Preparation method of finished cigarette empty cylinder and preparation device thereof

A technology for finished cigarettes and cigarettes, applied in the preparation of test samples, etc., can solve the problems of changing the ventilation rate of cigarette filters, unfavorable objective evaluation, low production efficiency, etc., and achieve accurate drilling depth, simple structure, high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

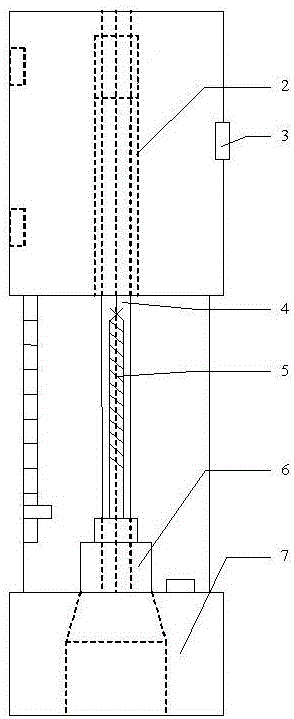

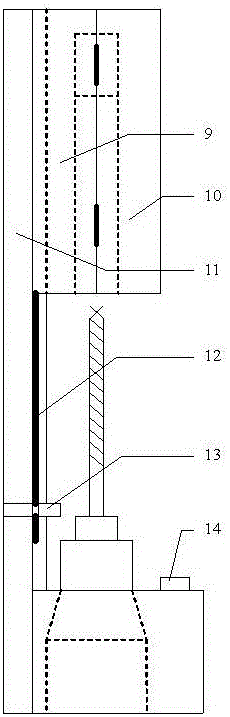

[0021] A kind of embodiment of the preparation method of finished cigarette empty cylinder of the present invention comprises the following steps:

[0022] (1) Hold the finished cigarette with the burning end facing down and set up vertically;

[0023] (2) Adjust the position height of the limit block used to limit the drilling depth of the drill bit in the cigarette according to the length of the tobacco filling section in the finished cigarette;

[0024] (3) Use a drilling tool to drill out the shredded tobacco in the finished cigarette to obtain the empty tube of the finished cigarette.

[0025] In other embodiments of the method for preparing the empty barrel of the finished cigarette of the present invention, step (2) in the above embodiment can also be set before step (1), that is, the drilling depth is set first, and then the cigarette is clamped Of course, the step (2) in the above embodiment can also be omitted, and the drilling depth of the drill bit in the cigarett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com