Formaldehyde-free self-crosslinked nanometer emulsion coating dye printing cementing substance and method for making same

A technology of nano-emulsion and adhesive, which is applied in the field of formaldehyde-free self-crosslinking nano-emulsion paint printing and dyeing adhesive and its preparation, which can solve the problems of environmental pollution, network blocking, network blocking, sticking rollers, etc., and improve printing and dyeing. The effect of fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

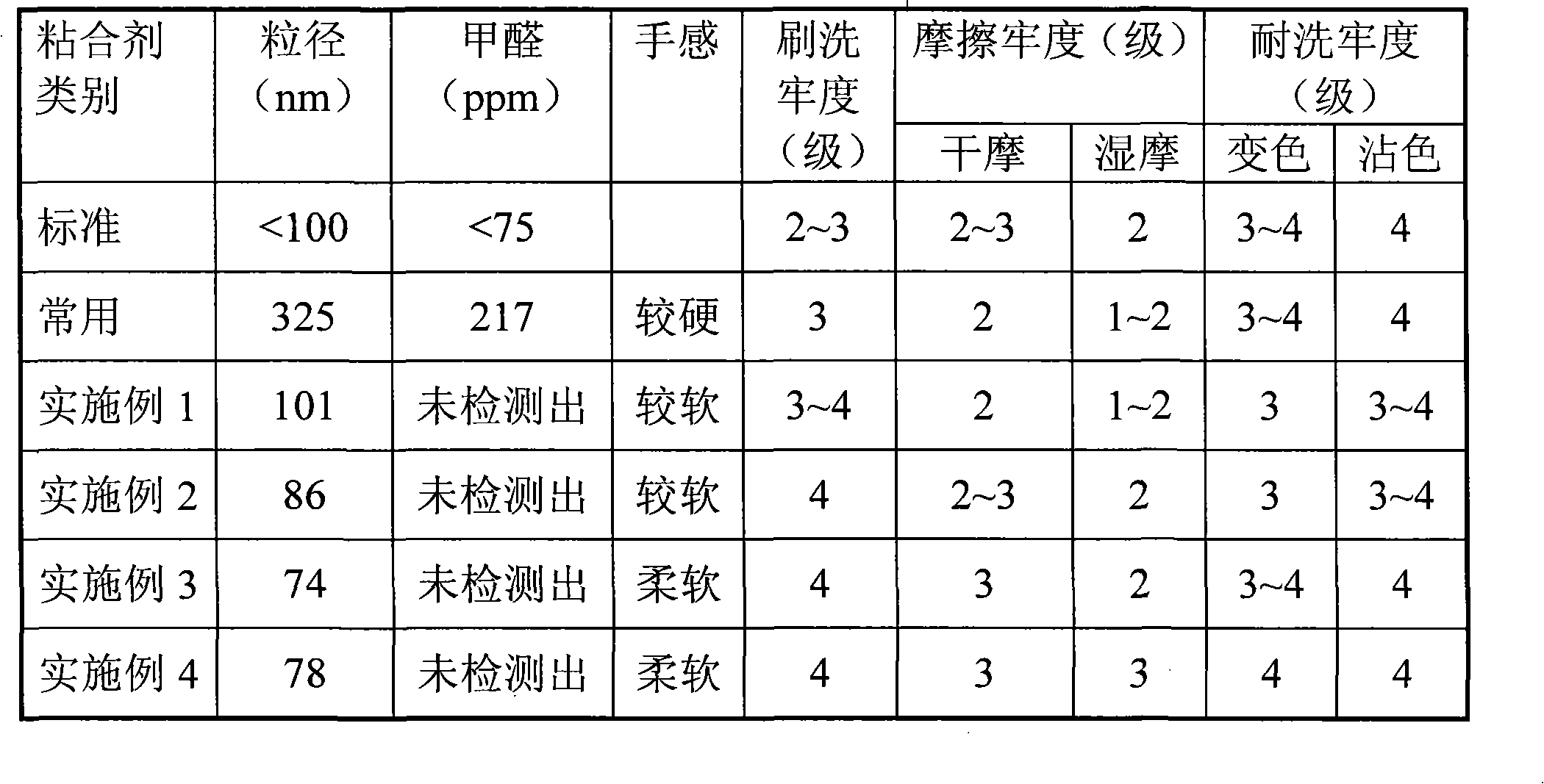

Embodiment 1

[0046] Adhesive emulsion polymerization formula (percentage of each component of the reaction system in the total mass of the monomer):

[0047] Hydroxyethyl acrylate and hydroxypropyl methacrylate 1~20

[0048] Ethyl acrylate and 2-ethylhexyl acrylate 20~80

[0049] Methacrylic acid 1~10

[0050] Methyl methacrylate 1~10

[0051] Styrene 0~5

[0052] Acrylamide 0~5

[0053] Ammonium persulfate 0.01~0.5

[0054] Sodium lauryl sulfate and octylphenol polyethylene glycol ether 2~5

[0055] Appropriate amount of deionized water

[0056] Synthesis:

[0057] Add 1 / 8 to 1 / 3 of the soft monomer, hard monomer, initiator, all emulsifiers and deionized water in the above reactant formula to the reactor, and stir and pre-emulsify at 20°C to 50°C for 15min to 30min , raise the temperature to 75°C-90°C; after initiating the polymerization, add the remaining soft monomers, hard monomers, initiators and cross-linking functional monomers dropwise, and keep warm at 75°C-90°C for 90min-...

Embodiment 2

[0059] Adhesive emulsion polymerization formula (percentage of each component of the reaction system in the total mass of the monomer):

[0060] Hydroxyethyl methacrylate and hydroxypropyl acrylate 1~20

[0061] Ethyl acrylate and butyl acrylate 20~80

[0062] Acrylic 1~10

[0063] Methyl methacrylate 1~10

[0064] Acrylonitrile 0~5

[0065] Acrylamide 0~5

[0066] Potassium persulfate 0.01~0.5

[0067] Sodium dodecylbenzenesulfonate and octylphenol polyethylene glycol ether 2~5

[0068] Appropriate amount of deionized water

[0069] Synthesis:

[0070] Add 1 / 8 to 1 / 3 of the soft monomer, hard monomer, initiator, all emulsifiers and deionized water in the above reactant formula to the reactor, and stir and pre-emulsify at 20°C to 50°C for 15min to 30min , raise the temperature to 75°C-90°C; after initiating the polymerization, add the remaining soft monomers, hard monomers, initiators and cross-linking functional monomers dropwise, and keep warm at 75°C-90°C for 90min-...

Embodiment 3

[0072] Adhesive emulsion polymerization formula (percentage of each component of the reaction system in the total mass of the monomer):

[0073] Hydroxyethyl methacrylate and hydroxybutyl acrylate 1~20

[0074] Butyl acrylate and 2-ethylhexyl acrylate 20~80

[0075] Acrylic acid and methacrylic acid 1~10

[0076] Methyl methacrylate 1~5

[0077] Styrene 0~5

[0078] Acrylamide 0~5

[0079] Ammonium persulfate 0.01~0.5

[0080] Sodium lauryl sulfate and octylphenol polyethylene glycol ether 2~5

[0081] Appropriate amount of deionized water

[0082] Synthesis:

[0083] Add 1 / 8 to 1 / 3 of the soft monomer, hard monomer, initiator, all emulsifiers and deionized water in the above reactant formula to the reactor, and stir and pre-emulsify at 20°C to 50°C for 15min to 30min , raise the temperature to 75°C-90°C; after initiating the polymerization, add the remaining soft monomers, hard monomers, initiators and cross-linking functional monomers dropwise, and keep warm at 75°C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com