Preparation method of pH responsive cation nanogel

A nanogel and cation technology, applied in the field of preparation of cationic nanogels, can solve the problems of low charge density, weak pH response of microgels, limited application range, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

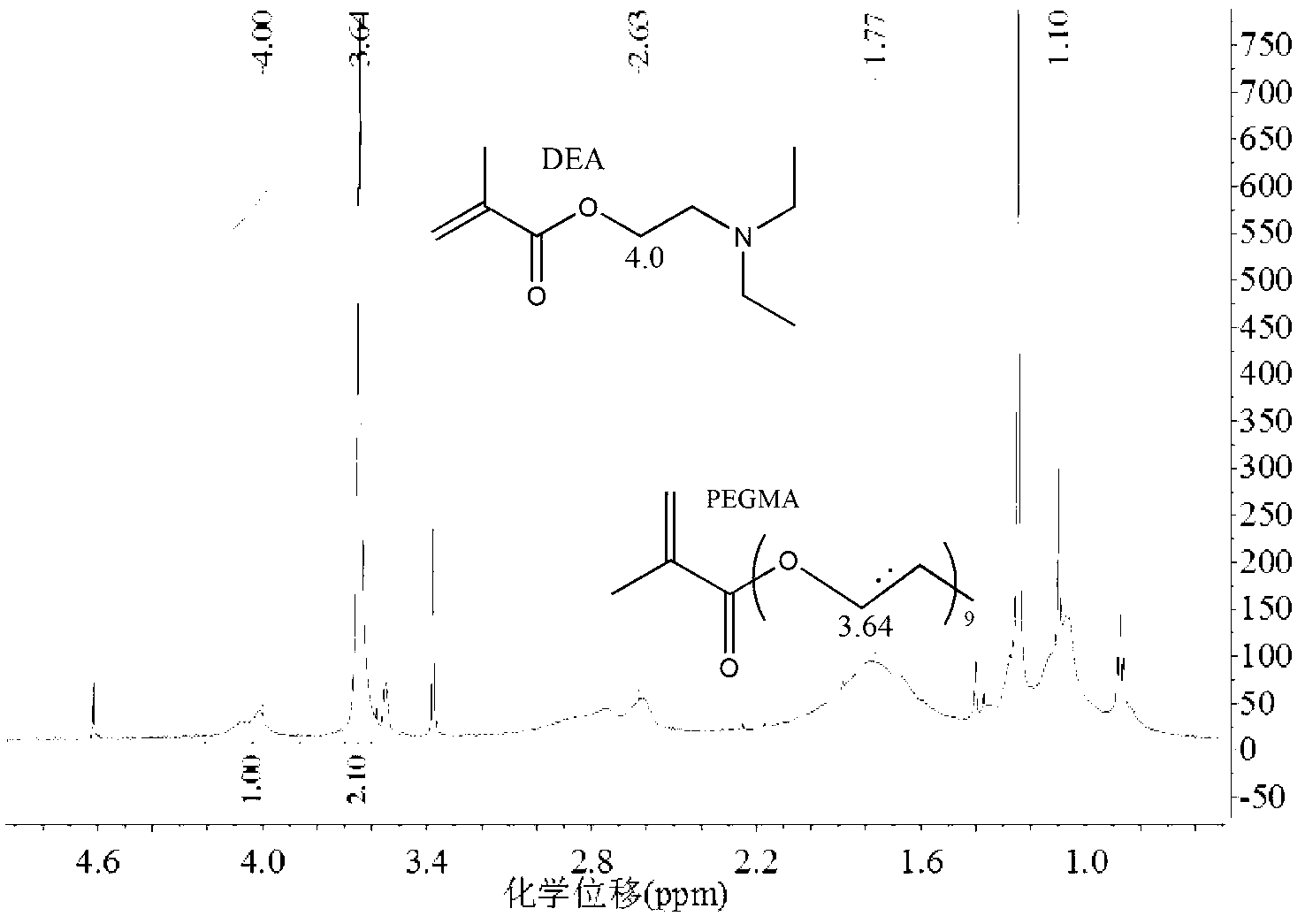

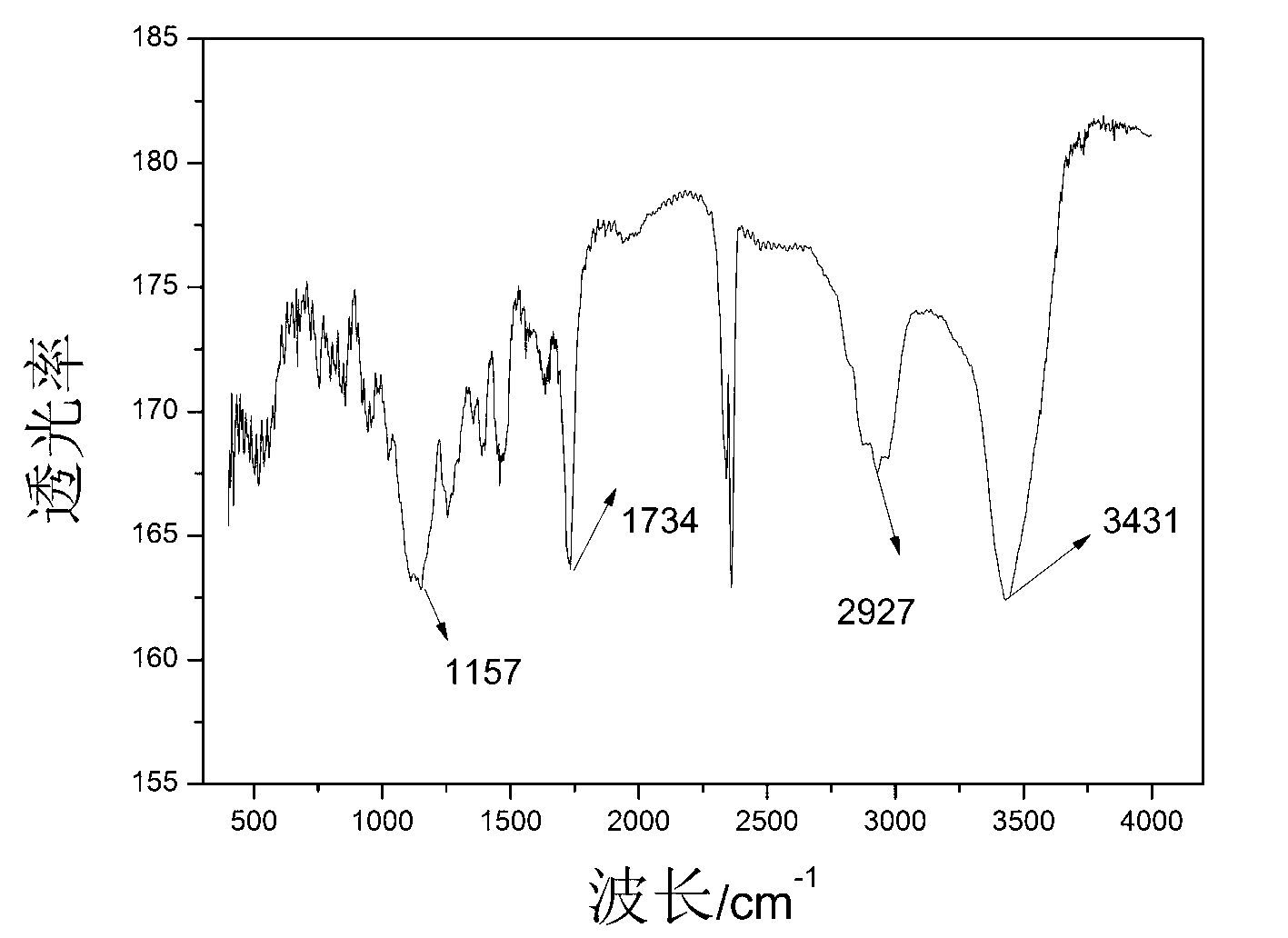

[0025] Weigh 0.15g of SDS into 45mL of water, sonicate for 10min to fully dissolve, add to a 100mL four-necked flask, add 0.35g of a stabilizer PEGMA with a relative molecular weight of 2000, blow in nitrogen, stir and pre-emulsify for 30min to obtain an aqueous phase solution.

[0026] Weigh 0.05g EGDMA, mix it with 5g DEA in a small flask, and ultrasonically mix it evenly to obtain a monomer mixture, add it to a constant pressure dropping funnel, and drop it into the water in a four-necked flask at a speed of 0.03mL / min. phase solution, stirred for 2 to 3 hours to obtain a microemulsion.

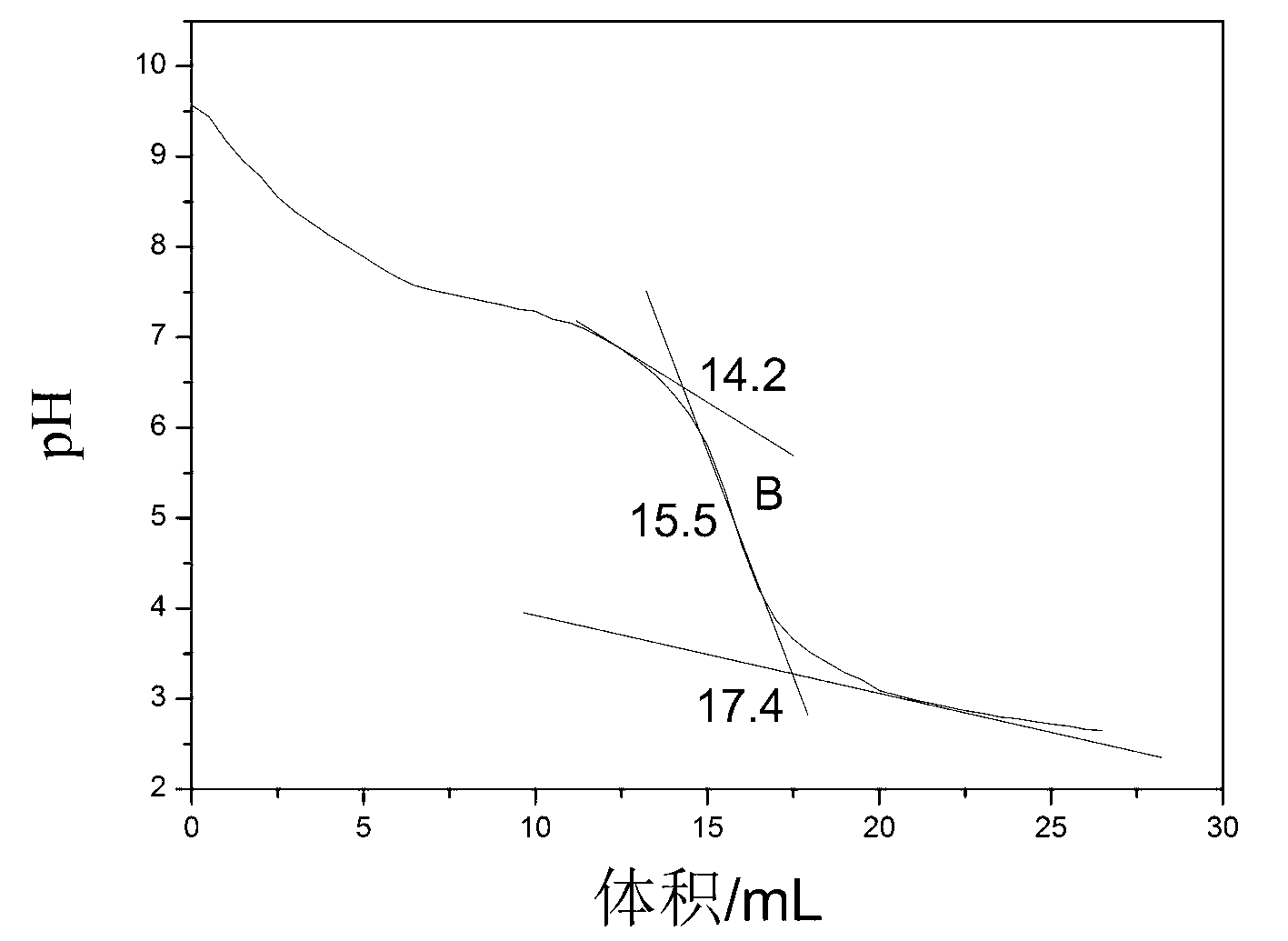

[0027] The temperature of the microemulsion was raised to 65°C and stabilized for 10 minutes. Mix 0.05 g of initiator V-50 and 5 mL of water into a constant-pressure funnel, and dropwise added to the microemulsion at an average speed of 0.25 mL / min. After the dropwise addition, react for 20 hours to generate a white PDEA nanogel emulsion with bluish light. Placed in deionized water and di...

Embodiment 2

[0034] Weigh 0.07g of SDS and add it into 45mL of water, sonicate for 10min to fully dissolve it, add it into a 100mL four-necked flask, add 0.15g of a stabilizer PEGMA with a relative molecular weight of 2000, blow in nitrogen, stir and pre-emulsify for 30min to obtain an aqueous phase solution.

[0035] Weigh 0.02g EGDMA, mix it with 3g DPA in a small flask, and ultrasonically mix it evenly to obtain a monomer mixture, add it to a constant pressure dropping funnel, and drop it into the water in a four-necked flask at a speed of 0.03mL / min. phase solution, stirred for 2 to 3 hours to obtain a microemulsion.

[0036] The temperature of the microemulsion was raised to 65°C and stabilized for 10 min. Mix 0.015 g of initiator V-50 and 5 mL of water into a constant pressure funnel, and drop into the microemulsion at an average speed of 0.25 mL / min. After the dropwise addition, react for 20 hours to generate a white emulsion of PDPA nanogel with bluish light. Placed in deionized w...

Embodiment 3

[0038] Weigh 0.06g EGDMA and put it into a small flask, mix it with 5g DEA, and ultrasonically mix it evenly. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com