An improved process for producing silica aerogel thermal insulation product with increased efficiency

A technology of silica and production process, which is applied in the direction of airgel preparation, layered products, and protection of pipelines through heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

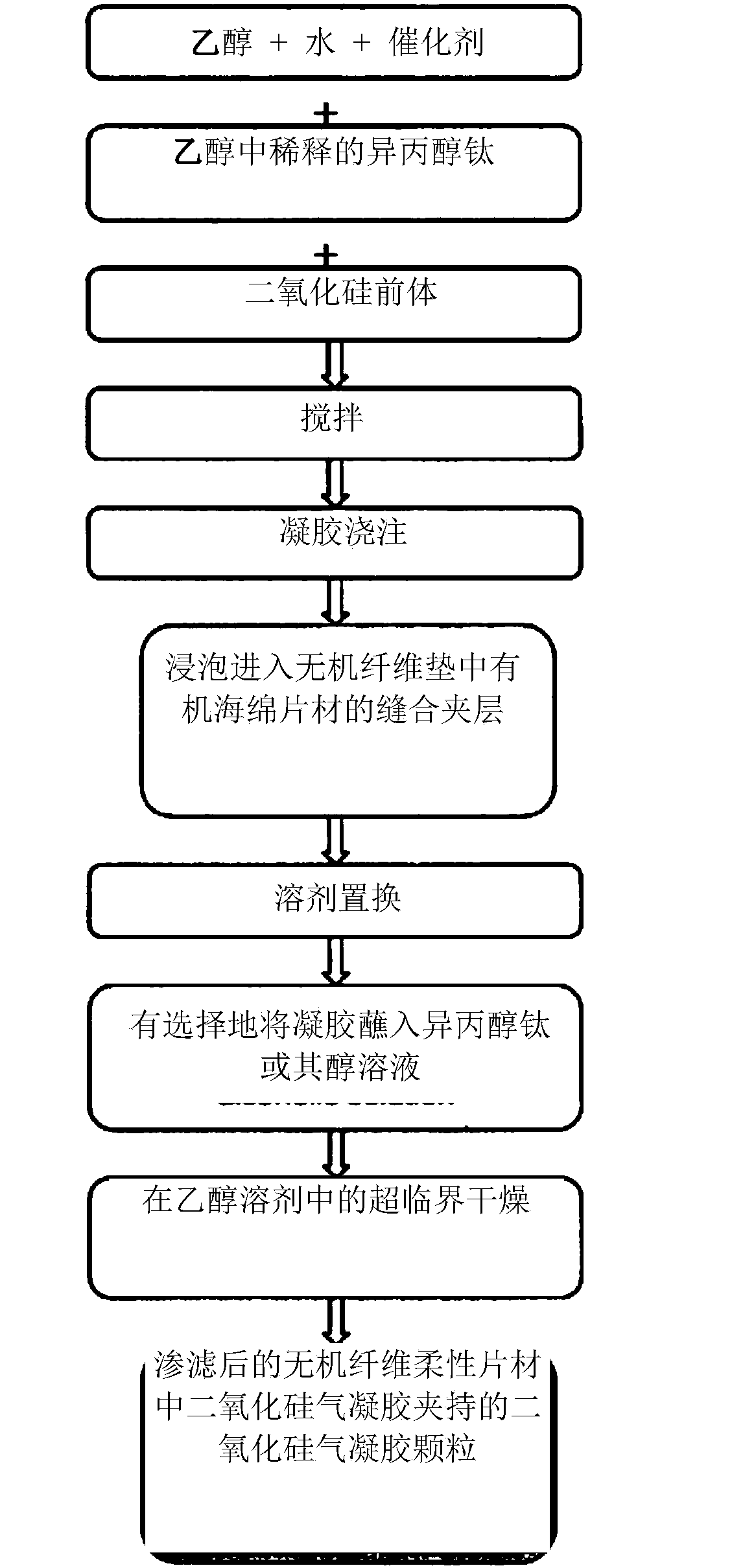

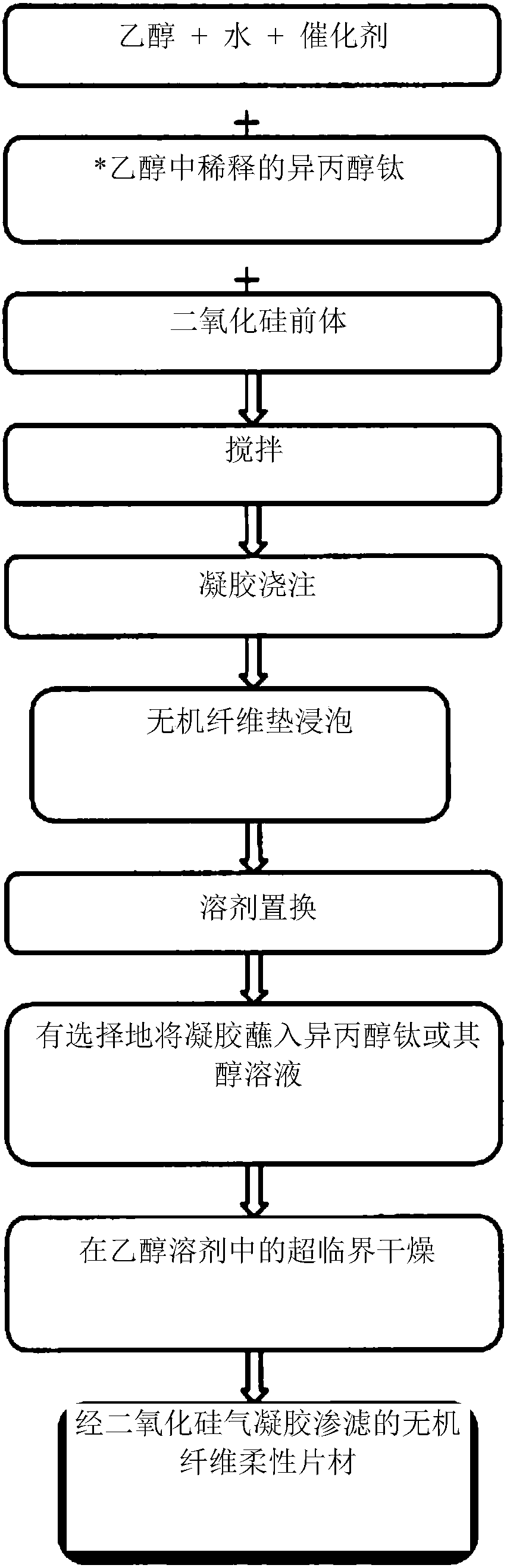

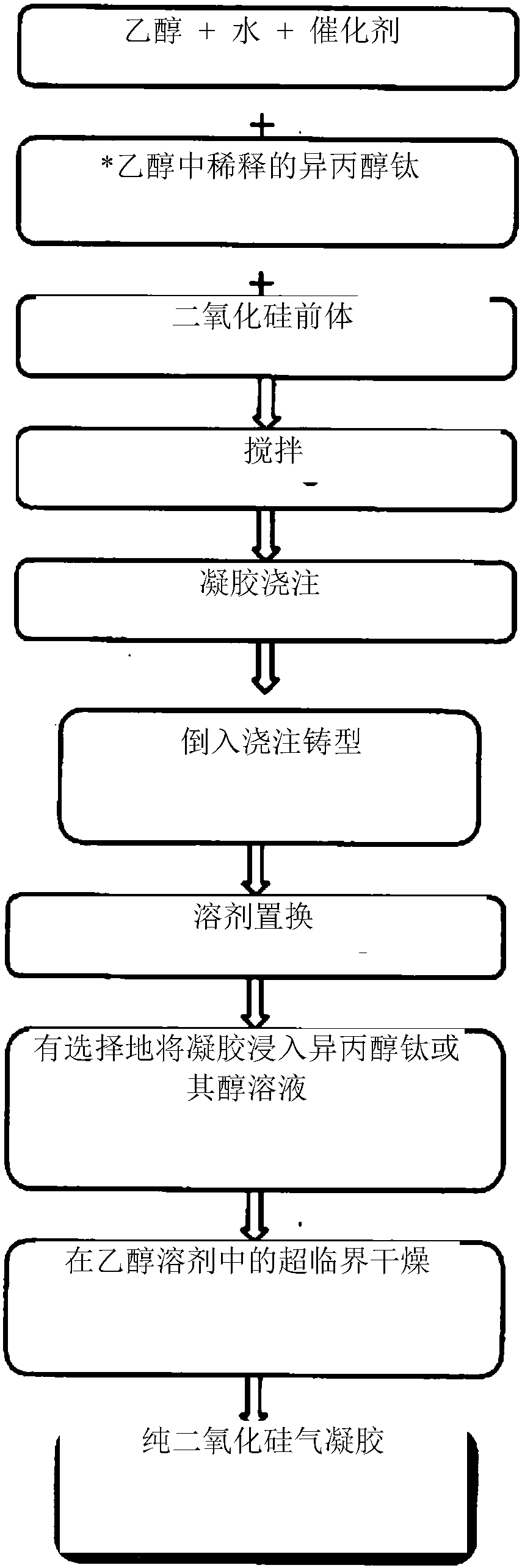

Method used

Image

Examples

Embodiment 1

[0107] In the first step, weigh 412 milliliters of ethanol, 385 milliliters of distilled water, 16.5 milliliters of ammonium fluoride (0.5M) and 1.65 milliliters of ammonia solution, and pour them into a stirring flat round bottom flask. Dilute 2.75 ml of titanium isopropoxide into 165 ml of ethanol, and slowly add the dilution to the above mixture. While stirring, 275 ml of tetraethoxysilicate and 110 ml of methyltrimethoxysilane were added to the above mixture. The resulting sol was transferred to a plastic container, which converted to a gel within 5-7 minutes. Store shaped gels at room temperature for 1 day to strengthen the gel network. Finally, the gel was removed from the plastic container and immersed in ethanol for 3 days in order to replace the liquid and by-products in the gel. The stock ethanol was replaced daily with fresh batches of ethanol. Then, the gel is placed in a high-pressure reactor for high-temperature supercritical drying. Reactor temperature and p...

Embodiment 2

[0109] In the first step, weigh 375 milliliters of ethanol, 350 milliliters of distilled water, 25 milliliters of ammonium fluoride (0.5M) and 1.5 milliliters of ammonia solution in a stirring beaker. Dilute 5 ml of titanium isopropoxide into 150 ml of ethanol, and slowly add the resulting dilution to the above mixture. While stirring, 250 ml of tetraethoxysilicate and 100 ml of methyltrimethoxysilane were added to the mixture. This sol was soaked on a 10 mm thick ceramic fiber nonwoven cloth with a size of 30 cm x 30 cm. Within 5-10 minutes, the sol soaked in the fiber blanket solidifies. The resulting composite gel can be aged in a sealed plastic container to allow the gel network to remain at room temperature for 1 day. Finally, the composite gel was taken out of the plastic container and immersed in ethanol for 3 days to replace the liquid and by-products in the gel. The stock ethanol was replaced daily with fresh batches of ethanol. Then, the gel is placed in a high-p...

Embodiment 3

[0111] According to the silica airgel prepared by the steps described in Example 2, in addition to 5 milliliters of titanium isopropoxide, 0.5 milliliters was added to the final product so that there was about 0.1% titanium dioxide in the final product. In another experiment, no titanium isopropoxide was added in order to obtain a pure silicon aerosol flexible sheet sample without addition of titanium dioxide. Samples with 0.1% titanium dioxide and samples without titanium dioxide were tested for reflectance of infrared radiation by heating to 400° C. in air. Figure 4 It was shown that due to the presence of titanium dioxide (titanium dioxide concentration ≤ 1% compared to samples without titanium dioxide), the infrared reflectivity in the wavelength range of 3nm-7pm was increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com