Method for realizing reliability maintenance planning of high temperature pipeline system

A system implementation and reliability technology, used in piping systems, testing of machine/structural components, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

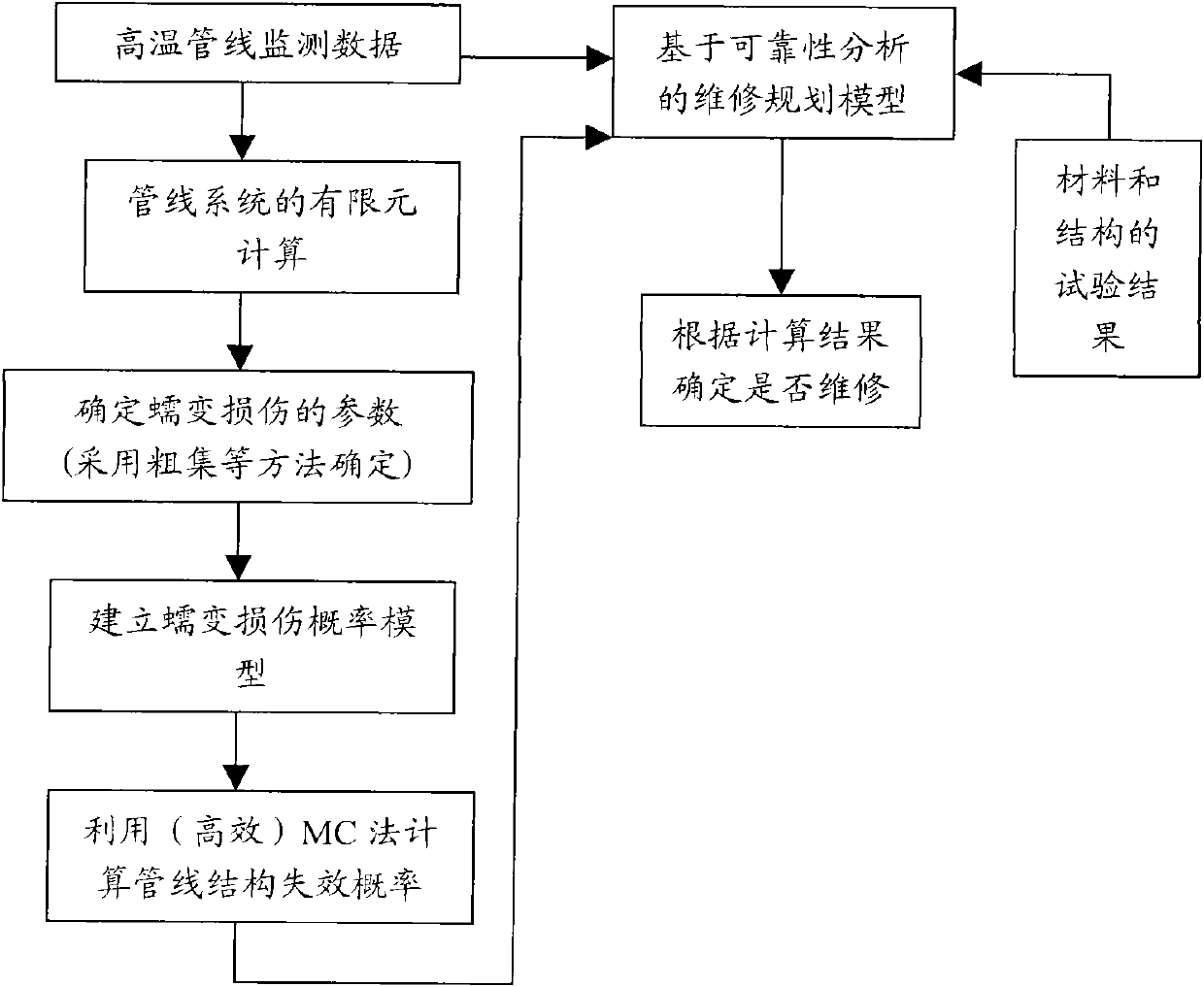

[0079] see figure 1 As shown, the high temperature pipeline system realizes the method of reliability maintenance planning, which includes the following steps:

[0080] (1) Collect and acquire the detection data of the high-temperature pipeline system;

[0081] (2) Carry out finite element calculation of the high temperature pipeline system according to the detection data;

[0082] (3) Determine the creep damage parameters of the high-temperature pipeline system according to the degree of influence of various factors on the life of the high-temperature pipeline, including the following steps:

[0083] (a) Reduce the influence of highly nonlinear and random factors in the material test data of high-temperature pipelines, reduce the randomness of the data, and reduce the degree of nonlinearity of the data; the reduction of the randomness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com