Catalyst for producing polyethylene polyamine, application of catalyst and preparation method of polyethylene polyamine

A polyvinylpolyamine and catalyst technology, which is applied in chemical instruments and methods, disproportionate preparation of amino compounds, heterogeneous catalyst chemical elements, etc., can solve the problem of low diethylenetriamine/piperazine ratio, producing more piperazine, problems such as low economic value, to achieve the effect of excellent performance, less content and high proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

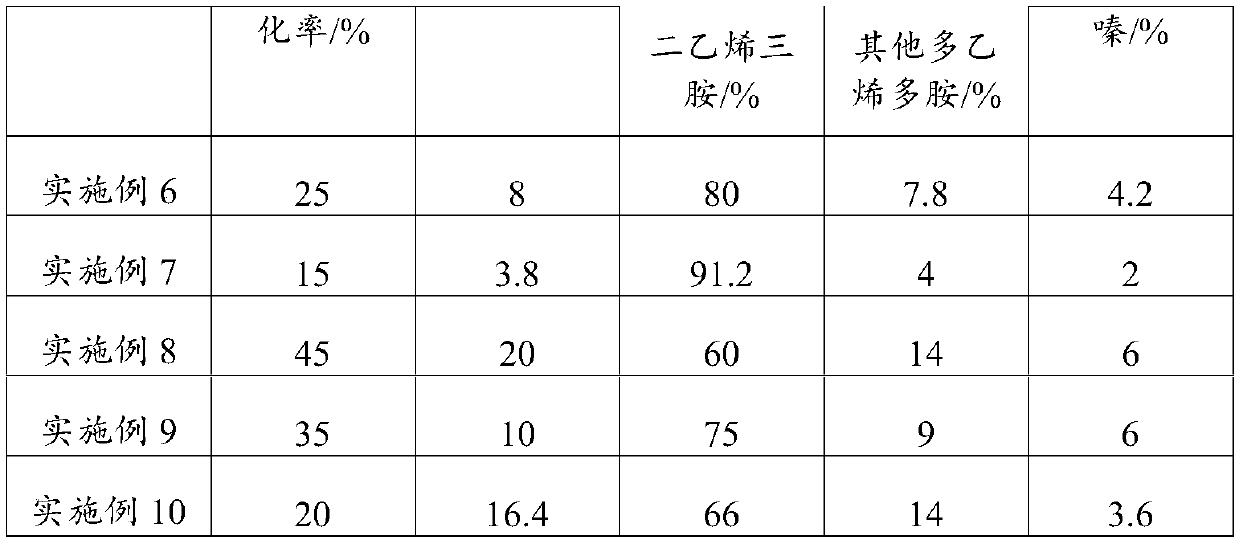

Examples

preparation example Construction

[0047] In a third aspect, the present invention provides a method for preparing polyethylene polyamine, comprising the following steps:

[0048]Provide C1-C6 amine substances as reaction raw materials, the amine substances are fed with hydrogen under the condition of heating and pressure, and a catalytic reaction occurs under the catalysis of the catalyst of the present invention, and the polyethylene is obtained after the reaction Polyamines.

[0049] C1-C6 amine substances are used as reaction raw materials, and the catalyst provided by the invention is used to catalyze the reaction, so that the amino groups in the amine substances are transferred, thereby preparing polyethylene polyamines. The preparation method of polyethylene polyamine provided by the invention has the advantage of high yield of diethylene triamine / piperazine.

[0050] Wherein, the amines include but are not limited to at least one of ethylenediamine, diethylenetriamine, triethylenetetramine or aminoethy...

Embodiment 1

[0056] This example is a catalyst for the production of polyethylene polyamines, consisting of 30% NiO-30% CoO-10% CuO-30% Al 2 o 3 .

[0057] The preparation method of this catalyst comprises the following steps:

[0058] S1) Add water to 6.04g copper nitrate trihydrate, 23.28g cobalt nitrate hexahydrate, 23.28g nickel nitrate hexahydrate and 44.12g aluminum nitrate nonahydrate to 200g to obtain a solution containing metal elements;

[0059] S2) prepare a certain amount of 20wt%Na 2 CO 3 alkaline solution;

[0060] S3) Add the solution in step S1) and the alkali solution in step S2) at 70°C and mechanical stirring at a certain ratio and mix at a constant speed, keep the pH of the precipitation process = 7, age for 2 hours after precipitation, wash with water, pump The filter cake was obtained by filtration and drying, calcined at 500°C for 4 hours, and the catalyst was obtained after tableting and granulation.

Embodiment 2

[0062] This example is a catalyst for producing polyethylene polyamine, which is composed of 5% Ni-10% Co-1.5% Ru-1.2% B-silicon-aluminum composite oxide carrier.

[0063] The preparation method of this catalyst comprises the following steps:

[0064] Take by weighing 5g processed silicon-aluminum composite oxide as catalyst carrier, 1.24g nickel nitrate hexahydrate, 2.47g cobalt nitrate hexahydrate, 2.3ml ethylenediamine and 0.15g ruthenium chloride, 0.34 boric acid are dissolved in 10ml water, in Dissolve at 50°C, add half of the impregnation solution evenly to the catalyst carrier, dry at room temperature, dry in an oven at 120°C for 4 hours, and then bake in a muffle furnace at 550°C for 4 hours; repeat the above preparation process until the required loading capacity is reached, and get catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com