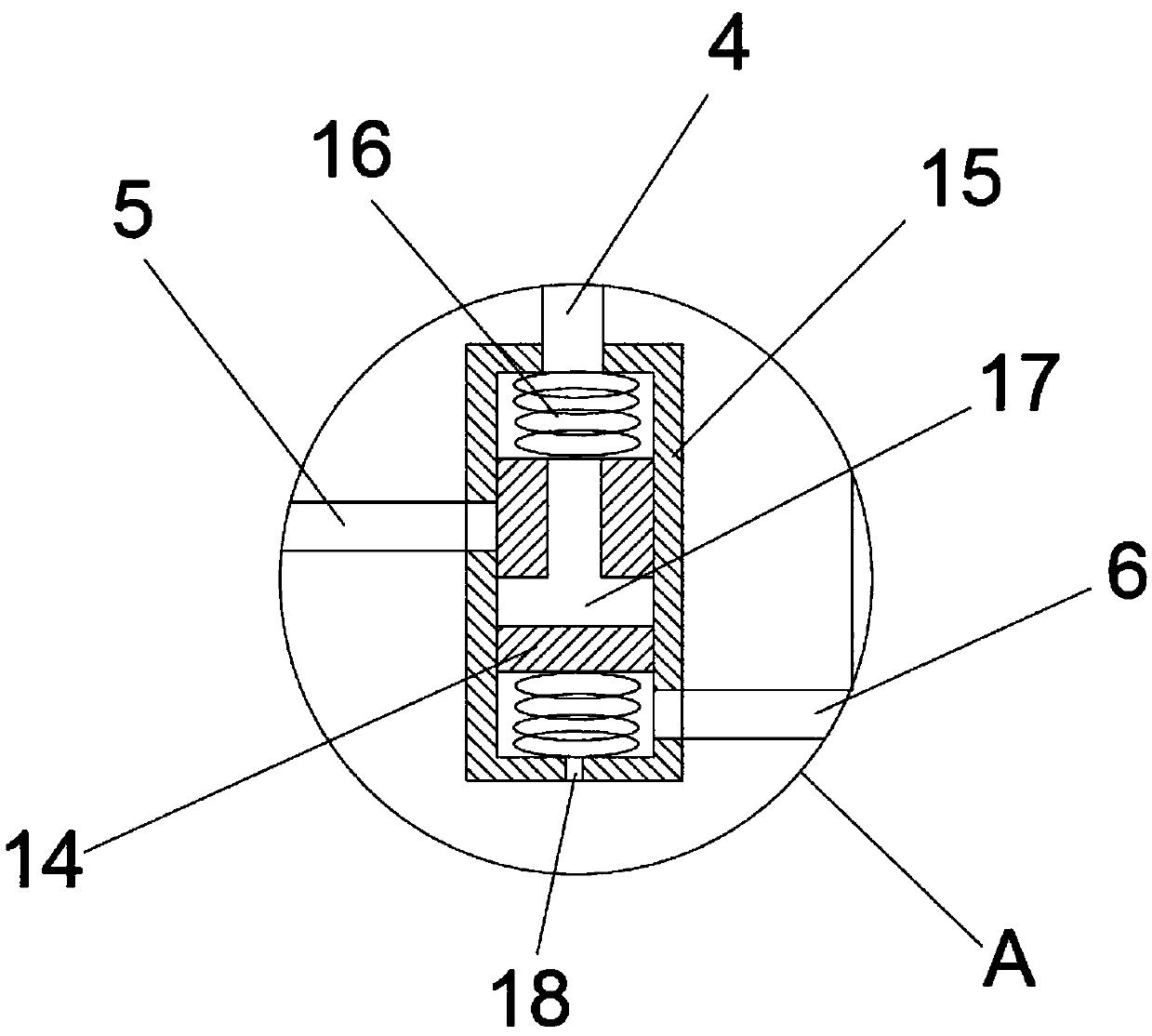

[0038] figure 2 Shown is a schematic structural view of the liquid metering and taking container according to embodiment 2, image 3 It is a partially enlarged view of the liquid metering and taking container A described in Example 2.

[0039] The liquid metering and taking container includes an initial positioning system composed of a pressure-changing chamber 1, a piston 2, a connecting rod 3, a metering channel 4, and a pressure relief port 8, and also includes a bowl 9 covering the outside of the pressure relief port 8, a backflow Channel 7, liquid intake channel 5, outflow channel 6, steering valve and container main body 13, as well as facilities for convenient access operation, including bracket 10 fixed on the outer wall of pressure-transforming chamber 1, movable link with bracket 10 and connecting rod 3 An operating rod 11, a spring 12 located between the bracket 10 and the operating rod 11.

[0040] Among them, the piston 2 is located obliquely below the variable...

Embodiment 3

[0051] Figure 4 Shown is a schematic structural view of a liquid metering and taking container according to Embodiment 3. The liquid metering and taking container includes an initial positioning system composed of a pressure-changing chamber 1, a piston 2, a connecting rod 3, a metering channel 4, and a pressure relief port 8 that opens a valve under a certain pressure. 8 The external return channel 7, the upper part of the return channel 7 is provided with an opening 9, the liquid intake channel 5 and its internal one-way valve 10, the outflow channel 6 and its internal one-way valve 11, the container main body 13, and the electric device connecting the connecting rod 3 12.

[0052] Among them, the piston 2 is located below the pressure changing chamber 1, the metering channel 4 is connected to the upper right part of the pressure changing chamber 1, and the pressure relief port 8 is located at the lower part of the horizontal position of the pressure changing chamber 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com