A square hole drilling rig

A square hole drilling rig, square hole technology, applied in boring/drilling, portable drilling rig, drilling/drilling equipment, etc. Can not effectively drill square holes and other problems, to achieve the effect of sufficient positioning rigidity, small error and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

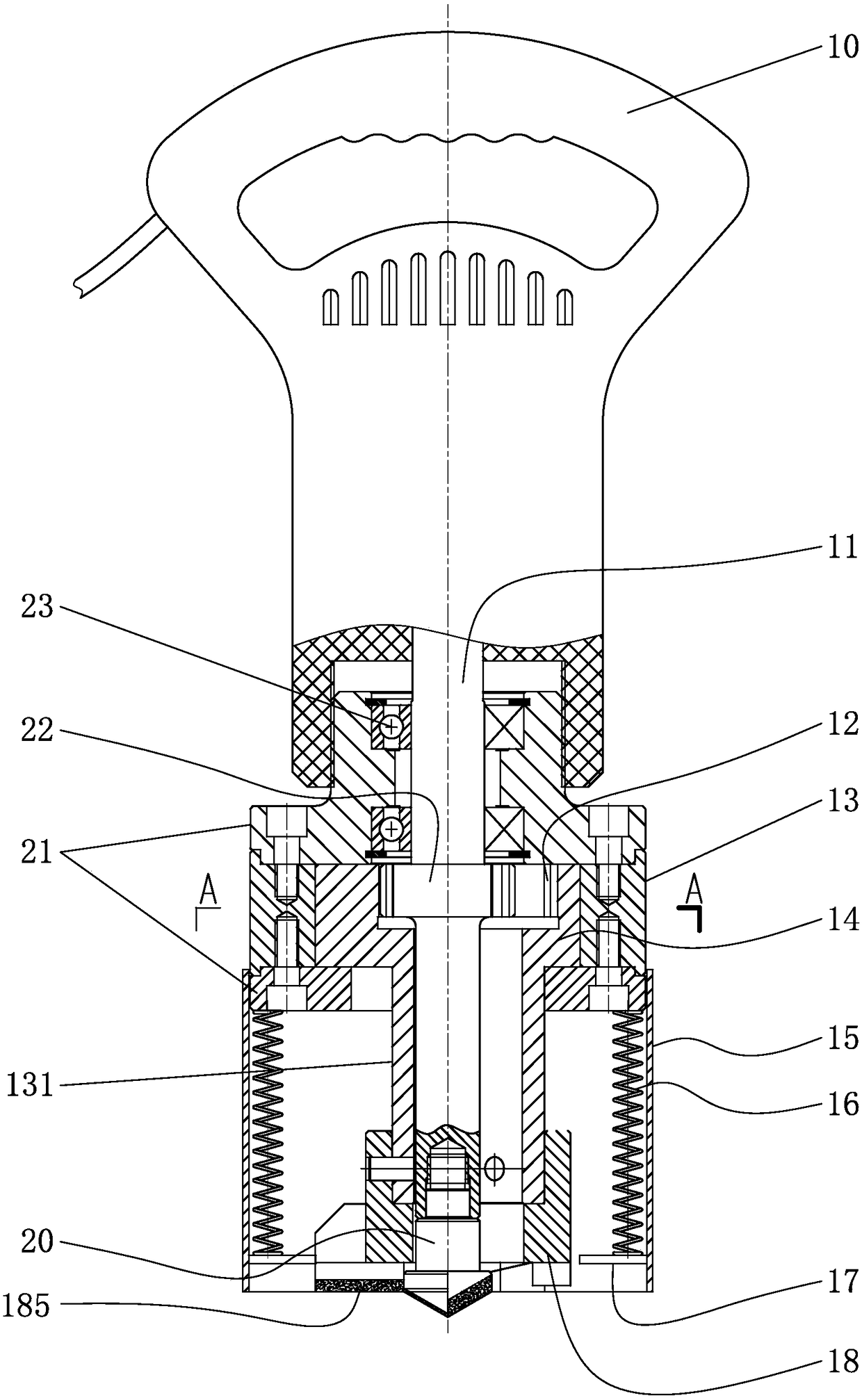

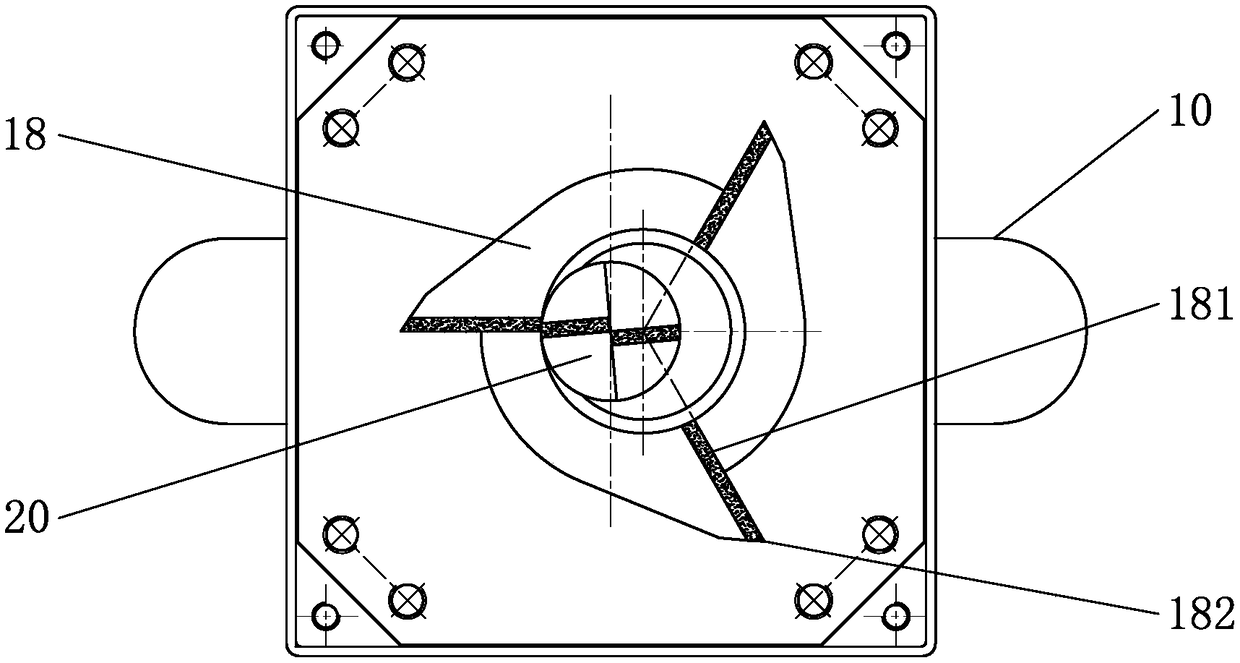

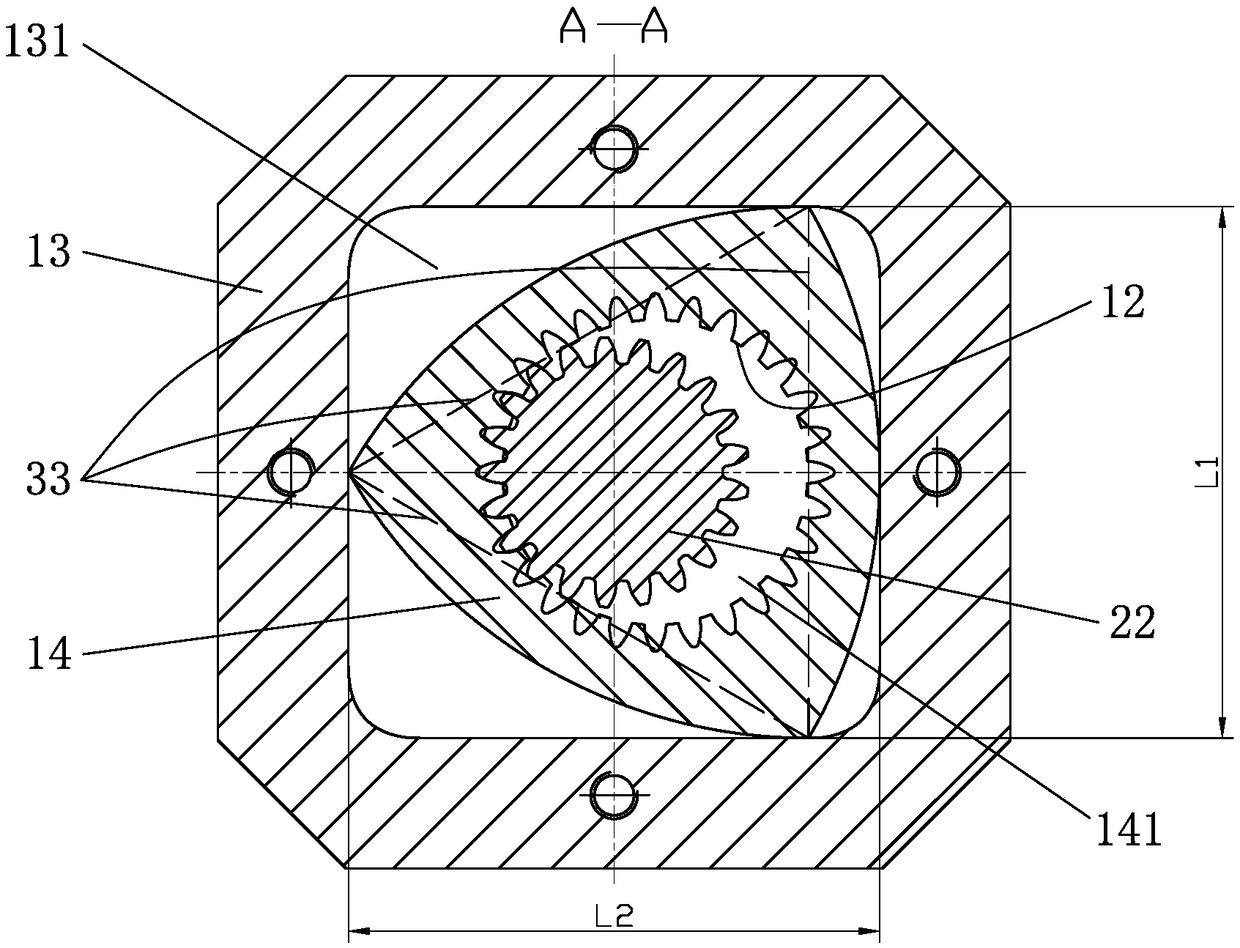

[0031] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 9 :

[0032] A square hole drilling machine, comprising a housing 21 and a drill bit, the drill bit is a pointed centering drill bit 20, the driving rod 11 installed in the middle of the housing 21 is supported on the housing 21 through a bearing 23, the lower end of the driving rod 11 The centering drill bit 20 is fixed coaxially, and the middle part of the driving rod 11 is provided with a pinion 22 with external teeth, and the outside of the pinion 22 is sleeved with a Relo triangular block 14 with an internal gear 12 (the described The outer contour of the Lelo triangle block 14 is a Lelo triangle, so claim the Lelo triangle block 14). The frame 13 is fixed on the housing 21, the axis center of the pinion 22 coincides with the center of the guiding frame 13, the pitch circle diameter of the internal gear 12 is larger than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com