A kind of preparation method of neutralizing acid for reactive dye printing washing

A reactive dye and printing technology, which is applied in the field of preparation of neutralizing acid for washing reactive dye printing, can solve the problems affecting the printing fastness and hand feeling of printing and dyeing, cotton fiber strength reduction, acid volatile, etc., to achieve good compatibility and Synergistic effect, high fastness, less residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

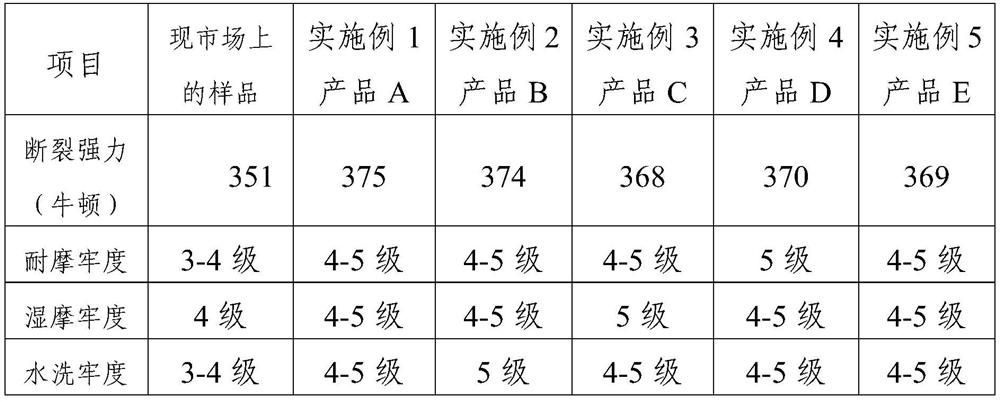

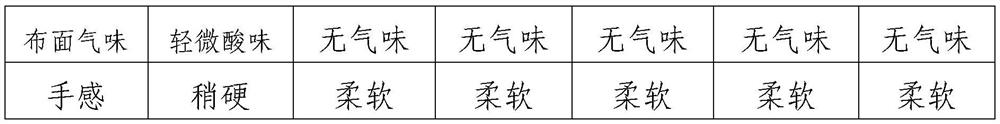

Examples

Embodiment 1

[0026] Step 1, add water 160kg, maleic anhydride 150kg in the reactor, be warming up to 50 ℃, make maleic anhydride dissolve completely, generate maleic acid after water-soluble, add acrylic acid 182kg, itaconic acid 168kg, after stirring, react All the feed liquid in the kettle is poured into the No. 1 dripping tank to obtain the first mixture, which is ready for use;

[0027] Step 2, add water 100kg, sodium persulfate 35kg to No. 2 drip tank, stir until completely dissolved to obtain sodium persulfate aqueous solution A, stand by; add 38-40 water 10kg, sodium persulfate 2kg to the plastic bucket, stir To be completely dissolved, get sodium persulfate aqueous solution B, stand-by;

[0028] Step 3, add water 80kg, the solution 40kg in No. 1 dripping tank, ethanol 80kg in the reactor, stir to be warming up to 78 ℃, add sodium persulfate aqueous solution B, stir and be warming up to 95-97 ℃, react at this temperature 20 minutes;

[0029] Step 4, control the temperature of the ...

Embodiment 2

[0032] Step 1, add water 162kg, maleic anhydride 151kg in the reactor, be warming up to 52 ℃, make maleic anhydride dissolve completely, generate maleic acid after water-soluble, add acrylic acid 183kg, itaconic acid 169kg, after stirring, by reaction All the feed liquid in the kettle is poured into the No. 1 dripping tank to obtain the first mixture, which is ready for use;

[0033] Step 2, add water 104kg, sodium persulfate 36kg to No. 2 drip tank, stir until completely dissolved to obtain sodium persulfate aqueous solution A, stand by; add water 12kg, sodium persulfate 3kg to the plastic bucket, stir until completely dissolved Obtain sodium persulfate aqueous solution B, stand-by;

[0034] Step 3, add water 85kg, the solution 41kg in No. 1 dripping tank, ethanol 85kg in the reactor, stir to be warming up to 79 ℃, add sodium persulfate aqueous solution B, stir and be warming up to 95-97 ℃, react at this temperature 21 minutes;

[0035] Step 4, control the temperature of th...

Embodiment 3

[0038] Step 1, add water 166kg, maleic anhydride 153kg in the reaction kettle, be warming up to 53 ℃, make maleic anhydride dissolve completely, generate maleic acid after water-soluble, add acrylic acid 186kg, itaconic acid 171kg, after stirring, by reaction All the feed liquid in the kettle is poured into the No. 1 dripping tank to obtain the first mixture, which is ready for use;

[0039] Step 2, add 112kg of water and 38kg of sodium persulfate to the No. 2 drip tank, stir until completely dissolved to obtain an aqueous solution of sodium persulfate A, for use; add 16kg of water and 4.5kg of sodium persulfate to the plastic bucket, and stir until completely Dissolved to obtain aqueous sodium persulfate solution B, for use;

[0040] Step 3, add water 90kg, the solution 43kg in No. 1 dripping tank, 91kg of ethanol in the reactor, stir to be warming up to 79 ℃, add sodium persulfate aqueous solution B, stir and be warming up to 95-97 ℃, react at this temperature 23 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com