Vertical semiautomatic pineapple peeling machine

A semi-automatic, peeling machine technology, applied in peeling appliances, household appliances, applications, etc., can solve the problems of residue, loss of rest time, slow operation process, etc., and achieve high rigidity, high efficiency, and stable transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

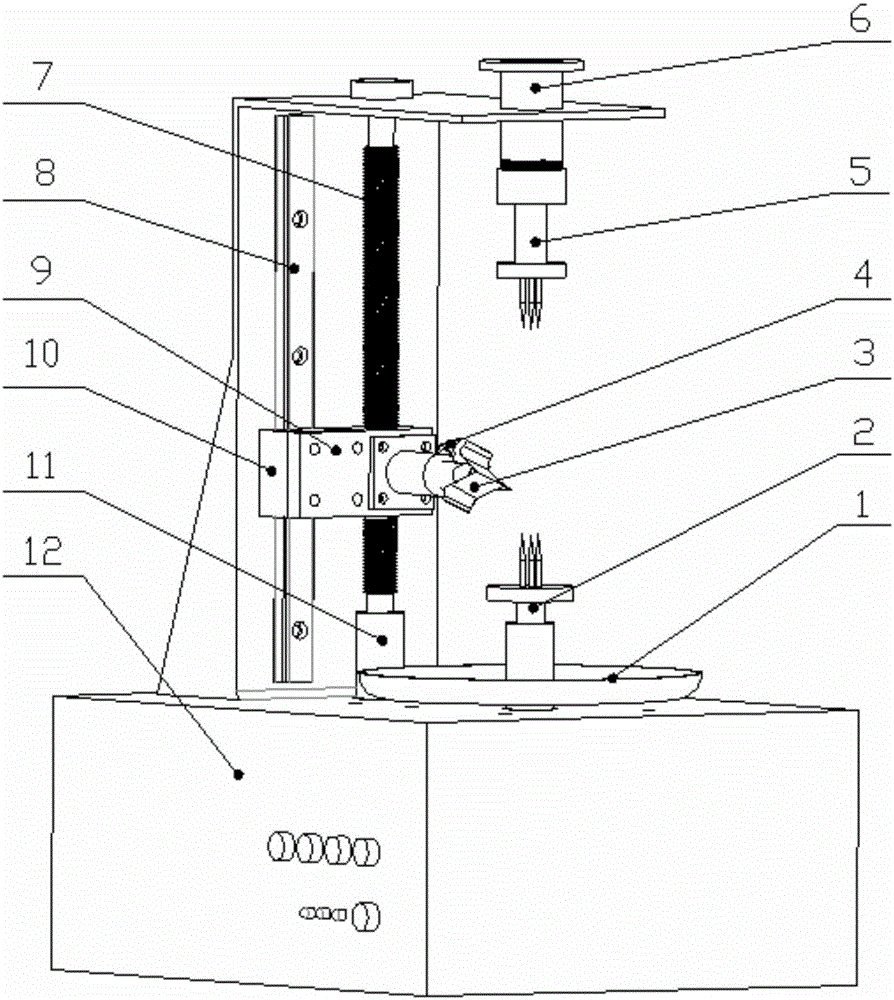

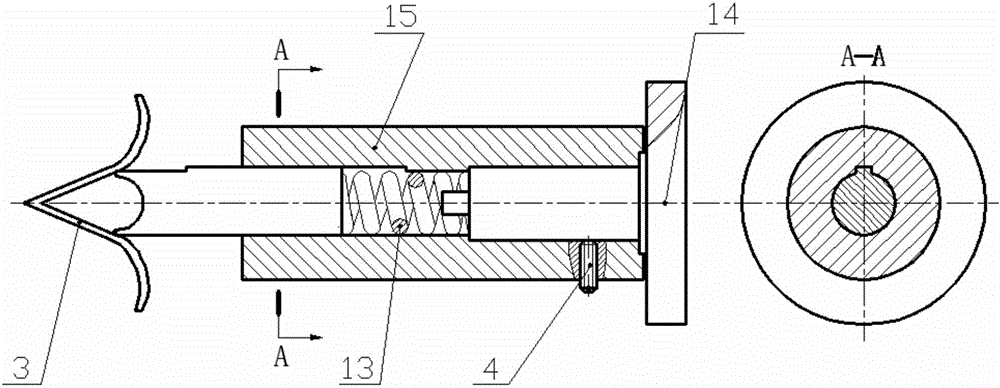

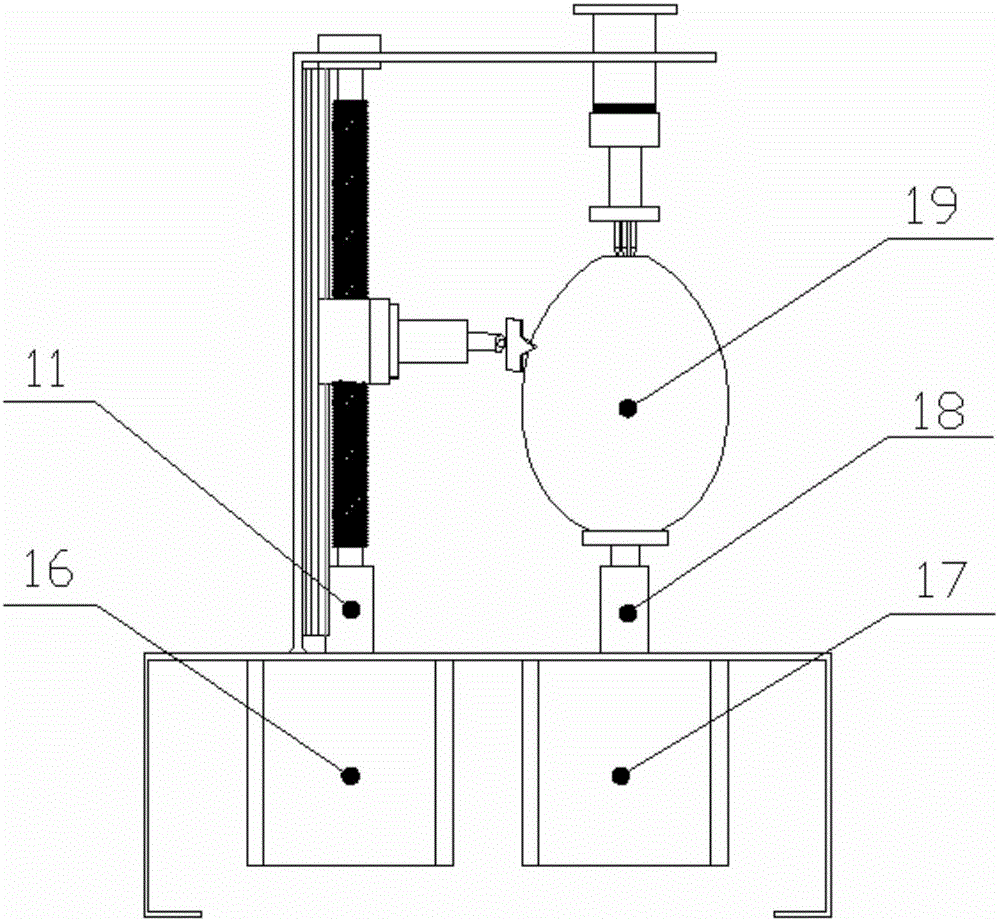

[0031] Such as Figure 1 to Figure 6 Shown, vertical semi-automatic pineapple peeling machine of the present invention comprises sliding screw nut transmission mechanism, cutter system, pineapple rotating mechanism and frame 12, and concrete structure and connection relation are:

[0032] Described sliding lead screw nut transmission mechanism comprises leading screw motor 16, A type key, coupling 11, leading screw 7, leading screw slide table 9, hexagonal bolt, slide rail 8 and slide block 10, described leading screw motor 16 The coupling 11 and the coupling 11 and the lead screw 7 are connected by A-type keys; the lead screw slide table 9 is fixed on the slider 10 through hexagonal bolts, and through the fixed connection with the slider 10, the tool 3 is driven to reciprocate together ; The slide rail 8 is fixed on the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com