Method and used catalytic agent for synthesizing N-butylethylamine

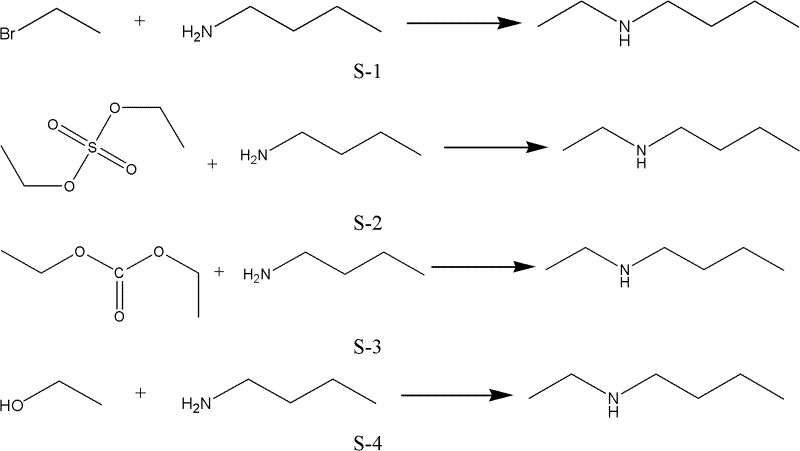

A technology of ethyl n-butylamine and catalyst, which is applied in the field of synthesis of chemical intermediate-N-ethyl n-butylamine, can solve problems such as heavy burden and reduced catalyst activity, achieve cost reduction, reduce the burden of separation, and reduce the price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, the preparation method of supported catalyst, carry out following steps successively:

[0047] 1), initial roasting:

[0048] Gamma-alumina (γ-Al 2 o 3 ) at 430-470°C for 3 hours, and then at 600-650°C for 6 hours; 2 o 3 .

[0049] After testing: the specific surface area of the γ-alumina after roasting is 200-220m 2 g -1 , the pore diameter is 13.5-14.0nm, and the particle diameter remains unchanged.

[0050] 2), the roasted γ-Al obtained in step 1)2 o 3 Immerse in water for 36 hours, and then measure the volume of water reduction, so as to obtain the γ-Al after calcination 2 o 3 The pore volume density is 0.83ml / g.

[0051] 3), initial impregnation:

[0052] 47.4g of copper nitrate trihydrate and 63.3g of solid nickel nitrate hexahydrate (the molar ratio of copper and nickel elements is 0.9:1) were adjusted to 118mL with water (for example, distilled water) to obtain a mixed solution;

[0053] After step 1) the obtained γ-Al after roasting ...

Embodiment 2

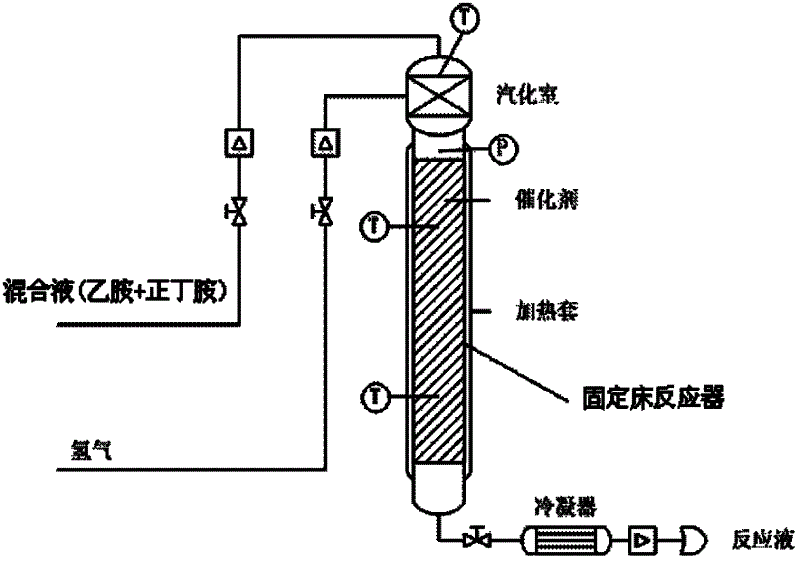

[0061] Embodiment 2, a kind of synthetic method of N-ethyl n-butylamine, carry out following steps successively:

[0062] 1), the prepared supported catalyst (gained in Example 1) is activated:

[0063] ①. Initially activate the supported catalyst first. During the initial activation, the aeration time, aeration flow rate and heating temperature in different activation time periods are shown in Table 1 above; this step can be carried out outside the fixed bed reactor, and can also be used Fixed bed reactor (but need to add N 2 connecting pipes).

[0064] ②. Load the initially activated supported catalyst into a fixed-bed reactor, and reactivate it at 160-250°C (for example, 240°C) under the action of hydrogen until the activation is completed (that is, there is no condensed water in the lower part of the fixed-bed reactor) produced); the activated supported catalyst was obtained.

[0065] 2), 730g (16.2mol) of ethylamine and 580g (7.95mol) of n-butylamine are mixed and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com