Insulating product

一种产品、芯层的技术,应用在分层产品、金属层状产品、通过隔热保护管道等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

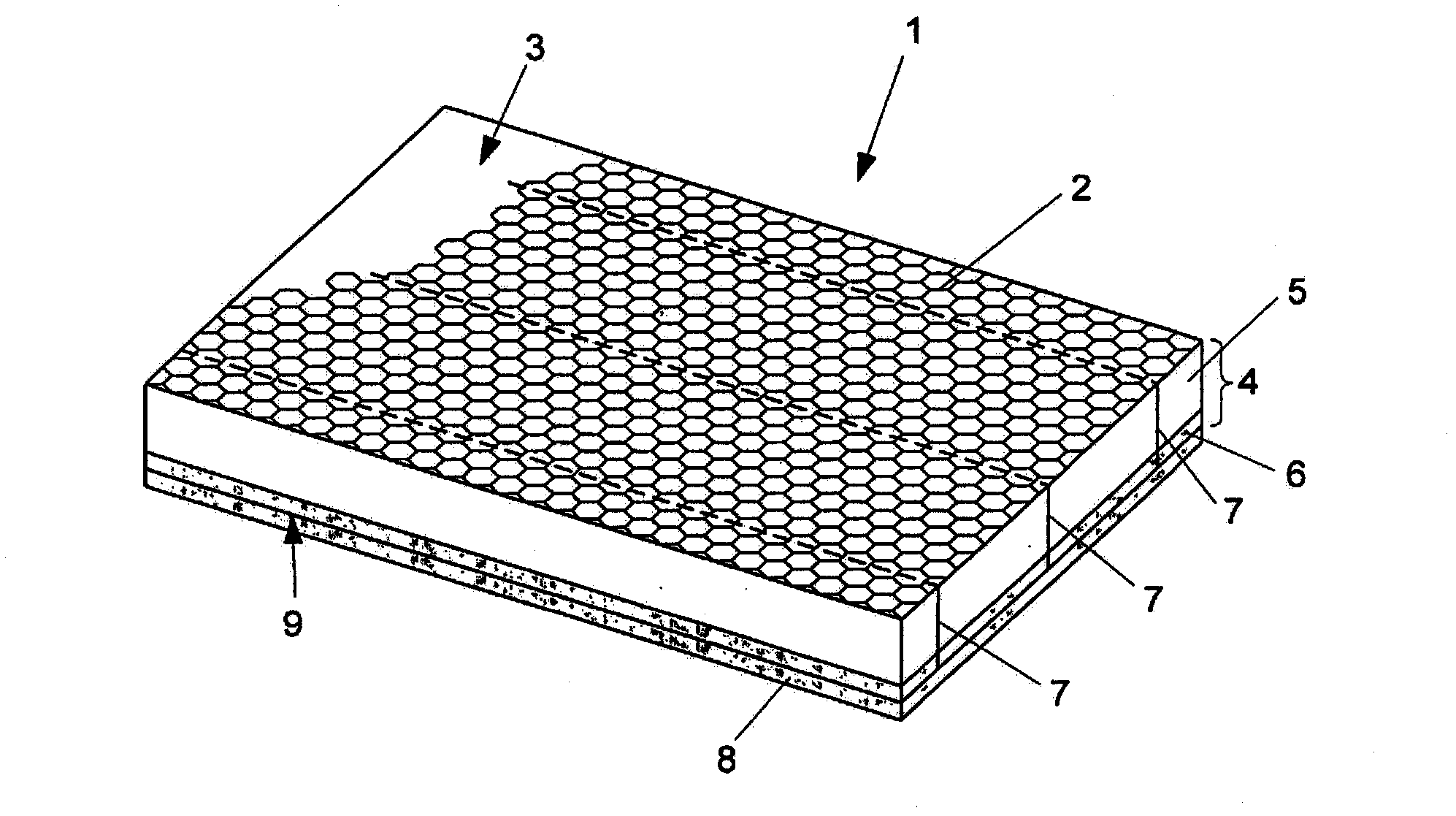

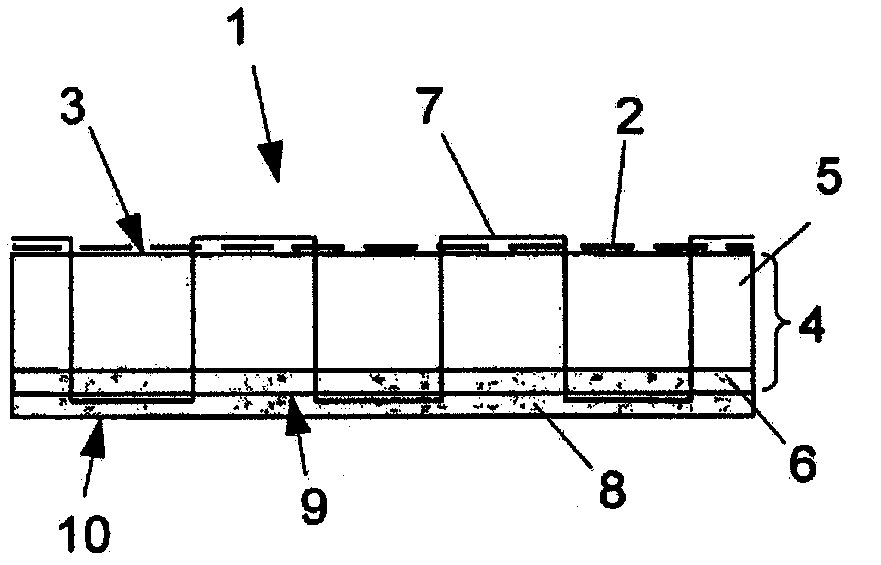

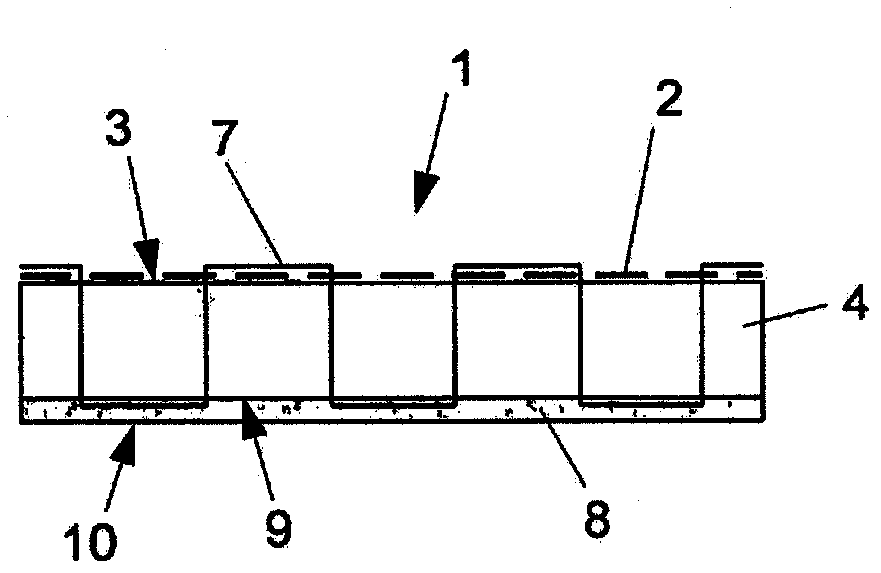

[0038] figure 1 A first embodiment of a flexible insulation product 1 according to the invention is shown. Since the product 1 is provided with a flexible wire mesh 2 on the first side 3 of the flexible insulating core layer 4, the product 1 is a so-called wire mesh mat. In this first embodiment, the insulating core 4 comprises two layers, namely a first core 5 comprising mineral wool and a flexible airgel matrix composition comprising preferably an airgel reinforced with mineral fibres. The second core layer 6 is reinforced. The first core layer 5 and the second core layer 6 are interconnected to the wire mesh 2 by means of a plurality of metal wires 7 which are stitched through the wire mesh 2 and the first core layer 5 and the second core layer 6 . The flexible insulating cover layer 8 is fixed to the second side 9 of the insulating core layer 4 (i.e. the second core layer 6 on the bottom surface).

[0039] exist figure 1 In the embodiment shown in , the flexible insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com