Cross-linked quaternary phosphonium ionic liquid and preparation thereof and application in CO2 cycloaddition reaction

An ionic liquid and quaternary phosphonium salt technology, applied in the field of industrial catalysis, can solve problems such as being unsuitable for industrial production, and achieve the effects of being suitable for large-scale production, low cost, high selectivity and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

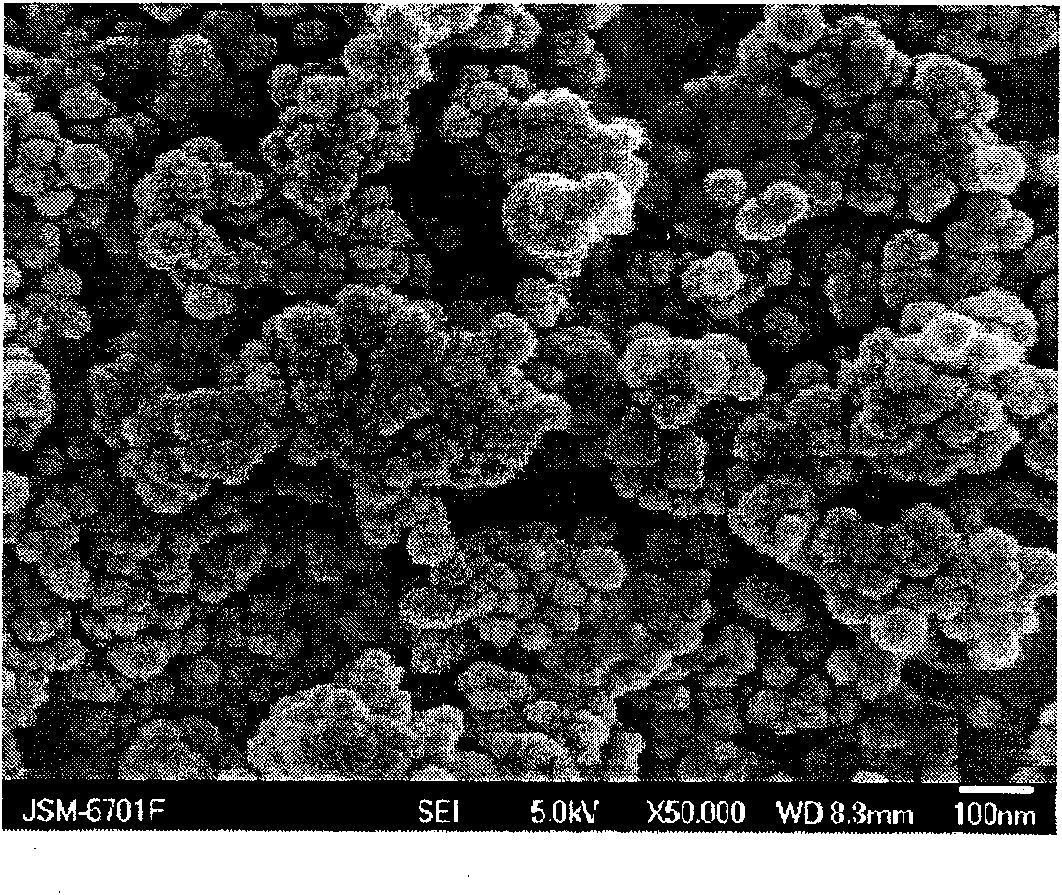

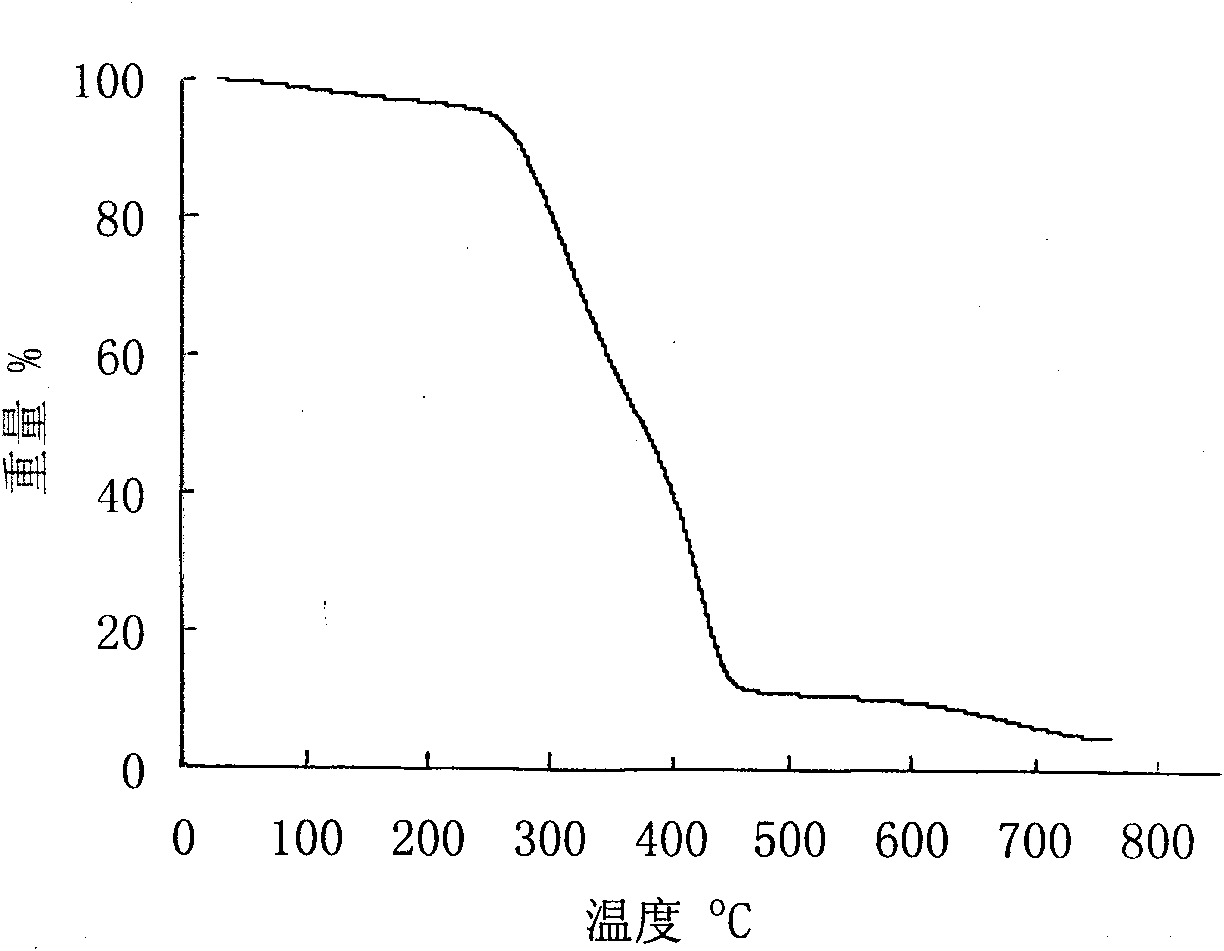

[0034] Embodiment 1, preparation of crosslinked quaternary phosphonium salt ionic liquid catalyst

[0035] 1. Raw materials

[0036] Triphenylphosphine is chemically pure, purchased from Sinopharm Chemical Reagent Co., Ltd.;

[0037] 4-vinylbenzyl chloride was purchased from Alfa Aesar;

[0038] Ethylene glycol dimethacrylate was purchased from Shanghai Jingchun Reagent Co., Ltd.;

[0039] Azobisisobutyronitrile is analytically pure.

[0040] Neptone and tetrahydrofuran were of analytical grade, purchased from Sinopharm Chemical Reagent Co., Ltd., and used directly without treatment.

[0041] 2. Process

[0042] (1) Synthesis of quaternary phosphonium salt ionic liquid

[0043] Mix 0.1 mol of 4-vinylbenzyl chloride and 0.1 mol of triphenylphosphine, heat to 50°C, and react for 24 hours to obtain a quaternary phosphine salt ionic liquid. Yield: 82%.

[0044] (2) Preparation of crosslinked quaternary phosphonium salt ionic liquid

[0045] Mix 1g of ethylene glycol dimeth...

Embodiment 2

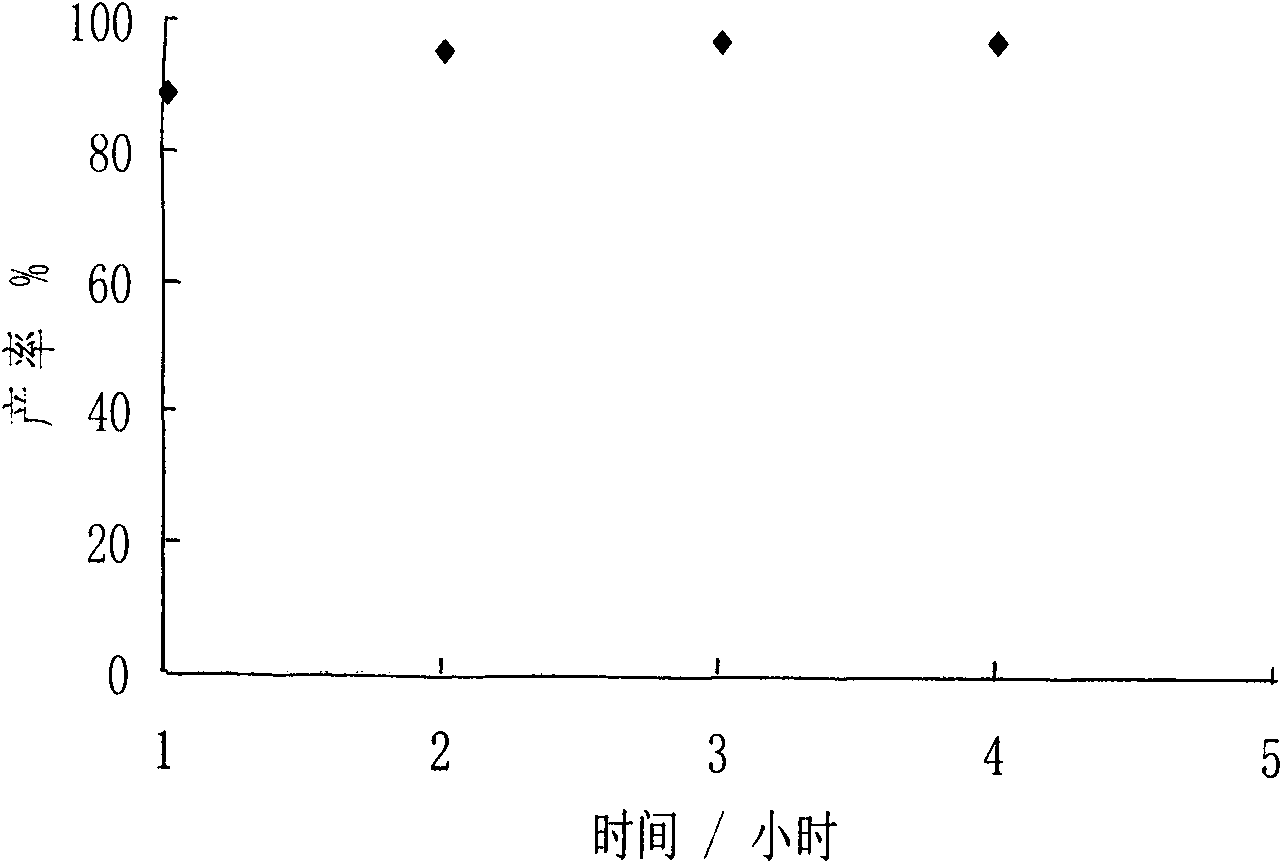

[0053] Example 2. Application of cross-linked quaternary phosphonium salt ionic liquid in carbon dioxide cycloaddition reaction

[0054] Add 3mL of epichlorohydrin, a magneton, and 0.1g of the catalyst prepared in this paper into a 100mL stainless steel autoclave, and place it at 160°C and a pressure of 5Mpa after replacing the air. The reaction was stirred for 2 hours. After the reaction is over, cool down, release gas, and filter the mixture to obtain the corresponding cyclic carbonate. The yield reached 99.2%. Its selectivity is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com