Silk fibroin membrane and preparation method thereof

A silk fibroin and silk fibroin technology, applied in catheters, medical science, prostheses, etc., can solve the problems of damage to nanostructures, poor mechanical properties of silk fibroin nanofiber membranes, etc., and achieve high dissolved concentration and excellent biocompatibility. and the effect of degradation performance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Natural mulberry silk was boiled with 0.5wt% sodium carbonate solution for 30 minutes, degummed, and degummed mulberry silk was obtained after repeating 3 times;

[0035] (2) Place degummed mulberry silk in 80wt% formic acid containing 2wt% calcium chloride at a concentration of 15wt%, stir and dissolve at room temperature for 2 hours, and then pour it into a polyethylene plate to dry to form a film;

[0036] (3) Soak the film in step (2) in running water for 8 hours to remove calcium chloride, then place it in a vacuum drying oven at 40°C, and dry it for 24 hours to obtain a silk fibroin film.

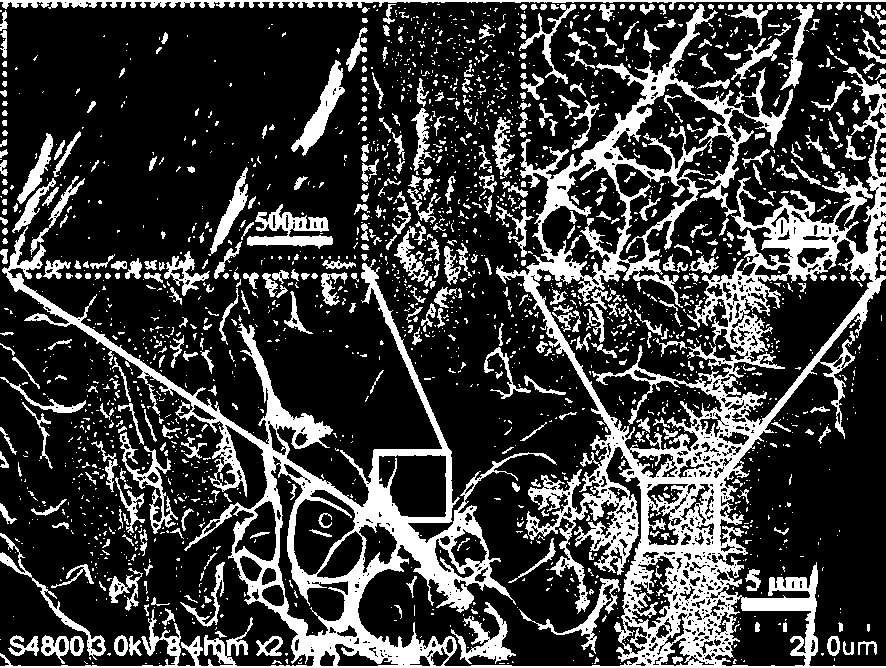

[0037] attached figure 1 , figure 2 The scanning electron microscope images of the surface and section of the above silk fibroin film are respectively; it can be seen that the surface of the silk fibroin film prepared by the present invention is smooth and smooth, and a large number of nanowire structures can be seen in the section.

Embodiment 2

[0039] (1) Natural mulberry silk was degummed by boiling 0.5wt% sodium carbonate solution for 30 minutes, and degummed mulberry silk was obtained after repeating 3 times;

[0040] (2) Place degummed mulberry silk in 95wt% formic acid containing 5wt% lithium bromide at a concentration of 20wt%, stir and dissolve at room temperature for 6 hours, and then pour it into a polyethylene plate to dry to form a film;

[0041] (3) Soak the membrane in step (2) in running water for 10 hours to remove lithium bromide, and then dry it in a vacuum drying oven;

[0042] (4) Dissolve the film in step (3) in 80wt% formic acid to prepare a 20wt% silk fibroin solution, then pour it into a polyethylene plate and dry it to form a silk fibroin film;

[0043] (5) Soak the silk fibroin film obtained in step (4) in flowing water for 1 hour to remove residual formic acid, and then vacuum-dry it at 60° C. for 20 hours to obtain a silk fibroin film.

Embodiment 3

[0045] (1) Natural mulberry silk was degummed by boiling 0.5wt% sodium carbonate solution for 30 minutes, and degummed mulberry silk was obtained after repeating 3 times;

[0046] (2) Put the degummed mulberry silk at a concentration of 10wt% in 50wt% mixed acid containing 5wt% lithium thiocyanate (phosphoric acid: formic acid = 1:4), stir and dissolve at 60°C for 1 hour, and then pour it into a polyethylene plate dry film;

[0047] (3) Soak the silk fibroin film in step (2) in running water for 1 hour to remove salt and residual acid, and then dry it in a vacuum drying oven;

[0048] (4) Dissolve the film in step (3) in hexafluoroisopropanol to prepare a 10wt% solution, and dissolve chitosan in hexafluoroisopropanol to prepare a 10wt% solution, and then mix the two solutions by 1: 1 volume blend preparation concentration is 10wt%, silk fibroin and polylactic acid 1:1 blended silk fibroin solution;

[0049](5) Pour the silk fibroin / chitosan blended silk solution prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com