Insulated cargo container and methods for manufacturing same using vacuum insulated panels and foam insulated liners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

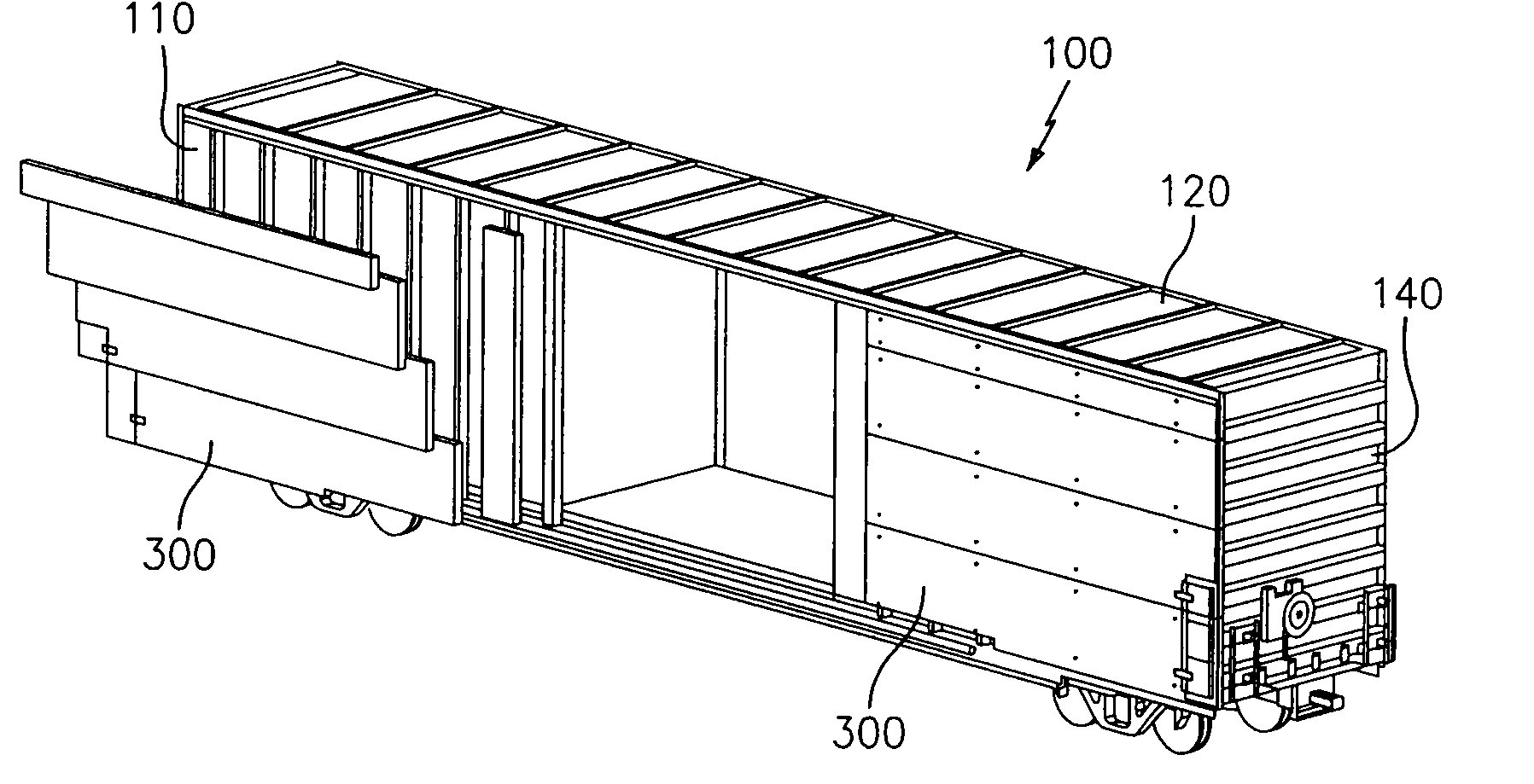

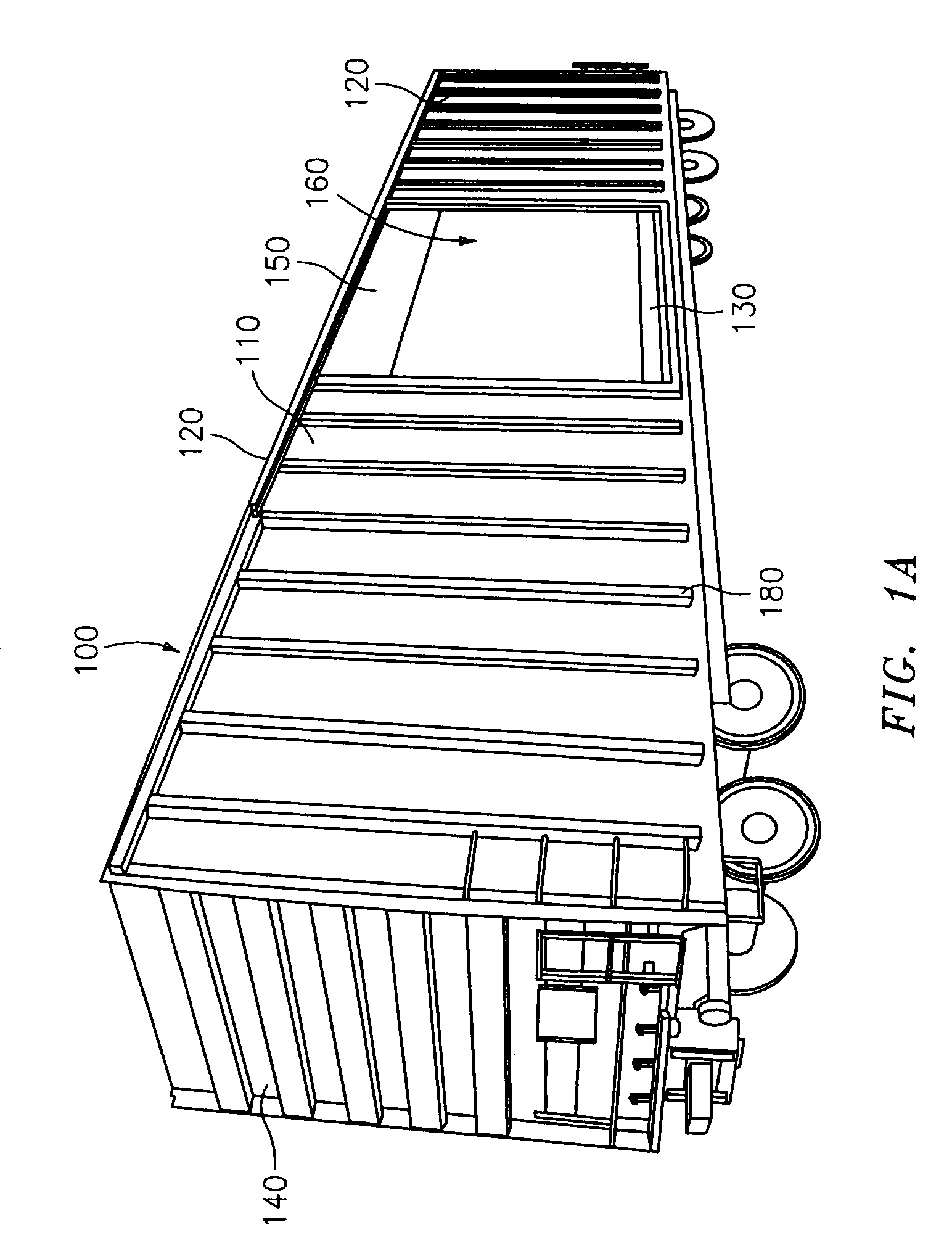

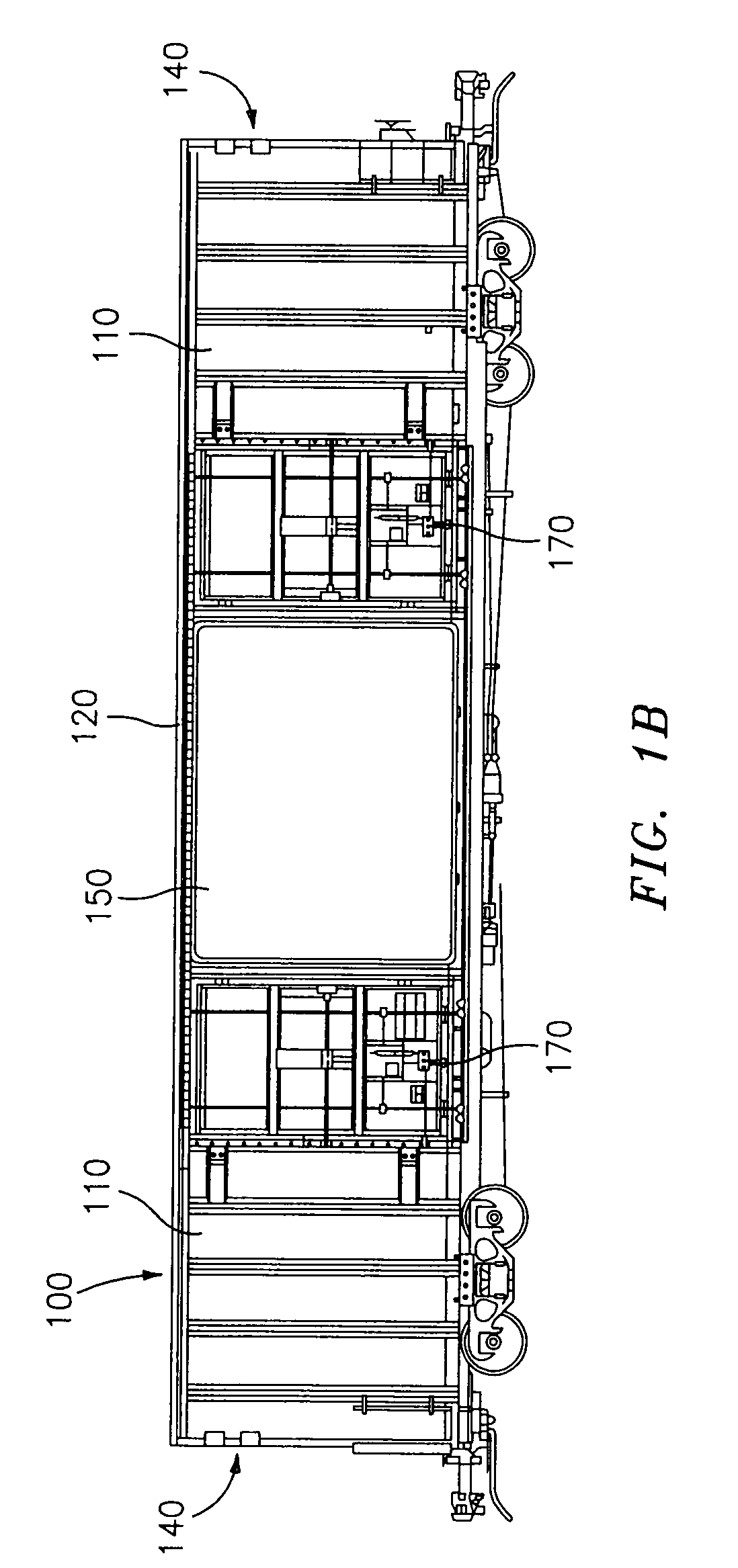

[0038]The present disclosure describes an existing cargo container, e.g., a boxcar, and method(s) for insulating the cargo container. FIGS. 1A-6 illustrate the cargo container to be modified consistent with the method(s) described herein. The invention as claimed, however, is broader than boxcars and extends to the modification of other large insulated cargo containers, such as, shipping containers used on seagoing container vessels, truck trailers, straight trucks, refrigerated buildings, or the like. In addition, the boxcars described herein may include refrigeration components as known to one of ordinary skill in the art such that the refrigerated boxcars may be insulated using the insulating panels and liners described herein. Such insulating panels and liners may be modified as understood by one of ordinary skill in the art to accommodate refrigerator units, air plenums and other structural and mechanical components as well as design features commonly attributable to refrigerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Abrasion resistance | aaaaa | aaaaa |

| Flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com