A kind of label making technology of plastic container, plastic container and its application

A production process and plastic container technology, applied in the post-processing of printing, printing, printing devices, etc., can solve the problems that the liquid beverage filling production line cannot be used, the printed bottle is connected to the production line, and the production mode is troublesome, so as to achieve beautiful and simple packaging , the cost of environmentally friendly packaging materials, and the effect of meeting safety and health requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

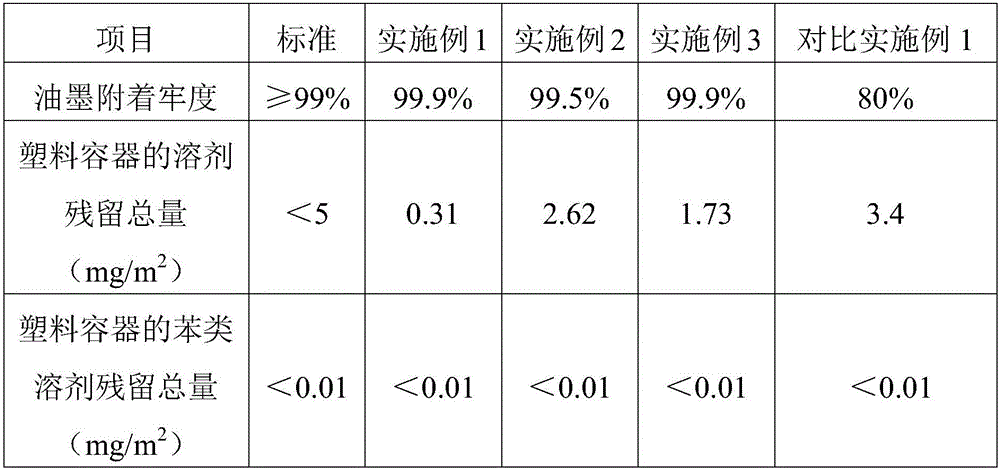

Embodiment 1

[0028] In this embodiment, the label of the round PET bottle is composed of three overlapping colors. The label making process of the PET round bottle includes the following steps: After testing, the surface tension of the PET round bottle is in the range of 44-52dyn / cm, so there is no need to perform surface pretreatment on the PET round bottle. The bottom of the bottle is positioned by the card slot, screen printed, and then instantly cured by ultraviolet light.

[0029] Wherein, the ink for screen printing is JJJJ RC PES-B ink and photoinitiator TPO. The screen stretching tension of the screen printing is 30N / cm; the screen printing screen is a nylon screen plate, and the mesh size of the screen is 350 mesh / inch.

[0030] The label printing process of the PET round bottle is to carry out the label printing process according to the order of the ink color from light color to dark color, that is, first complete the screen printing and UV instantaneous curing of the lightest c...

Embodiment 2

[0032] In this embodiment, the steps and parameters of the label making process of the PET plastic container are the same as in Example 1, the difference is that the PET plastic container is a PET square bottle, and its label is made of three kinds of non-stacking colors. Ink composition; the grid size of the screen printing screen is 420 mesh / inch, and the tension of the screen stretching is 25N / cm; the positioning method is to fix the PET square bottle lying down; the PET square bottle The number of times of the label printing process of the bottle is 1 time, wherein, the power of the ultraviolet light instantaneous curing is 170W / cm.

Embodiment 3

[0034] In the present embodiment, the steps and parameters of the label making process of the PET plastic container are the same as in Example 1, the difference is that the ink of the screen printing is French Dolby's special UV light-curable ink and photoinitiator TPO .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com