Silicone-hydrogel compound for soft contact lens and soft contact lens produced using the compound

A technology of soft contact lenses and silicon hydrogel, which is applied in the direction of eye implants, intraocular lenses, instruments, etc., can solve the problems of poor ductility and poor recovery ability, achieve good light transmittance, and solve the problem of wear and tear. Effect of extirpation, reduction of corneal edema and other diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

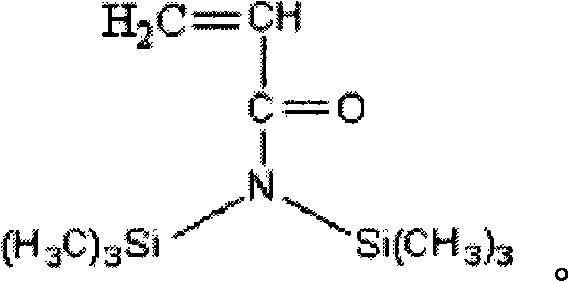

[0040] Polymerization of N,O-bis(trimethylsilyl)acrylamide and 2-hydroxyethyl methacrylate

[0041] N, the amount of O-two (trimethylsilyl) acrylamide increases from 10g to 90g, every time increases 10g, the amount of 2-hydroxyethyl methacrylate reduces from 90g to 10g, every time reduces 10g, by This makes a mixture. 0.1-1 g of the initiator 2,5-dimethyl-2,5-bis(peroxy-2-ethylhexanoyl)hexane was dissolved to polymerize the mixture at 110° C. for 30 minutes.

[0042] The results showed that when 0.2 g (0.2% by weight) of the initiator and the above-mentioned substances were used, polymerization occurred regardless of the content of the initiator, but the initiator was independent of the transparency (compatibility). When more than 10 g (10% by weight) of N,O-bis(trimethylsilyl)acrylamide was used, the mixture solidified but was less compatible and became opaque milk color. The more N, O-bis(trimethylsilyl)acrylamide is used, the less likely it is to cure. In this way, the p...

Embodiment 2

[0045] Polymerization of N,O-bis(trimethylsilyl)acrylamide and N-vinyl-2-pyrrolidone

[0046] N, the amount of O-two (trimethylsilyl) acrylamide increases from 10g to 90g, every time increases 10g, the amount of N-vinyl-2-pyrrolidone decreases from 90g to 10g, every time reduces 10g, by This makes a mixture. 0.1-1 g of the initiator 2,5-dimethyl-2,5-bis(peroxy-2-ethylhexanoyl)hexane was dissolved to polymerize the mixture at 110° C. for 30 minutes.

[0047] The results showed that the mixture did not cure regardless of the amount of initiator used. The higher the amount of N,O-bis(trimethylsilyl)acrylamide used, the less likely curing will occur. This way, even though when polymerized, the mixture is as viscous as an adhesive, the mixture does not cure.

[0048] In the polymerization of this example, even if N,O-bis(trimethylsilyl)acrylamide and the water-soluble monomer N-vinyl-2-pyrrolidone were polymerized, the polymer did not cure. Such mixtures are not suitable for co...

Embodiment 3

[0050] Polymerization of N,O-bis(trimethylsilyl)acrylamide, 2-hydroxyethyl methacrylate and ethylene glycol dimethacrylate

[0051] N, the amount of O-two (trimethylsilyl) acrylamide increases from 10g to 90g, every time increases 5g, the amount of 2-hydroxyethyl methacrylate reduces from 90g to 50g, every time reduces 5g, again 0.1-1 g of crosslinker ethylene glycol dimethacrylate was added to the mixture. 0.2 g of the initiator 2,5-dimethyl-2,5-bis(peroxy-2-ethylhexanoyl)hexane was dissolved, and the mixture was polymerized at 110° C. for 30 minutes.

[0052] The results showed that with the increase of the amount of ethylene glycol dimethacrylate, the transparency (compatibility) and curing ability of the polymer increased, but the ductility became worse. In order to make the polymer suitable for making contact lenses, it is necessary to add ethylene glycol dimethacrylate in an amount of 0.5 g (less than 0.5% by weight). When the amount of N, O-bis(trimethylsilyl)acrylami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com