Tunneling device for hard rock body

A rock mass, hard technology, applied in the field of tunneling equipment, can solve the problems of increased tool wear, increased safety hazards, reduced reliability and work efficiency, etc., to reduce the cutting resistance, improve the crushing efficiency, and reduce the difficulty of crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

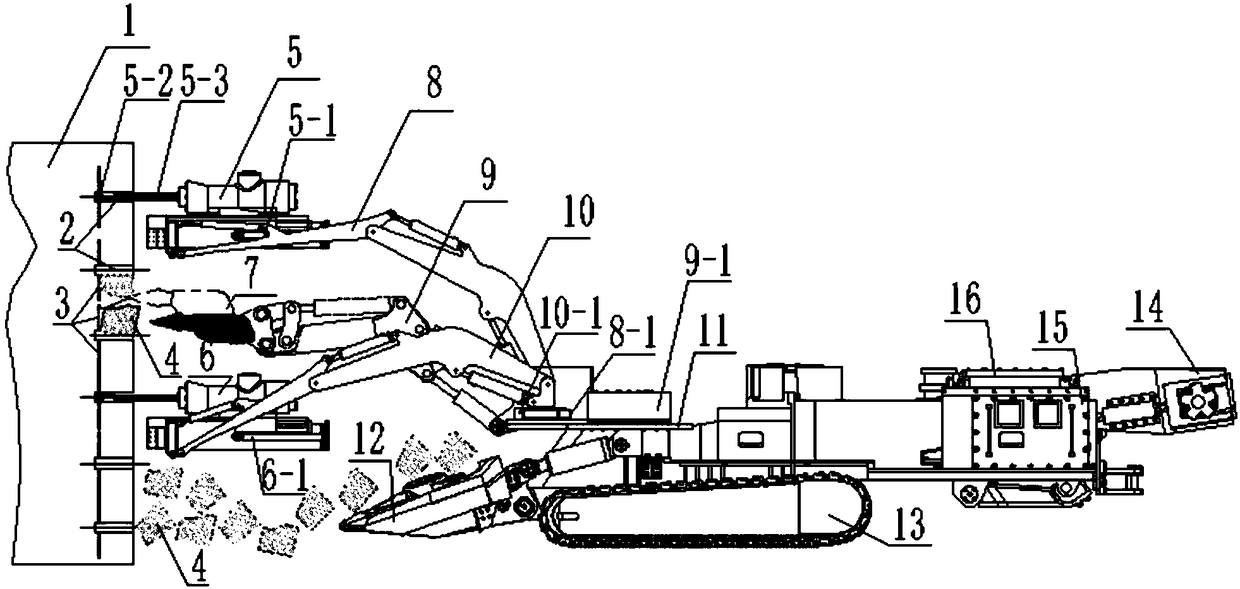

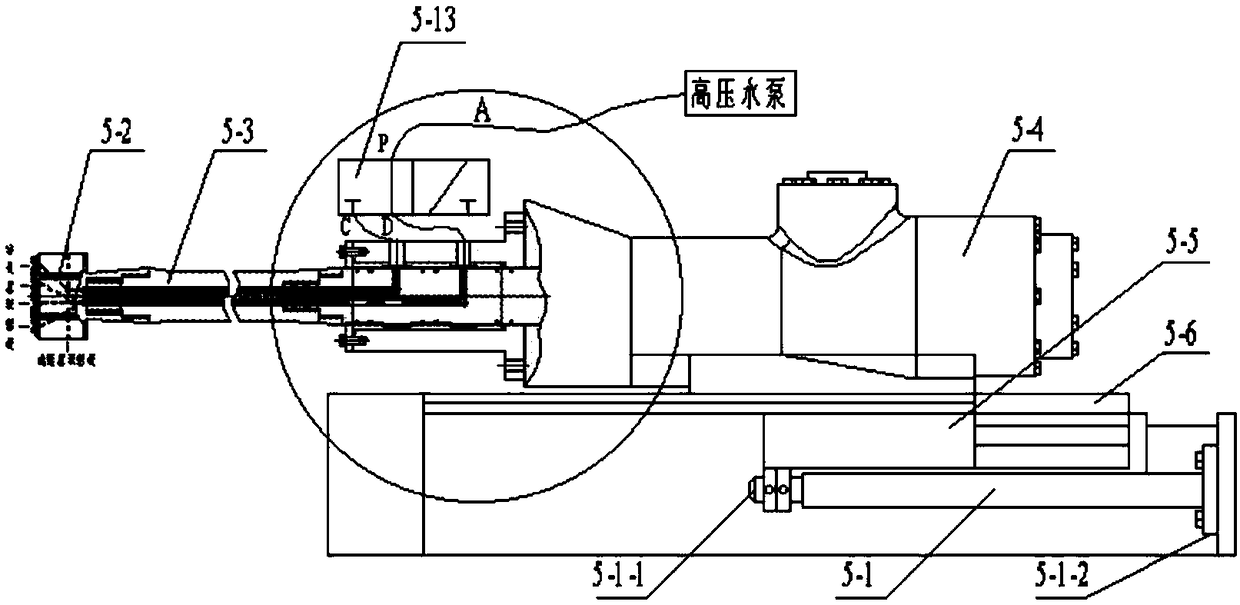

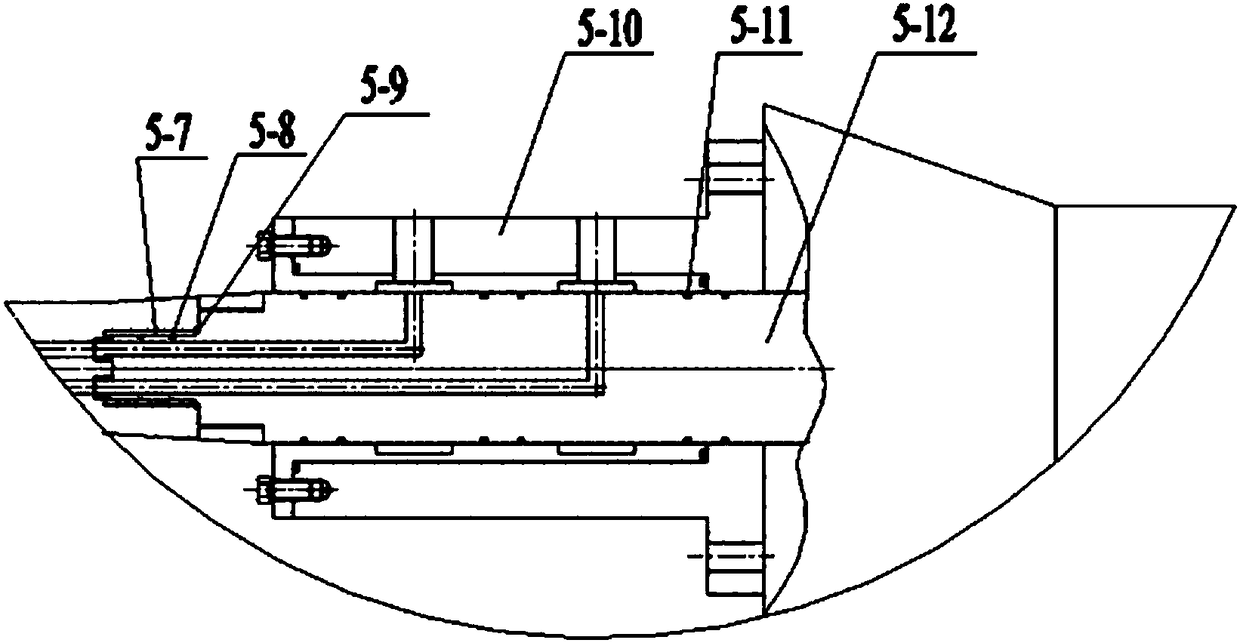

[0025] Embodiment 1: as Figure 1 to Figure 3As shown, the excavation equipment for a hard rock mass of the present invention mainly includes a right rock mass drilling and crevice abrasive jet mechanism 5, a left rock mass drilling and crevice abrasive jet mechanism 6, a hydraulic impact hammer 7, and a right multi-degree-of-freedom machine Arm 8, middle multi-degree-of-freedom mechanical arm 9, left multi-degree-of-freedom mechanical arm 10, main body frame 11, loading mechanism 12, crawler belt traveling mechanism 13, conveying mechanism 14, high-pressure abrasive jet generation system 15, hydraulic pump station 16. The loading mechanism 12, the conveying mechanism 14, the high-pressure abrasive jet generation system 15, and the hydraulic pump station 16 are all installed on the main body frame 11, the right multi-degree-of-freedom mechanical arm 8, the left multi-degree-of-freedom mechanical arm 10 and the middle multi-degree-of-freedom mechanical arm The mechanical arm 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com