Method for preparing ultra macropore type rigid macromolecule medium by using suspension liquid of fine particles of calcium carbonate

A calcium carbonate, suspension technology, applied in chemical instruments and methods, material separation, analysis of materials, etc., can solve problems such as reduced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

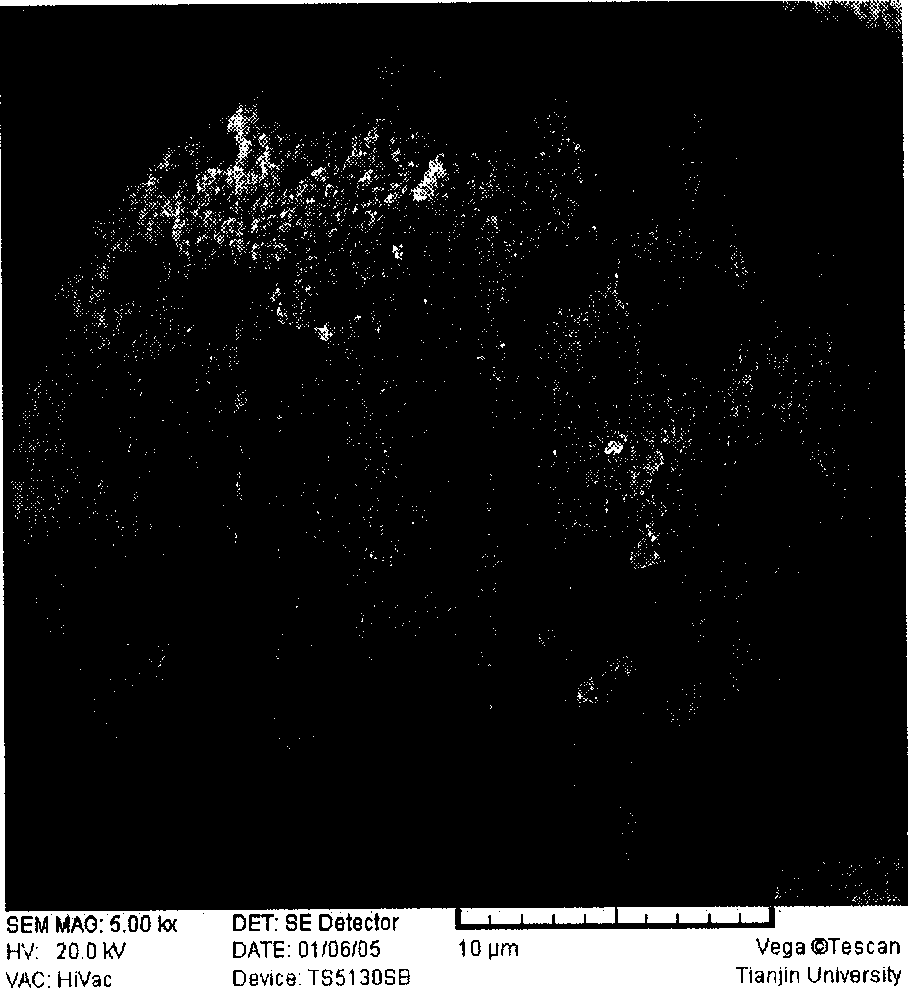

Image

Examples

Embodiment 1

[0022] Weigh 10 grams of nano-scale calcium carbonate powder, add it to 50 mL of 1% Triton 114 solution, shake it for 10 minutes, then mix it in an ultrasonic water bath for 30 minutes, then centrifuge it at 8000rpm for 10 minutes, pour off the supernatant before adding Distilled water, and then centrifuged, so repeated several times until Triton 114 is removed, and then set the volume to 50mL, you can get 20% calcium carbonate suspension.

[0023] Weigh 0.08 g of benzoin ether and 1.2 g of Span 80 and dissolve them in 4.5 mL of glycidyl methacrylate (GMA) and 3.0 mL of ethylene glycol dimethacrylate (EDMA); then add 2.5 mL of cyclohexanol and 1 mL of lauryl alcohol and mix well. Add 8mL of 20% calcium carbonate suspension to the mixed solution, stir for 5 minutes at 8000rpm, the small droplets formed by its emulsification can be clearly seen under the microscope, then add the stirred emulsion to 120mL of 2% In the PVA aqueous solution, stir at 1800 rpm for 1 minute, then tra...

Embodiment 2

[0025] Weigh 3.8 grams of calcium hydroxide solid powder, dissolve in sufficient water to obtain a clear calcium hydroxide solution, add the obtained calcium hydroxide solution into a three-neck reactor with a stirring paddle, and stir at a high speed While feeding carbon dioxide gas, stop feeding when the turbidity of the reaction no longer increases, then centrifuge to get the supernatant and use a clear calcium hydroxide solution to check whether the supernatant still contains calcium bicarbonate, if not, you can remove the supernatant. Clear liquid, resuspend the precipitate and adjust the volume to 50mL to obtain a 10% calcium carbonate suspension.

[0026] Weigh 0.08 g of benzoin ether and 1.5 g of Span 80 and dissolve them in 4.5 mL of glycidyl methacrylate (GMA), 3.0 mL of ethylene glycol dimethacrylate (EDMA); then add 3 mL of toluene and 2 mL of n-heptane to mix uniform. Add 4.5mL of 10% calcium carbonate suspension to the mixture, stir at 8000rpm for 5 minutes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com