Method utilizing expanded perlite to produce vacuum insulated plate

A technology of expanded perlite and vacuum insulation panels, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of environmental protection, high energy consumption, high material cost, etc., and achieve reduced raw material costs and low thermal conductivity Coefficient, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

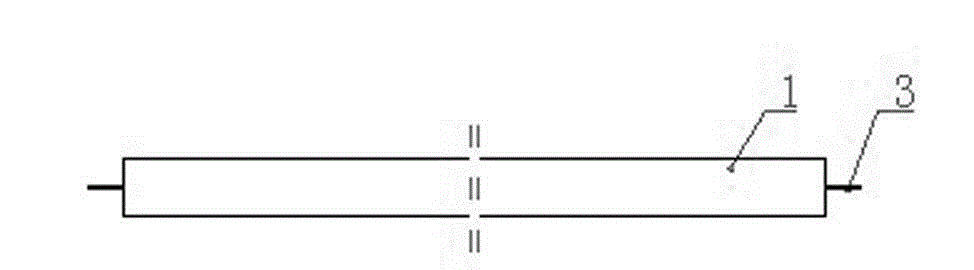

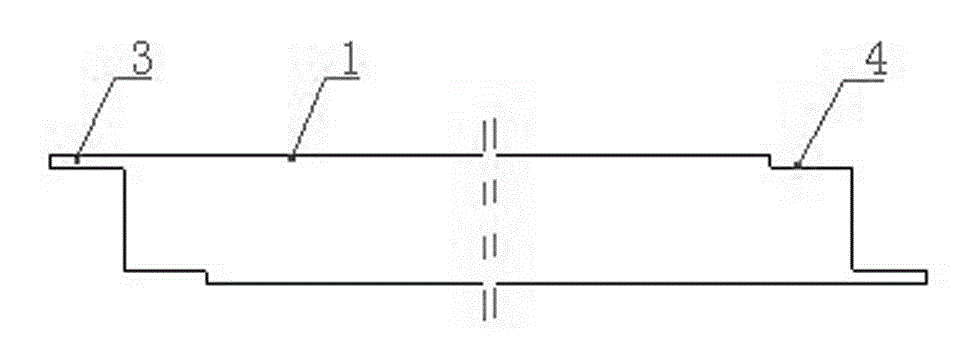

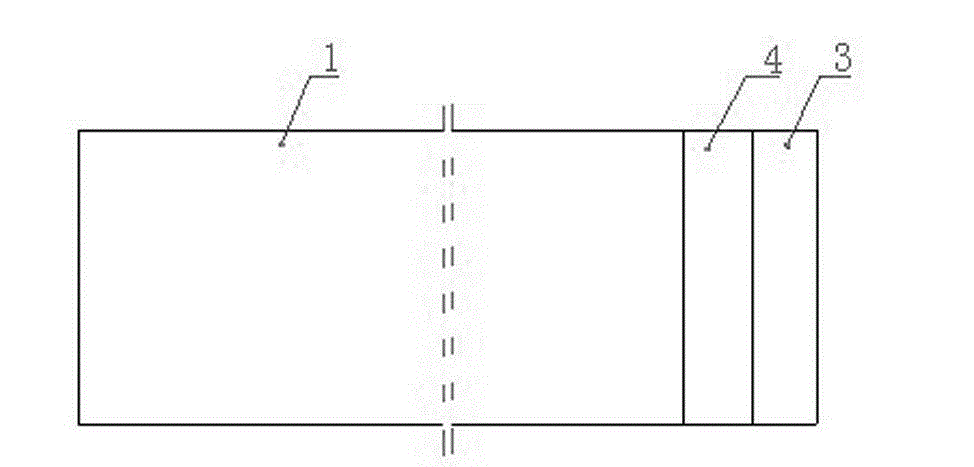

[0028] The invention discloses a method for producing a vacuum insulation panel by using expanded perlite. The core material is put into a high-barrier gas film bag and sealed after vacuuming. It is characterized in that the composition and parts by weight of the core material are: expanded pearl Rock 55-75, auxiliary material 8-20, fiber 5-10, vacuum active stabilizer 3-7.

[0029] The manufacturing process includes the following steps:

[0030] (1) Ingredients: Put various materials of the formula into the mixer for thorough mixing.

[0031] (2) Drying: Dry the evenly stirred mixture, and control the drying temperature at 100-120°C. During the drying process, measure the moisture content of the mixture every 8 minutes until the moisture content of the mixture reaches 0.5 % below, stop drying.

[0032] (3) Non-woven bag making: The non-woven fabric is made into a three-side-sealed bag, or a three-side-sealed bag with gussets.

[0033] (4) Filling of core material: Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com