Method for preparing grapheme-titanium dioxide composite electrochemical biosensor

A biosensor, titanium dioxide technology, applied in the direction of electrochemical variables of materials, scientific instruments, instruments, etc., can solve the problems of limited application and poor conductivity of electrochemical biosensors, and achieve simple process methods, low detection limits, and biological affinity. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

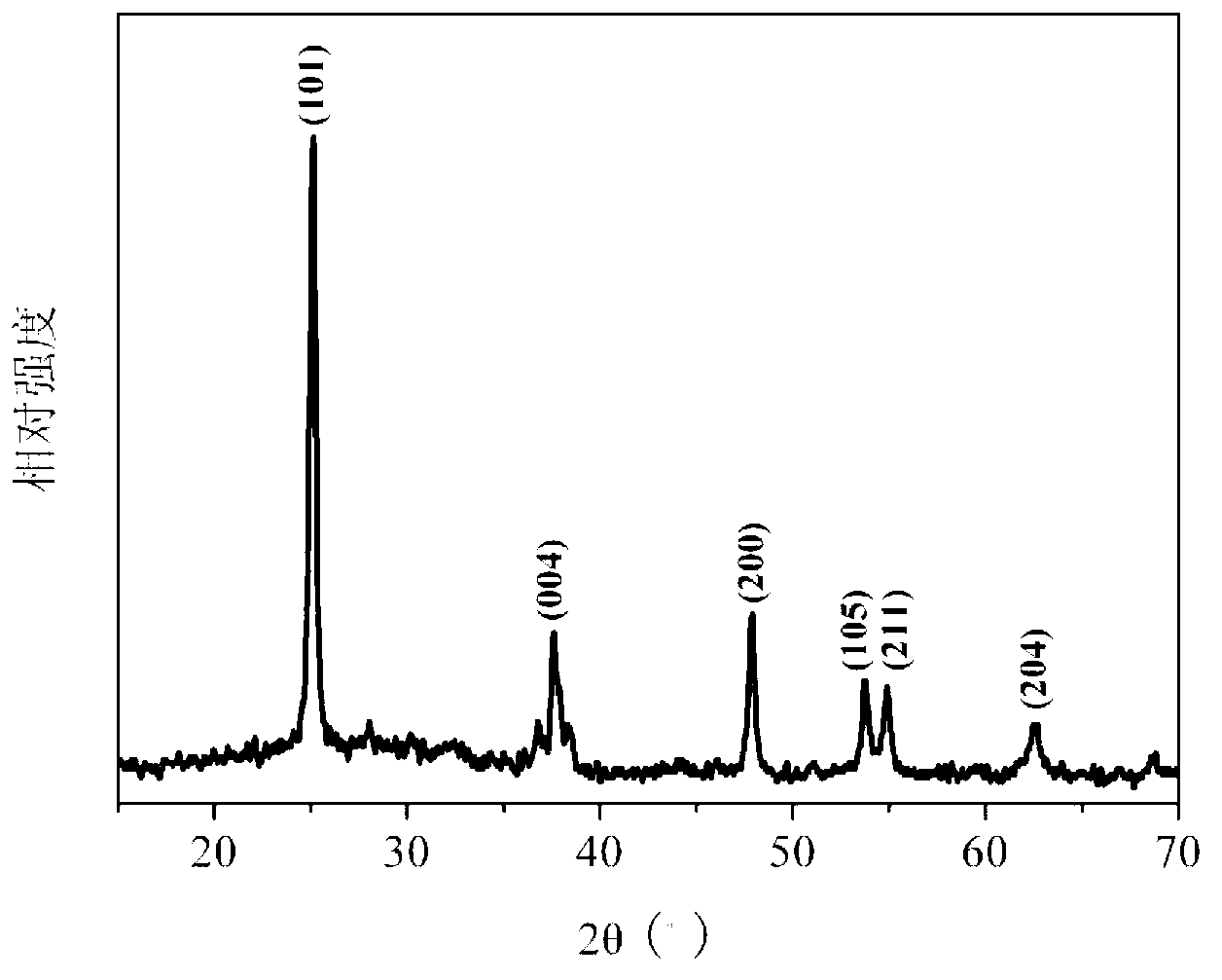

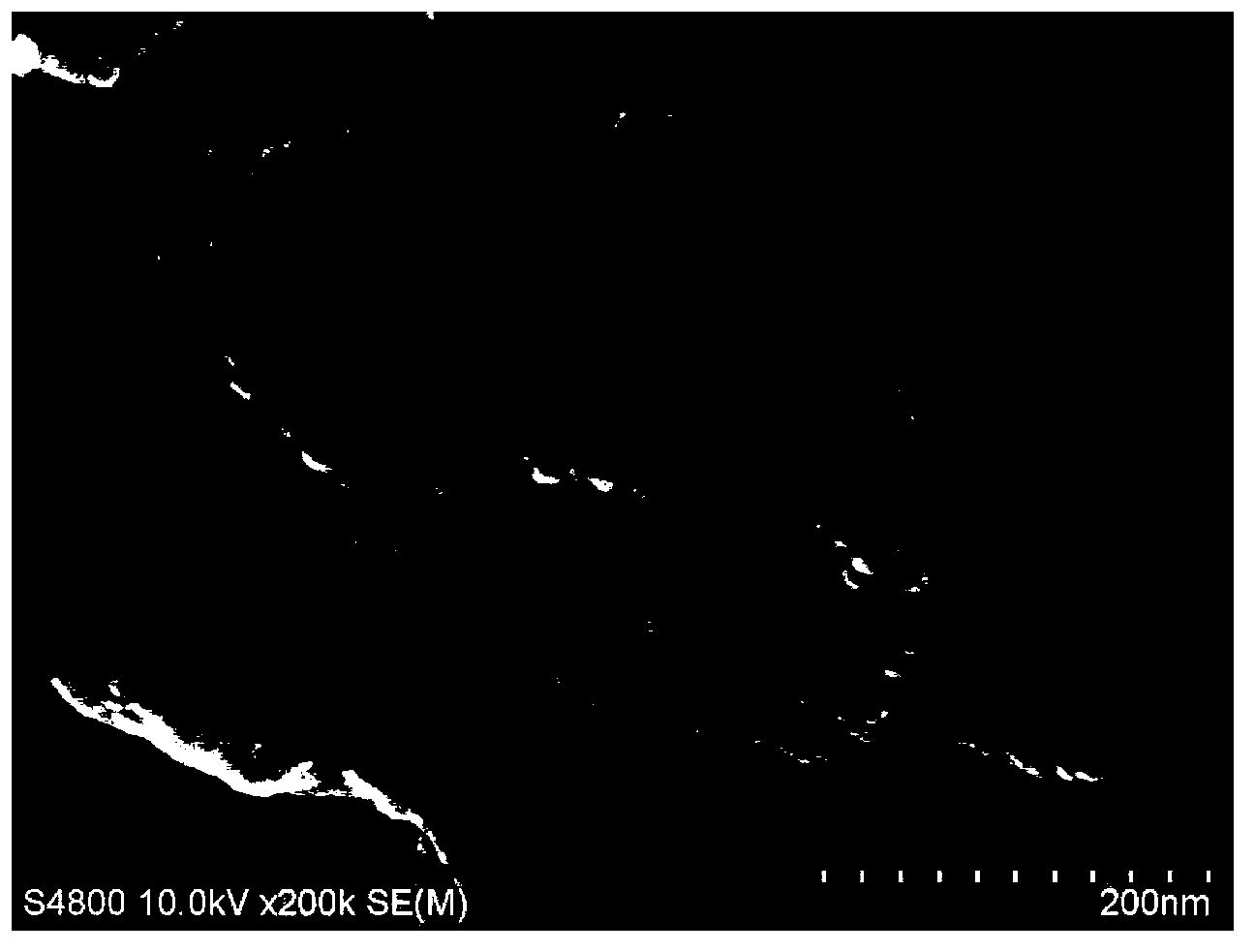

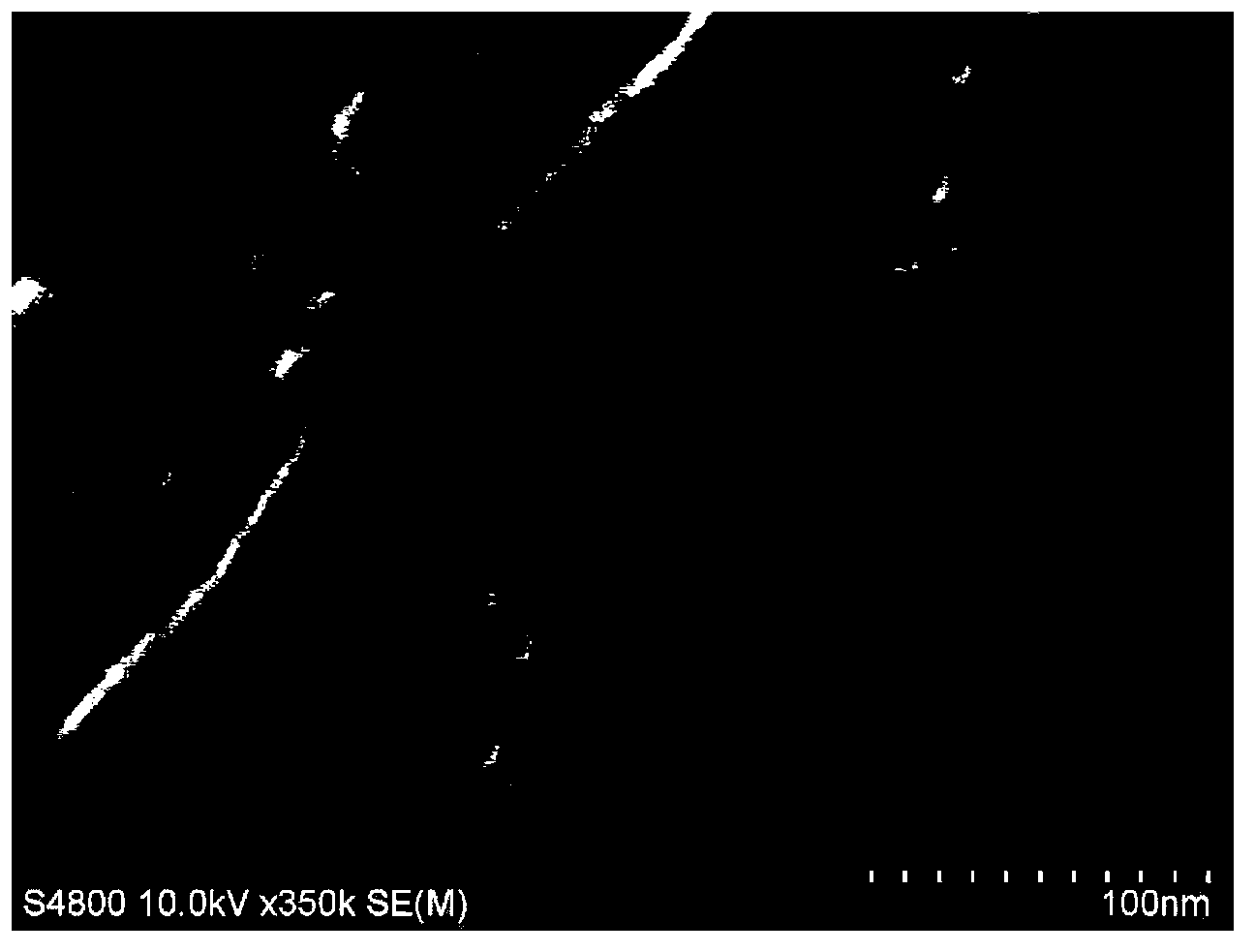

[0043] Graphene oxide was prepared by the improved Hummers method. Take 1 g of pre-prepared graphite oxide, disperse it in 40 mL of deionized water, and ultrasonicate for 3 h. After centrifugation, the supernatant was taken to obtain graphene oxide. Take 200-400mL of absolute ethanol, add 0.5-2.0mL of potassium chloride solution with a concentration of 0.4mmol / L, stir for 10-30min, add a certain amount of graphene oxide powder, stir for a certain period of time, slowly drop in 3-6mL of Butyl titanate was stirred for 10 minutes, aged for 3-6 hours, washed by centrifugation, dried, and placed in an argon atmosphere furnace. The heating rate is 2°C / min before 300°C. When between 300°C and 500°C, the heating rate is 1°C / min. Insulate at 500°C for 2h. A graphene-supported titanium dioxide composite material was obtained.

[0044] Polish the glassy carbon electrode with 1.0, 0.3, and 0.05 μm alumina powder in turn, then ultrasonically clean the electrode surface with deionized w...

Embodiment 2

[0048] Graphene oxide was prepared by the improved Hummers method. Take 1 g of pre-prepared graphite oxide, disperse it in 40 mL of deionized water, and ultrasonicate for 3 h. After centrifugation, the supernatant was taken to obtain graphene oxide. Take 200-400mL of absolute ethanol, add 0.5-2.0mL of sodium chloride solution with a concentration of 1mmol / L, stir for 10-30min, add a certain amount of graphene oxide powder, stir for a certain period of time, slowly drop in 3-6mL of titanium Acetyl butyl ester, stirred for 10min. Aging 3-6h. Washed by centrifugation, dried, and placed in an argon atmosphere furnace. The heating rate is 2°C / min before 300°C. When between 300°C and 500°C, the heating rate is 1°C / min. Insulate at 500°C for 2h. A graphene-supported titanium dioxide composite material was obtained.

[0049] Polish the glassy carbon electrode with 1.0, 0.3, and 0.05 μm alumina powder in turn, then ultrasonically clean the electrode surface with deionized water f...

Embodiment 3

[0052] Graphene oxide was prepared by the improved Hummers method. Take 1 g of pre-prepared graphite oxide, disperse it in 40 mL of deionized water, and ultrasonicate for 3 h. After centrifugation, the supernatant was taken to obtain graphene oxide (GO). Take 200-400mL of absolute ethanol, add 0.5-2.0mL of potassium nitrate solution with a concentration of 0.8mmol / L, stir for 10-30min, add a certain amount of graphene oxide powder, stir for a certain period of time, slowly drop in 3-6mL of titanium Acetyl butyl ester, stirred for 10min. Aging 3-6h. Washed by centrifugation, dried, and placed in an argon atmosphere furnace. The heating rate is 2°C / min before 300°C. When between 300°C and 500°C, the heating rate is 1°C / min. Insulate at 500°C for 2h. Graphene-supported titanium dioxide composites (GO-TiO 2 ).

[0053] Polish the glassy carbon electrode with 1.0, 0.3, and 0.05 μm alumina powder in turn, then ultrasonically clean the electrode surface with deionized water fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com