Preparation and application of fluorescence ion imprinting probe

A fluorescent ion and fluorescent probe technology, applied in the field of fluorescent ion imprinted probe preparation, can solve the problems of limited application, inability to use complex system detection, low selectivity, etc., and achieve high sensitivity, excellent recognition performance, and improved sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) EuCl 3 0.5 mmol, 0.75 mmol of phen, and 0.5 mmol of TTA were dissolved in 100 mL of ethanol with magnetic stirring, and concentrated ammonia water was added dropwise after five minutes. Adjust pH=7, the solution becomes turbid. Continue stirring for 2 h, centrifuge, and wash three times with ethanol. get Dy( ) complexes.

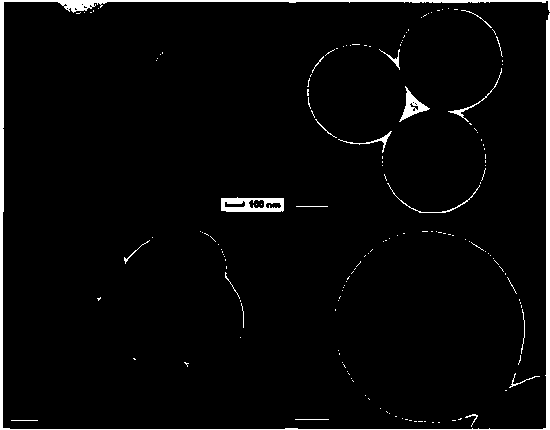

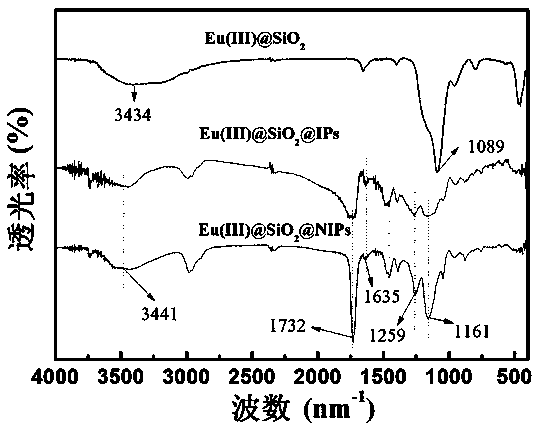

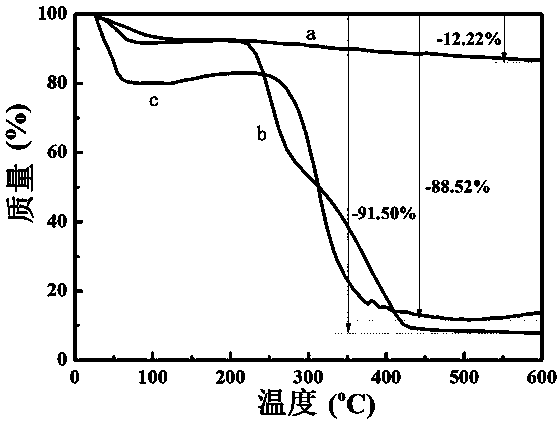

[0041] (2) Eu( in step (1) ) complex 100 mg was dissolved in 5 mL DMF. Form solution A with a mixed solution of 25 ml ethanol and 1 mL TEOS. Then 1 mL of ammonia water was added to the mixed solution of 14 ml of ethanol and 5 ml of distilled water to form solution B, then solution A was quickly poured into solution B, and magnetically stirred for 2 h. centrifuged and washed three times to obtain Eu(III)SiO 2 .

[0042] (3) Eu(III)SiO obtained in (2) 2 Disperse 0.1 g in 30 mL of acetonitrile, then add 0.35 mmol methacrylic acid (MAA), 1.50 mL ethylene glycol dimethacrylate (EGDMA), 0.10 mmol Cu 2+ . N 2 Under protection, self-assem...

Embodiment 2

[0049] (1) EuCl 3 0.5 mmol, phen 0.5 mmol, and TTA 0.5 mmol were dissolved in 100 mL of ethanol with magnetic stirring, and concentrated ammonia water was added dropwise after five minutes. Adjust pH=7, the solution becomes turbid. Continue stirring for 2 h, centrifuge, and wash three times with ethanol. get Dy( ) complexes.

[0050] (2) Eu( ) complex 20 mg was dissolved in 1 mL DMF. Form solution A with a mixed solution of 5 ml ethanol and 0.19 mL TEOS. Then 0.2 mL of ammonia water was added to the mixed solution of 4.2 ml of ethanol and 1.5 ml of distilled water to form solution B, then solution A was quickly poured into solution B, and magnetically stirred for 2 h. centrifuged and washed three times to obtain Eu(III)SiO 2 .

[0051] (3) Disperse 0.12 g of the fluorescent material obtained in (2) in 30 mL of acetonitrile, then add 0.50 mmol methacrylic acid (MAA), 1.55 mL ethylene glycol dimethacrylate (EGDMA), 0.12 mmol Cu 2+ . N 2 Under protection, self-assem...

Embodiment 3

[0055] (1) EuCl 3 0.5 mmol, 0.5 mmol of phen, and 0.5 mmol of TTA were dissolved in 100 mL of ethanol with magnetic stirring, and concentrated ammonia water was added dropwise after five minutes. Adjust pH=7, the solution becomes turbid. Continue stirring for 2 h, centrifuge, and wash three times with ethanol. get Dy( ) complexes.

[0056] (2) Eu( in step (1) ) complex 50 mg was dissolved in 2 mL DMF. The mixed solution with 10ml ethanol and 0.5 mL TEOS forms solution A. Then 0.4 mL of ammonia water was added to the mixed solution of 7 ml of ethanol and 2.5 ml of distilled water to form solution B, then solution A was quickly poured into solution B, and magnetically stirred for 2 h. centrifuged and washed three times to obtain Eu(III)SiO 2 .

[0057] (3) Disperse 0.12 g of the fluorescent material obtained in (2) in 30 mL of acetonitrile, then add 0.60 mmol methacrylic acid (MAA), 1.70 mL ethylene glycol dimethacrylate (EGDMA), 0.15 mmol Cu 2+ . N 2 Under protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com