Low cost full-biodegradable polylactic acid sheet material and preparation method thereof

A polylactic acid and all-biological technology, applied in flat products, other household appliances, applications, etc., can solve the problems of limited promotion and application range, impact on physical properties of sheets, high price of polylactic acid sheets, etc., and achieve excellent plasticization extrusion Excellent output, excellent mechanical properties, stable melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

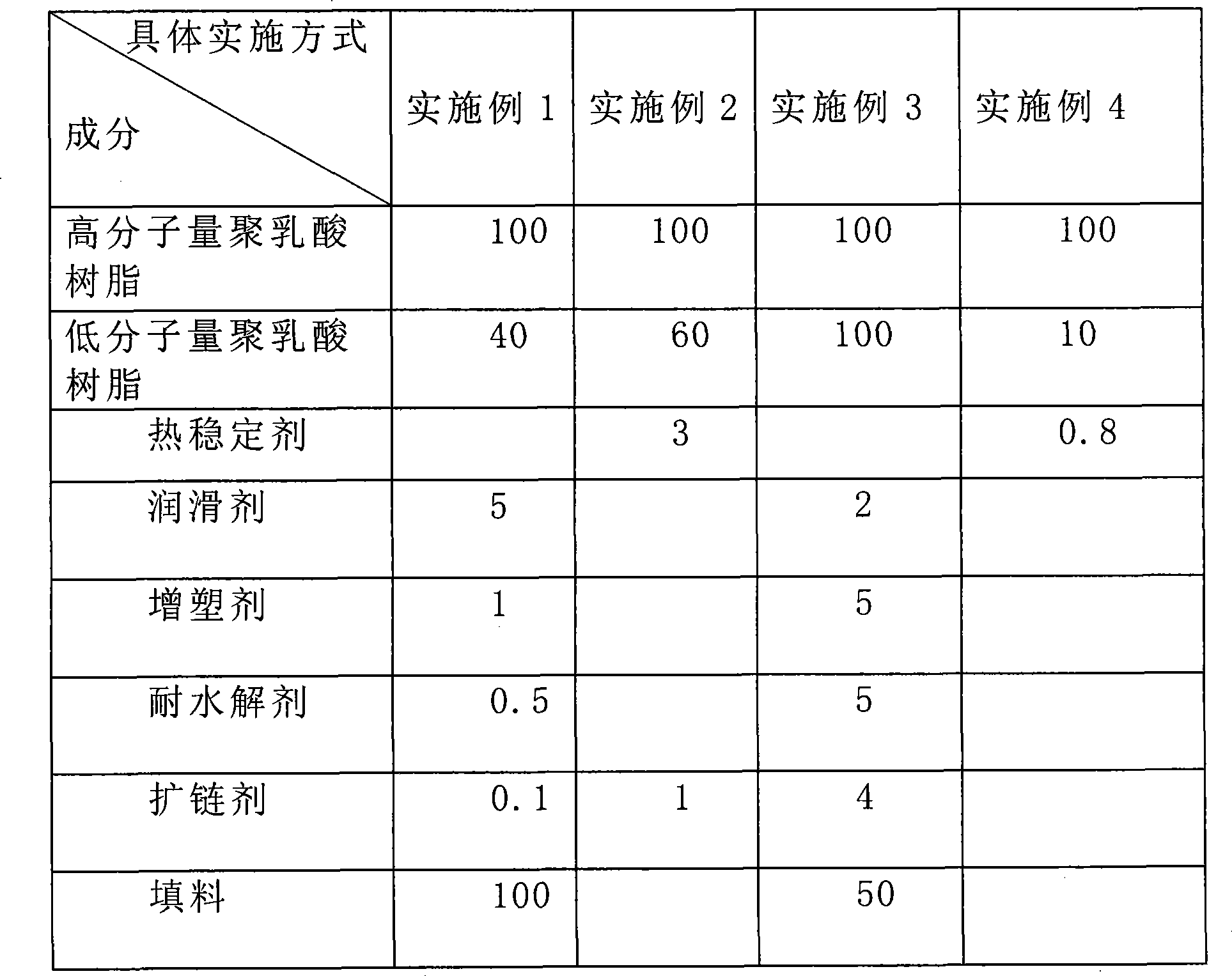

[0036] Embodiment 1: the making of non-transparent polylactic acid sheet

[0037] Take low-molecular-weight polylactic acid resin (i.e. low-molecular-weight polylactic acid resin through one or more processing) according to the weight portion of embodiment 1 in table 1, after stirring cold crystallization at low speed, then mix with high-molecular-weight polylactic acid resin (i.e. new Material polylactic acid resin) mixed and stirred evenly at a medium speed, first remove the moisture in the dry hot air through the molecular sieve system, and then dry under the condition of a closed cycle at a temperature of 80°C, after drying, the moisture content of the polylactic acid resin is less than 150ppm;

[0038] Add the processing aids and fillers of Example 1 in Table 1 to the dried polylactic acid resin, and mix the ingredients evenly after high-speed stirring. In the molecular state, it is fully mixed and a certain chemical reaction occurs; during the melting process, the moistu...

Embodiment 2

[0041] Embodiment 2: the making of transparent polylactic acid sheet

[0042] Take low-molecular-weight polylactic acid resin (i.e. low-molecular-weight polylactic acid resin through one or more processing) according to the weight portion of embodiment 2 in table 1, after low-speed stirring cold crystallization, then mix with high-molecular-weight polylactic acid resin (i.e. new Material polylactic acid resin) mixed with medium-speed stirring, first remove the moisture in the dry hot air through the molecular sieve system, and then dry under closed cycle conditions at a temperature of 90 ° C, after drying, the moisture content of the polylactic acid resin is less than 150ppm;

[0043] Add the processing aid of Example 2 in Table 1 to the dried polylactic acid resin, and mix the ingredients evenly after stirring at a high speed. Fully mixed in the state, and a certain chemical reaction occurs; in the melting process, the water in the melt and other small molecules are separated...

Embodiment 3

[0046] Embodiment 3: the making of non-transparent polylactic acid sheet

[0047] Take low-molecular-weight polylactic acid resin (i.e. low-molecular-weight polylactic acid resin through one or more processing) according to the weight portion of embodiment 3 in table 1, after low-speed stirring cold crystallization, then mix with high-molecular-weight polylactic acid resin (i.e. new Material polylactic acid resin) mixed at a medium speed and evenly stirred, first remove the moisture in the dry hot air through the molecular sieve system, and then dry under the condition of a closed cycle at a temperature of 100°C, after drying, the moisture content of the polylactic acid resin is less than 150ppm;

[0048] Add the processing aids and fillers of Example 3 in Table 1 to the dried polylactic acid resin, and mix the ingredients evenly after stirring at a high speed. In the molecular state, it is fully mixed and a certain chemical reaction occurs; during the melting process, the moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com