Method for preparing large-scale graphene through supercritical carbon dioxide exfoliation

A carbon dioxide and supercritical technology, applied in the production of graphene, nano-carbon, bulk chemicals, etc., can solve the problems of high pressure, high toxicity of organic solvents, low output, etc., to increase the number of boost and step-down, and widely used Prospects, effects of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

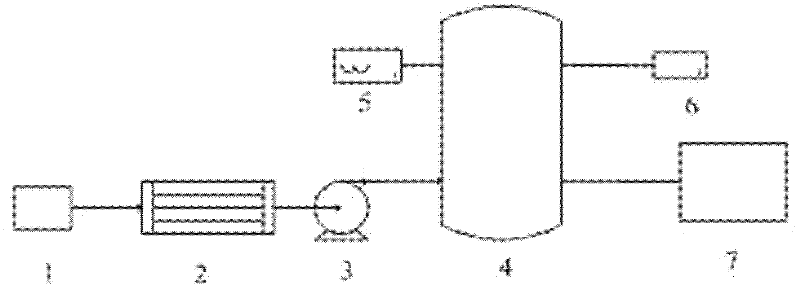

Method used

Image

Examples

Embodiment 1

[0023] A certain amount of sodium lauryl sulfate is mixed with graphite powder, and the weight ratio of graphite powder and sodium lauryl sulfate is 1:5, and is added in the autoclave 4. The autoclave temperature was set at 65°C, and the control temperature was 40°C. The carbon dioxide is pumped into the autoclave 4 by the pump 3, and the pressure in the still is controlled at 18MPa. The material stays in the autoclave 4 for 120 minutes. Through testing and characterization, graphene with less than 10 layers in the product accounts for 42%.

Embodiment 2

[0025] A certain amount of sodium dodecylbenzenesulfonate is mixed with graphite powder, and the weight ratio of graphite powder and sodium dodecylbenzenesulfonate is 1:6, and is added in the autoclave 4 . The material in the autoclave 4 is heated, and the temperature is controlled to 45°C. Carbon dioxide is pumped into the autoclave 4 by the pump 3, and the pressure in the still is controlled at 10MPa. The material stays in the autoclave 4 for 60 minutes. After a quick depressurization, the carbon dioxide is pumped in again through the pump 3. Repeat the pressurization and depressurization process three times. Through testing and characterization, graphene with less than 10 layers in the product accounts for 63%.

Embodiment 3

[0027] Ethanol was used as co-solvent. A certain amount of ethanol is mixed with graphite powder and added to the autoclave 4. The material in the autoclave 4 is heated, and the temperature is controlled to 55°C. Carbon dioxide is pumped in the autoclave 4 by the pump 3, and the pressure in the control kettle is at 12MPa. The material stays in the autoclave 4 for 30 minutes. After a quick depressurization, the carbon dioxide is pumped in again through the pump 3. Repeat the pressurization and depressurization process three times. A certain amount of ethanol is added to the pressure relief tank 7, and the valve is opened to quickly relieve the pressure. According to the test and characterization, the graphene with less than 10 layers in the product accounts for 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com