Power station high-temperature pipe system maintenance method based on non-probability reliability theory

A pipeline system and reliability technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of enterprise economic and social security impact, high temperature pipeline system of power station prone to failure, and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

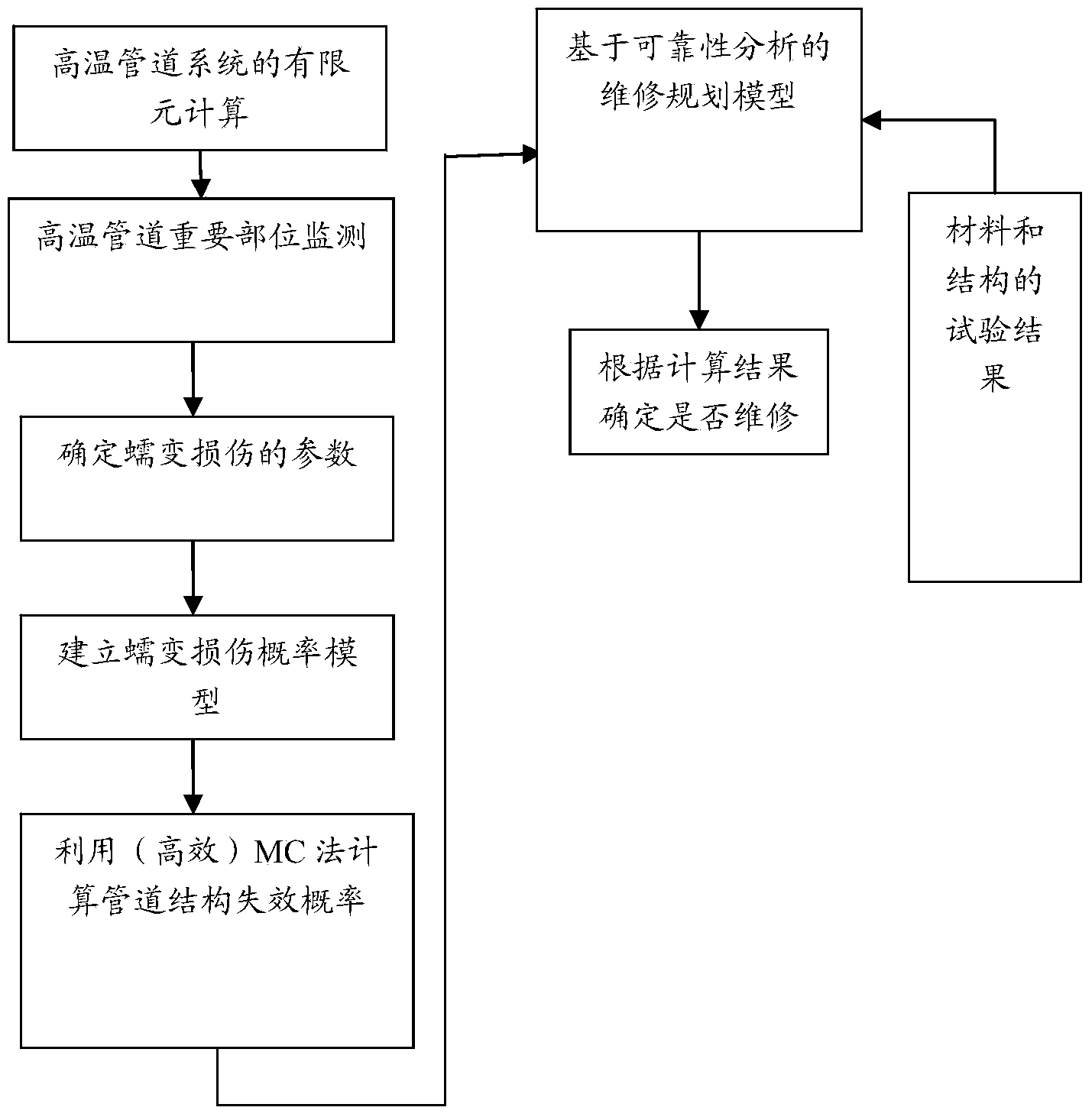

[0094] see figure 1 As shown, the high temperature pipeline system maintenance method of the present invention comprises the following steps:

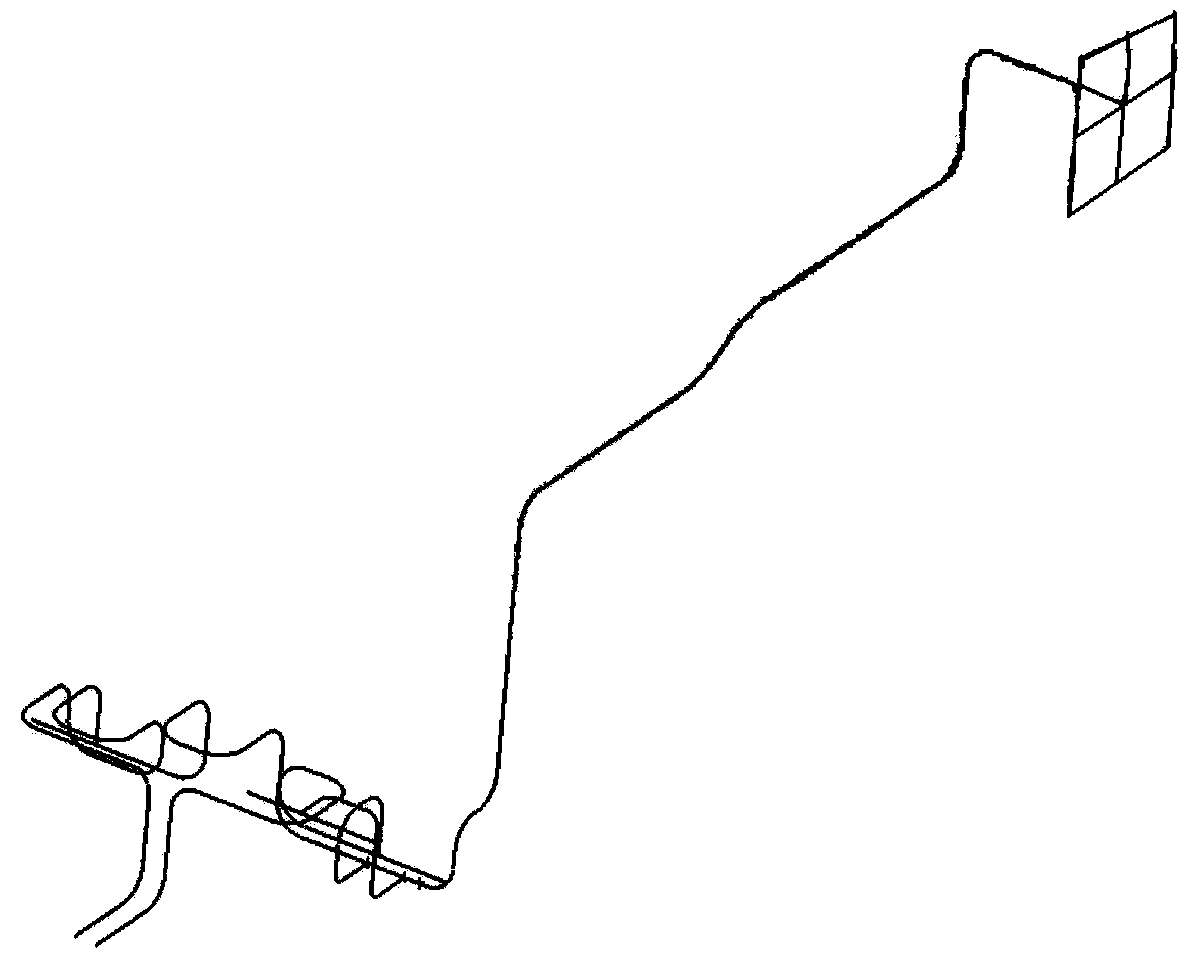

[0095] 1. First, carry out the finite element calculation of the high-temperature piping system of the power station, and determine the key detection parts of the high-temperature piping system of the power station according to the place of maximum stress;

[0096] 2. Arrange fixed sensors at key locations, and collect detection data with the method of comprehensive detection system of infrared thermal imaging monitoring instrument;

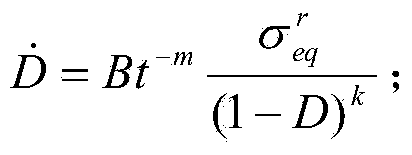

[0097] 3. According to the theory of non-probabilistic reliability, the creep damage random parameters of the high-temperature piping system of the power station are determined, including the following steps:

[0098] (a) Determine the mean value, standard deviation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com