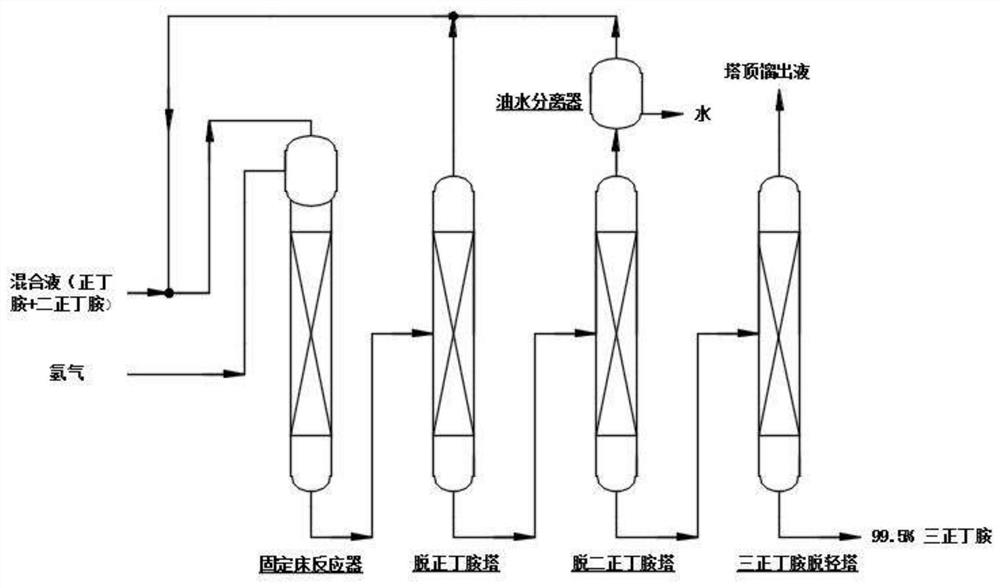

High-purity tri-n-butylamine production method and device used

A technology of tri-n-butylamine and production equipment, which is applied in the fields of purification/separation of amino compounds, organic chemistry, and disproportionation to prepare amino compounds. The effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

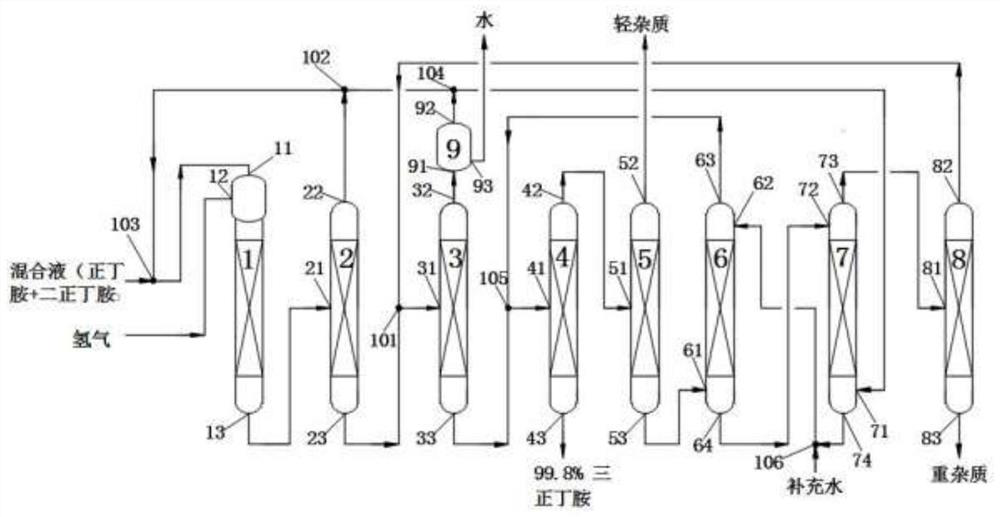

[0029] Example 1, a kind of high-purity tri-n-butylamine production device, by fixed bed reactor 1, removing n-butylamine tower 2, removing di-n-butylamine tower 3, removing light tower 4, molecular distillation tower 5, extraction tower 6, The stripping tower 7, the extractant regeneration tower 8 and the oil-water separator 9 are formed;

[0030] The upper part of the fixed-bed reactor 1 is a vaporization chamber, and the lower part is a fixed-bed reaction section. The vaporization chamber is provided with a material inlet 11 and a hydrogen inlet 12; the bottom of the fixed-bed reaction section is provided with a bottom outlet 13;

[0031]The removal of n-butylamine tower 2, the removal of di-n-butylamine tower 3, the removal of light tower 4, and the extraction agent regeneration tower 8 are all rectification towers, and are all provided with a feed inlet, a tower top distillate liquid outlet and a tower still liquid outlet; Specifically:

[0032] The de-n-butylamine tower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com