Crack repair process for high-pressure turbine blade tip in gas turbine

A technology for high-pressure turbines and gas turbines, applied in the field of metal surface crack repair, can solve the problems of high-pressure turbine blade tip cracks that are rarely reported in public literature, and achieve the goal of avoiding cracks at the interface between repair welding materials and base materials, easy operation, and simple process methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

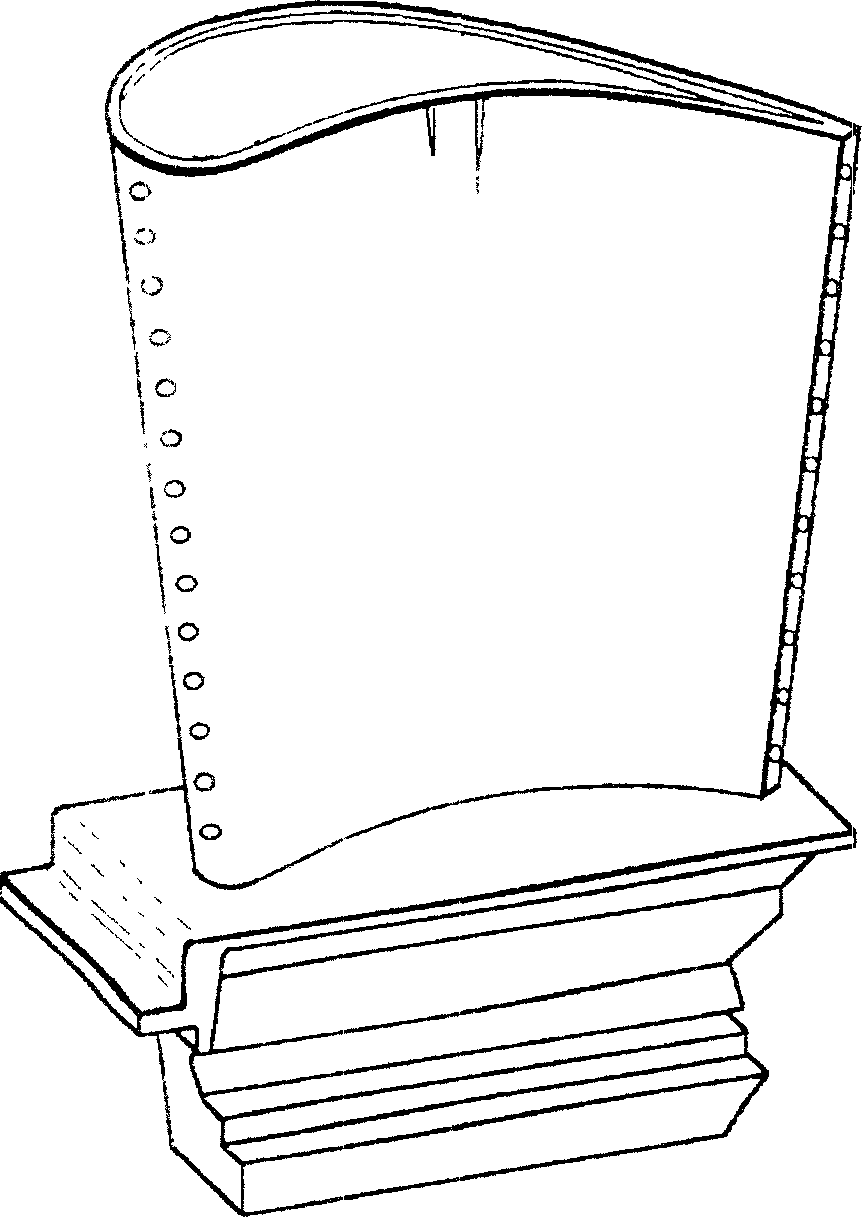

[0032] The tip crack repair of a high-pressure turbine blade of an aero-engine, the material is K465 alloy, the specific steps are as follows:

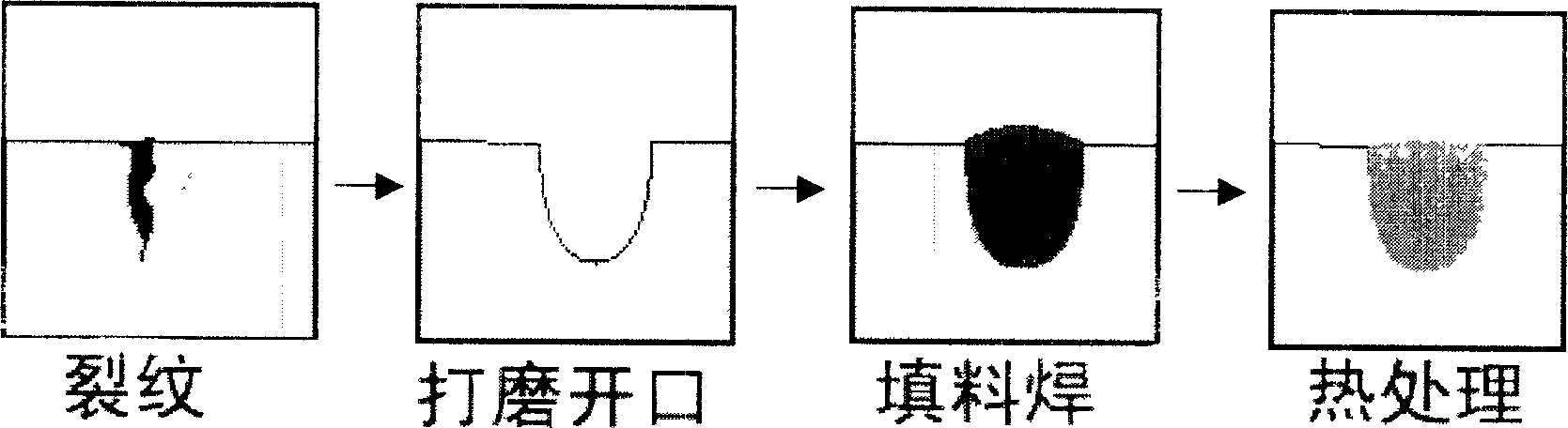

[0033] 1. According to the length and intensity of cracks on the tip of the high-pressure turbine blade, the cracks are removed by grinding in the form of openings. The maximum depth of the opening is 5mm, and the width is suitable for completely removing cracks and minimizing the loss of the base material.

[0034] 2. Under the protection of argon gas, the 3H-ES-6 metal surface strengthening repair machine developed by the Institute of Metal Research, Chinese Academy of Sciences is used for high-energy micro-arc spark (electric spark) deposition. The electrode diameter is Φ1mm, and the electrode is surfacing welding layer by layer in the repair welding area Until the entire repair welding area is filled and a grinding allowance is left.

[0035] 3. The high-energy micro-arc spark deposition material is GH44.

[0036] 4. Carry out sh...

Embodiment 2

[0042] The difference from Example 1 is:

[0043] A high-pressure turbine blade tip crack repair of an aero-engine, the blade material is Rene80, and the opening filler welding is used for repairing, the maximum opening depth is 7mm, the repair material is IN625 powder, and the average particle size is about 270 mesh. Under the protection of helium, the laser welding process is used to surfacing layer by layer in the repair welding area until the entire repair welding area is filled and a grinding allowance is left. Afterwards, grinding, testing, polishing, and shot blasting are carried out, and finally the blade is heat-treated at 1050°C for 80 hours to restore performance.

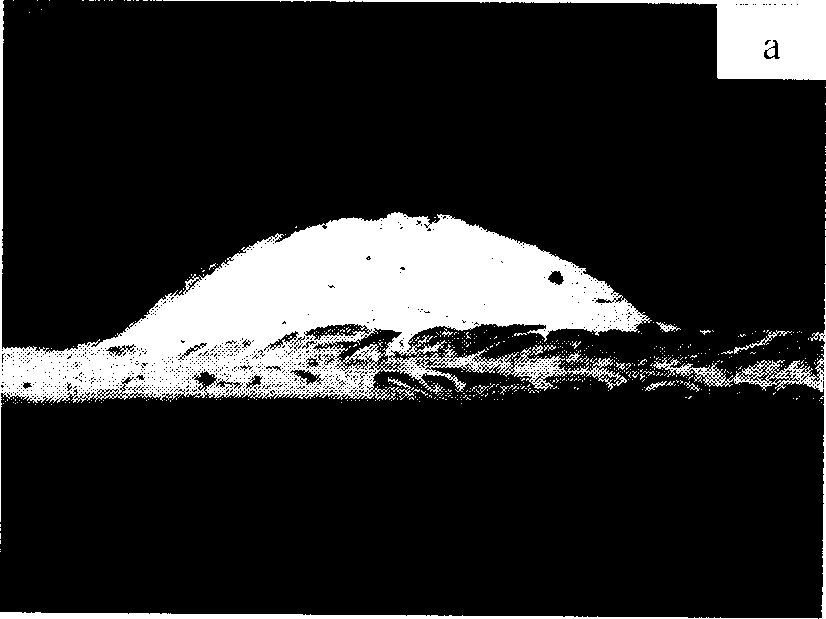

[0044] The high-pressure turbine blades repaired by this process meet the repair technical standards through X-ray and fluorescence detection.

Embodiment 3

[0046] The difference from Example 1 is:

[0047] A high-pressure turbine blade tip crack repair of an aero-engine, the blade material is K24, and the opening filler welding is used for repairing, and the maximum opening depth is 5mm. Under the protection of helium, first use the 3H-ES-6 metal surface strengthening repair machine developed by the Institute of Metal Research, Chinese Academy of Sciences to perform high-energy micro-arc spark deposition to preset the bottom layer (the electrode diameter is Φ3mm, the bottom layer height is 100um), and then use metal powder Carry out laser welding, build up welding layer by layer in the repair welding area until the entire repair welding area is filled and a grinding allowance is left. The electrodes and powder are Haynes 230. Afterwards, grinding, testing, polishing, and shot blasting are carried out, and finally the blade is heat-treated at 1180°C for 10 hours to restore performance.

[0048] In this embodiment, high-energy mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com