Cutting insert and cutting tool

A cutting insert and cutting tool technology, applied in the field of cutting tools and cutting inserts, can solve problems such as cutting edge damage, and achieve the effect of reducing cutting resistance and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

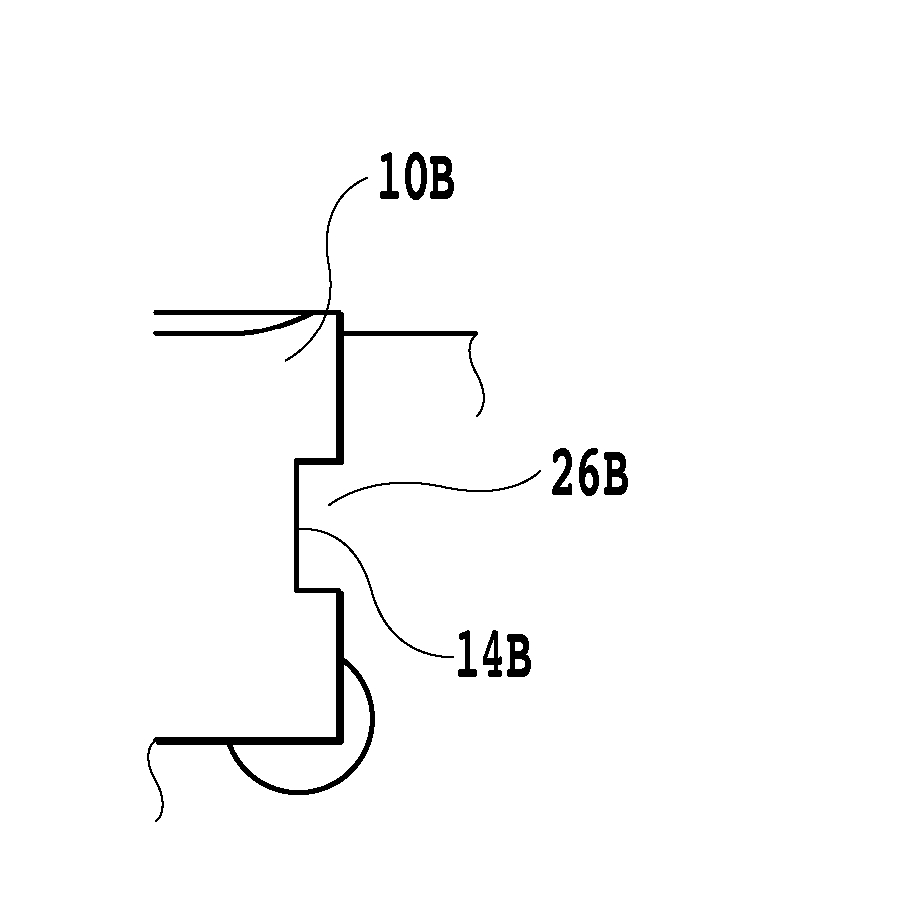

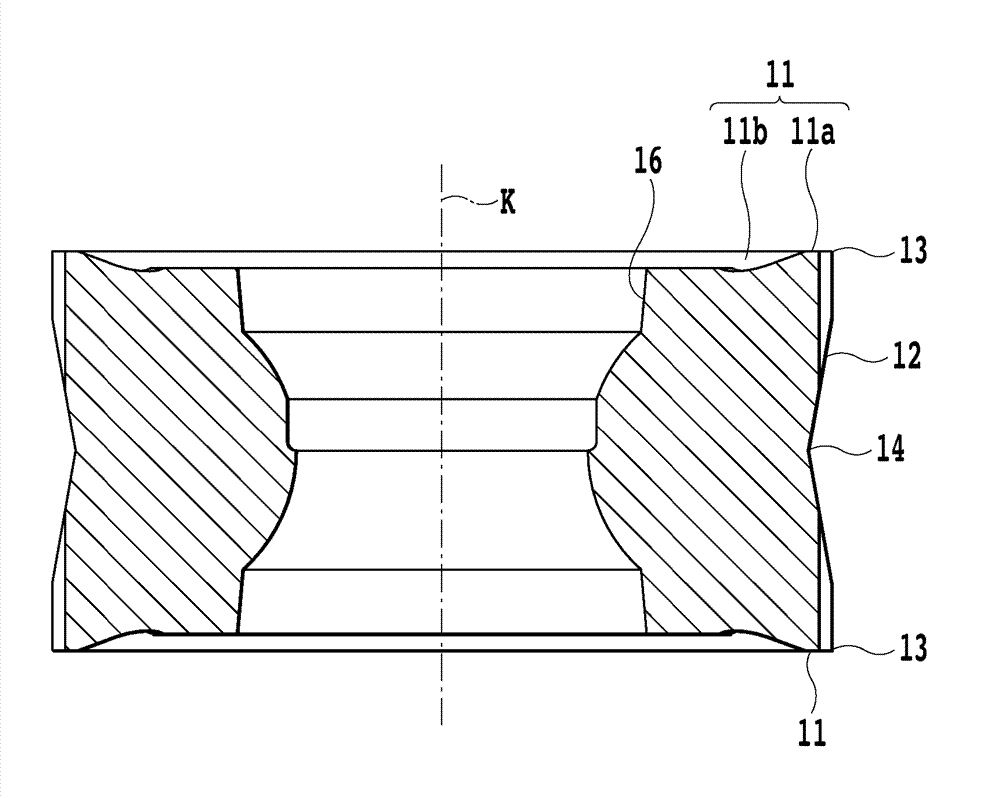

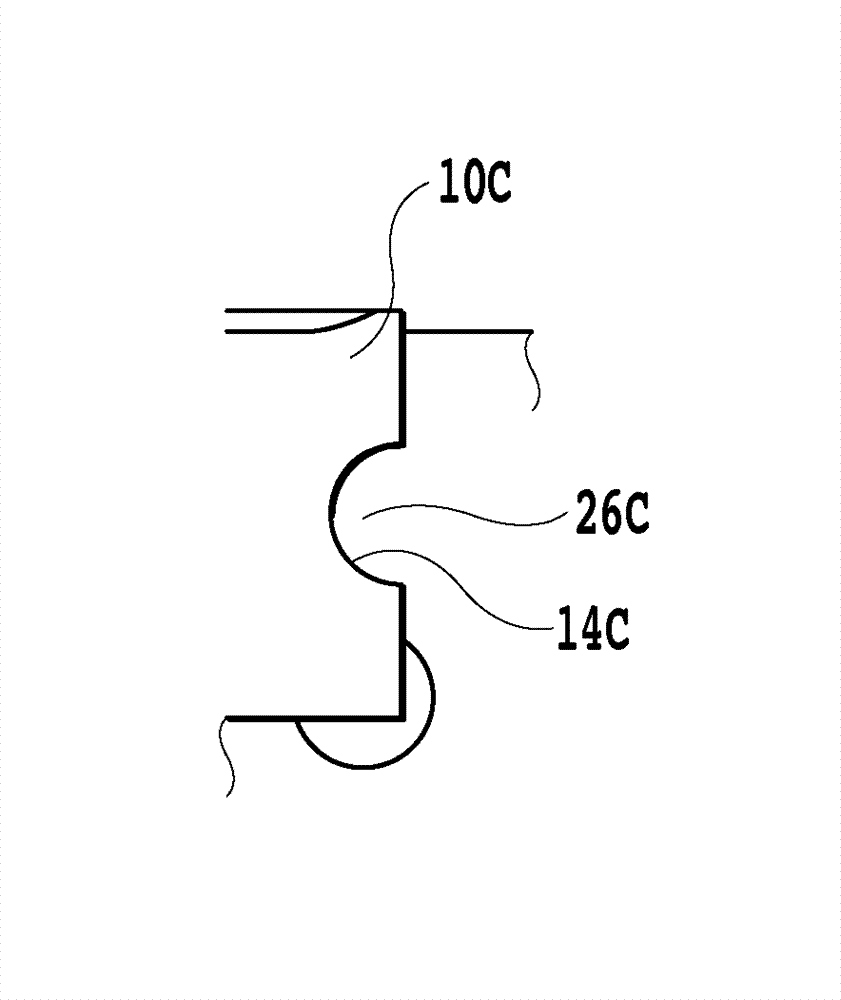

[0034] Refer to the following Figure 1 to Figure 8 One embodiment of the present invention will be described.

[0035] figure 1 as well as figure 2 The cutting tool 20 shown is a high feed cutter comprising a cutting tool body 21 and a plurality of cutting inserts 10 .

[0036] The cutting tool body 21 of the cutting tool 20 is as Figure 4 As shown in FIG. 21 , it has a substantially cylindrical shape, and a coupling hole 23 for coupling with a machine tool is provided in the center portion of the cutting tool body 21 to penetrate from the rear end to the tip. Furthermore, the cutting tool body 21 has a plurality of mounting seats 22 formed at equal intervals in the circumferential direction centering on the central axis J. As shown in FIG. The cutting insert 10 described later is attached to each of the plurality of mounts 22 . The cutting insert 10 is fixed to the cutting tool body 21 by bolts BT. In front of the mounting seat 22 formed at the tip of the cutting too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com